Fan wheels are designed to provide low operating costs

The

to the building structure.

The

All motors (single and three phase) are UL listed, factory wired, single speed with thermal overload protec- tion and are continuous duty rated. Motors are supplied with permanently

provided on the top and bottom of each corner of the unit

Durable construction means

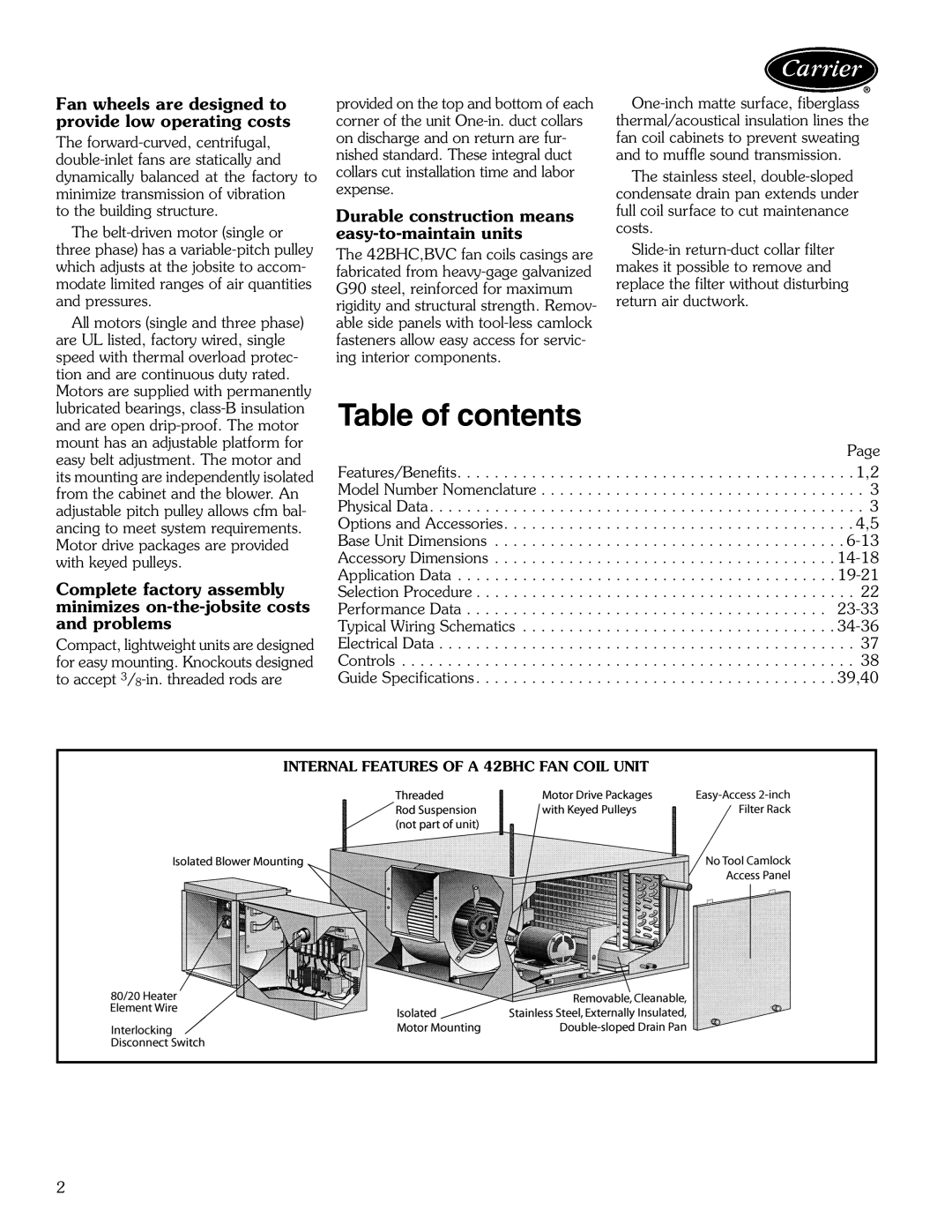

The 42BHC,BVC fan coils casings are fabricated from

The stainless steel,

lubricated bearings,

Complete factory assembly minimizes

Compact, lightweight units are designed for easy mounting. Knockouts designed to accept

Table of contents

Page

Features/Benefits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,2

Model Number Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Physical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Options and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4,5

Base Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessory Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Guide Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39,40

INTERNAL FEATURES OF A 42BHC FAN COIL UNIT

2