Selection procedure

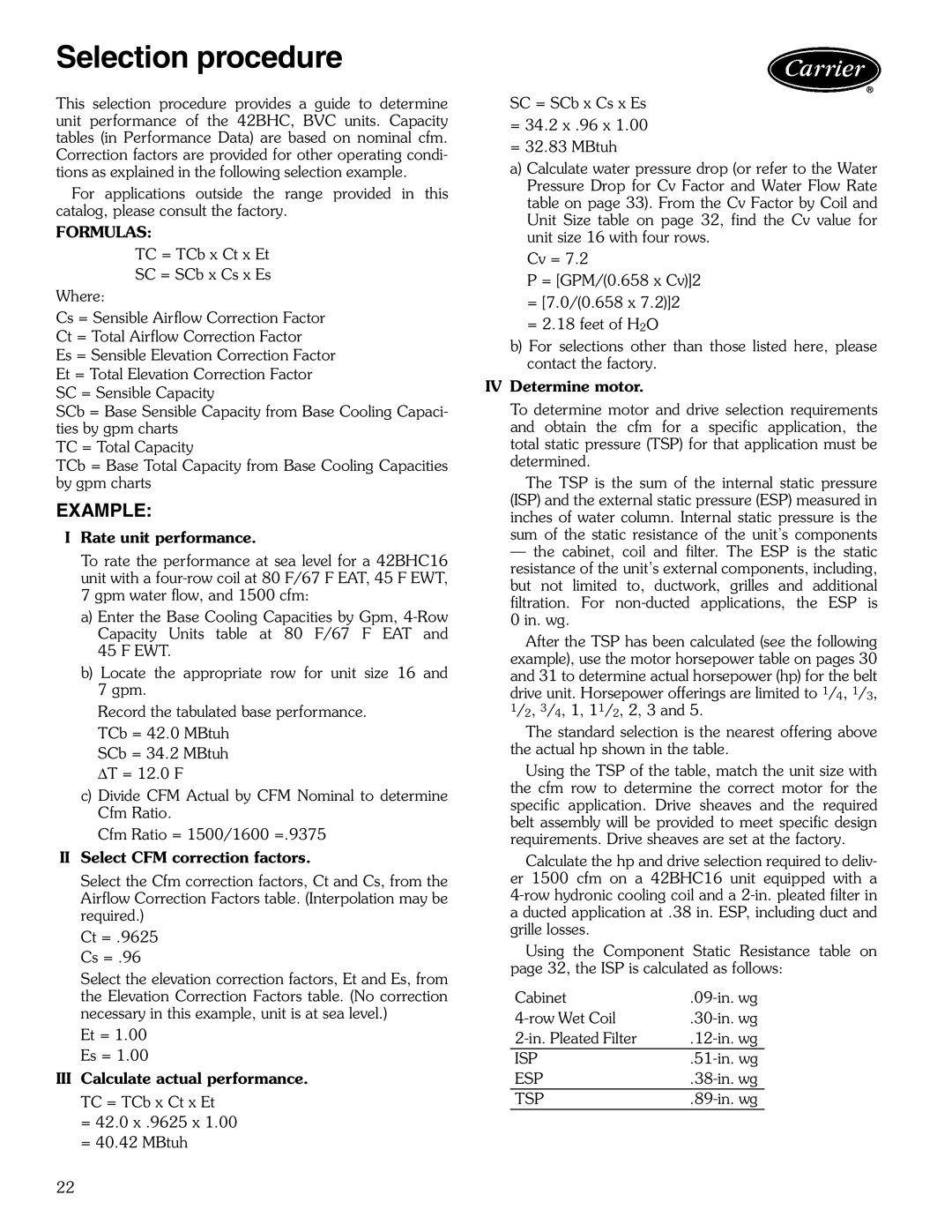

This selection procedure provides a guide to determine unit performance of the 42BHC, BVC units. Capacity tables (in Performance Data) are based on nominal cfm. Correction factors are provided for other operating condi- tions as explained in the following selection example.

For applications outside the range provided in this catalog, please consult the factory.

FORMULAS:

TC = TCb x Ct x Et

SC = SCb x Cs x Es

Where:

Cs = Sensible Airflow Correction Factor Ct = Total Airflow Correction Factor

Es = Sensible Elevation Correction Factor Et = Total Elevation Correction Factor SC = Sensible Capacity

SCb = Base Sensible Capacity from Base Cooling Capaci- ties by gpm charts

TC = Total Capacity

TCb = Base Total Capacity from Base Cooling Capacities by gpm charts

EXAMPLE:

IRate unit performance.

To rate the performance at sea level for a 42BHC16 unit with a

7 gpm water flow, and 1500 cfm:

a)Enter the Base Cooling Capacities by Gpm,

b)Locate the appropriate row for unit size 16 and 7 gpm.

Record the tabulated base performance. TCb = 42.0 MBtuh

SCb = 34.2 MBtuh ∆T = 12.0 F

c)Divide CFM Actual by CFM Nominal to determine Cfm Ratio.

Cfm Ratio = 1500/1600 =.9375

IISelect CFM correction factors.

Select the Cfm correction factors, Ct and Cs, from the Airflow Correction Factors table. (Interpolation may be required.)

Ct = .9625 Cs = .96

Select the elevation correction factors, Et and Es, from the Elevation Correction Factors table. (No correction necessary in this example, unit is at sea level.)

Et = 1.00 Es = 1.00

IIICalculate actual performance. TC = TCb x Ct x Et

=42.0 x .9625 x 1.00

=40.42 MBtuh

SC = SCb x Cs x Es

=34.2 x .96 x 1.00

=32.83 MBtuh

a)Calculate water pressure drop (or refer to the Water Pressure Drop for Cv Factor and Water Flow Rate table on page 33). From the Cv Factor by Coil and Unit Size table on page 32, find the Cv value for unit size 16 with four rows.

Cv = 7.2

P = [GPM/(0.658 x Cv)]2

=[7.0/(0.658 x 7.2)]2

=2.18 feet of H2O

b)For selections other than those listed here, please contact the factory.

IV Determine motor.

To determine motor and drive selection requirements and obtain the cfm for a specific application, the total static pressure (TSP) for that application must be determined.

The TSP is the sum of the internal static pressure (ISP) and the external static pressure (ESP) measured in inches of water column. Internal static pressure is the sum of the static resistance of the unit’s components

—the cabinet, coil and filter. The ESP is the static resistance of the unit’s external components, including, but not limited to, ductwork, grilles and additional

filtration. For

After the TSP has been calculated (see the following example), use the motor horsepower table on pages 30 and 31 to determine actual horsepower (hp) for the belt drive unit. Horsepower offerings are limited to 1/4, 1/3, 1/2, 3/4, 1, 11/2, 2, 3 and 5.

The standard selection is the nearest offering above the actual hp shown in the table.

Using the TSP of the table, match the unit size with the cfm row to determine the correct motor for the specific application. Drive sheaves and the required belt assembly will be provided to meet specific design requirements. Drive sheaves are set at the factory.

Calculate the hp and drive selection required to deliv- er 1500 cfm on a 42BHC16 unit equipped with a

Using the Component Static Resistance table on page 32, the ISP is calculated as follows:

Cabinet | |

ISP | |

ESP | |

TSP |

22