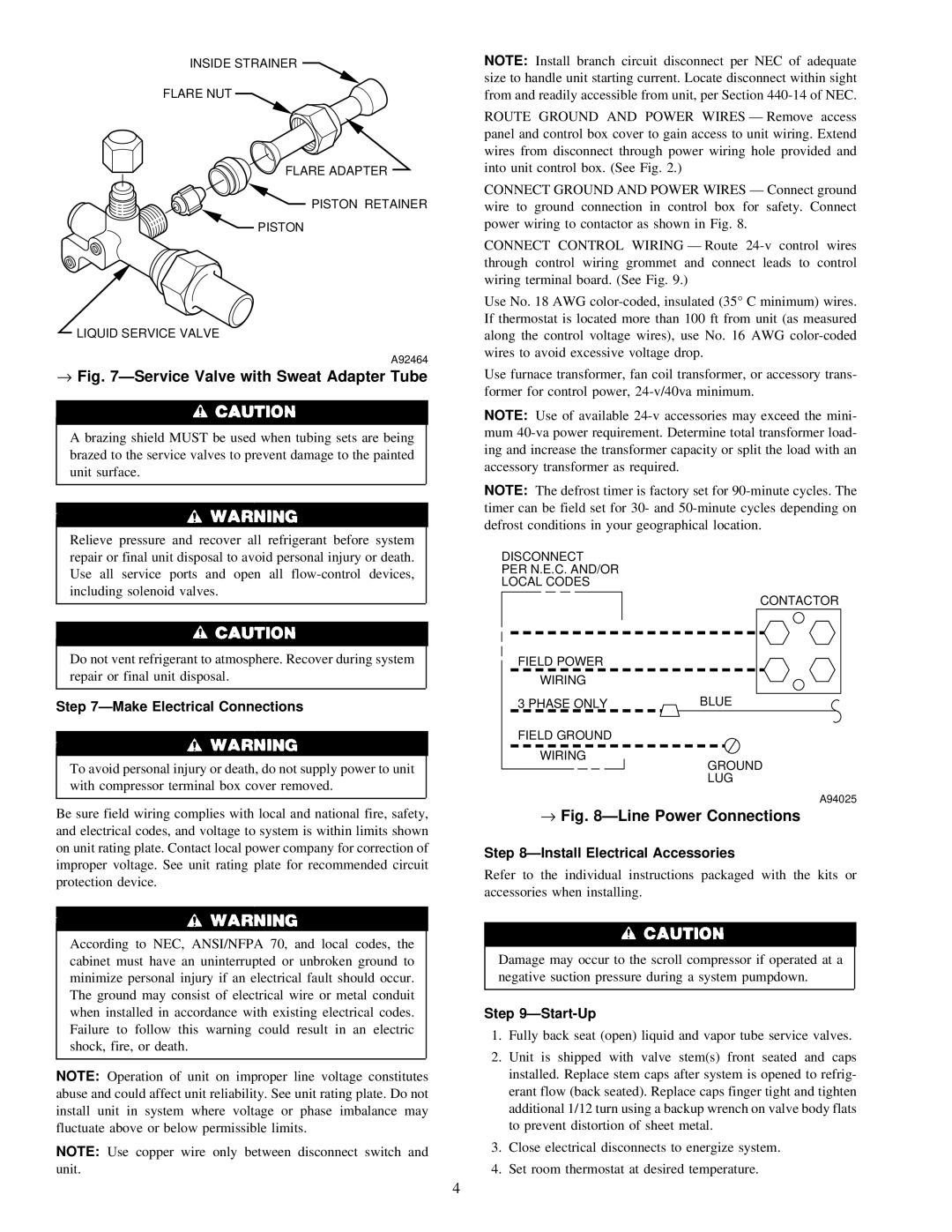

INSIDE STRAINER ![]()

FLARE NUT![]()

FLARE ADAPTER

![]() PISTON RETAINER

PISTON RETAINER

![]() PISTON

PISTON

LIQUID SERVICE VALVE

A92464

→Fig. 7ÐService Valve with Sweat Adapter Tube

A brazing shield MUST be used when tubing sets are being brazed to the service valves to prevent damage to the painted unit surface.

NOTE: Install branch circuit disconnect per NEC of adequate size to handle unit starting current. Locate disconnect within sight from and readily accessible from unit, per Section

ROUTE GROUND AND POWER WIRES Ð Remove access panel and control box cover to gain access to unit wiring. Extend wires from disconnect through power wiring hole provided and into unit control box. (See Fig. 2.)

CONNECT GROUND AND POWER WIRES Ð Connect ground wire to ground connection in control box for safety. Connect power wiring to contactor as shown in Fig. 8.

CONNECT CONTROL WIRING Ð Route

Use No. 18 AWG

Use furnace transformer, fan coil transformer, or accessory trans- former for control power,

NOTE: Use of available

NOTE: The defrost timer is factory set for

Relieve pressure and recover all refrigerant before system repair or final unit disposal to avoid personal injury or death. Use all service ports and open all

Do not vent refrigerant to atmosphere. Recover during system repair or final unit disposal.

Step 7ÐMake Electrical Connections

To avoid personal injury or death, do not supply power to unit with compressor terminal box cover removed.

DISCONNECT

PER N.E.C. AND/OR LOCAL CODES

FIELD POWER

WIRING

3 PHASE ONLY

FIELD GROUND

WIRING

CONTACTOR

BLUE

GROUND

LUG

Be sure field wiring complies with local and national fire, safety, and electrical codes, and voltage to system is within limits shown on unit rating plate. Contact local power company for correction of improper voltage. See unit rating plate for recommended circuit protection device.

According to NEC, ANSI/NFPA 70, and local codes, the cabinet must have an uninterrupted or unbroken ground to minimize personal injury if an electrical fault should occur. The ground may consist of electrical wire or metal conduit when installed in accordance with existing electrical codes. Failure to follow this warning could result in an electric shock, fire, or death.

NOTE: Operation of unit on improper line voltage constitutes abuse and could affect unit reliability. See unit rating plate. Do not install unit in system where voltage or phase imbalance may fluctuate above or below permissible limits.

NOTE: Use copper wire only between disconnect switch and unit.

A94025

→Fig. 8ÐLine Power Connections

Step 8ÐInstall Electrical Accessories

Refer to the individual instructions packaged with the kits or accessories when installing.

Damage may occur to the scroll compressor if operated at a negative suction pressure during a system pumpdown.

Step 9ÐStart-Up

1.Fully back seat (open) liquid and vapor tube service valves.

2.Unit is shipped with valve stem(s) front seated and caps installed. Replace stem caps after system is opened to refrig- erant flow (back seated). Replace caps finger tight and tighten additional 1/12 turn using a backup wrench on valve body flats to prevent distortion of sheet metal.

3.Close electrical disconnects to energize system.

4.Set room thermostat at desired temperature.

4