A05075

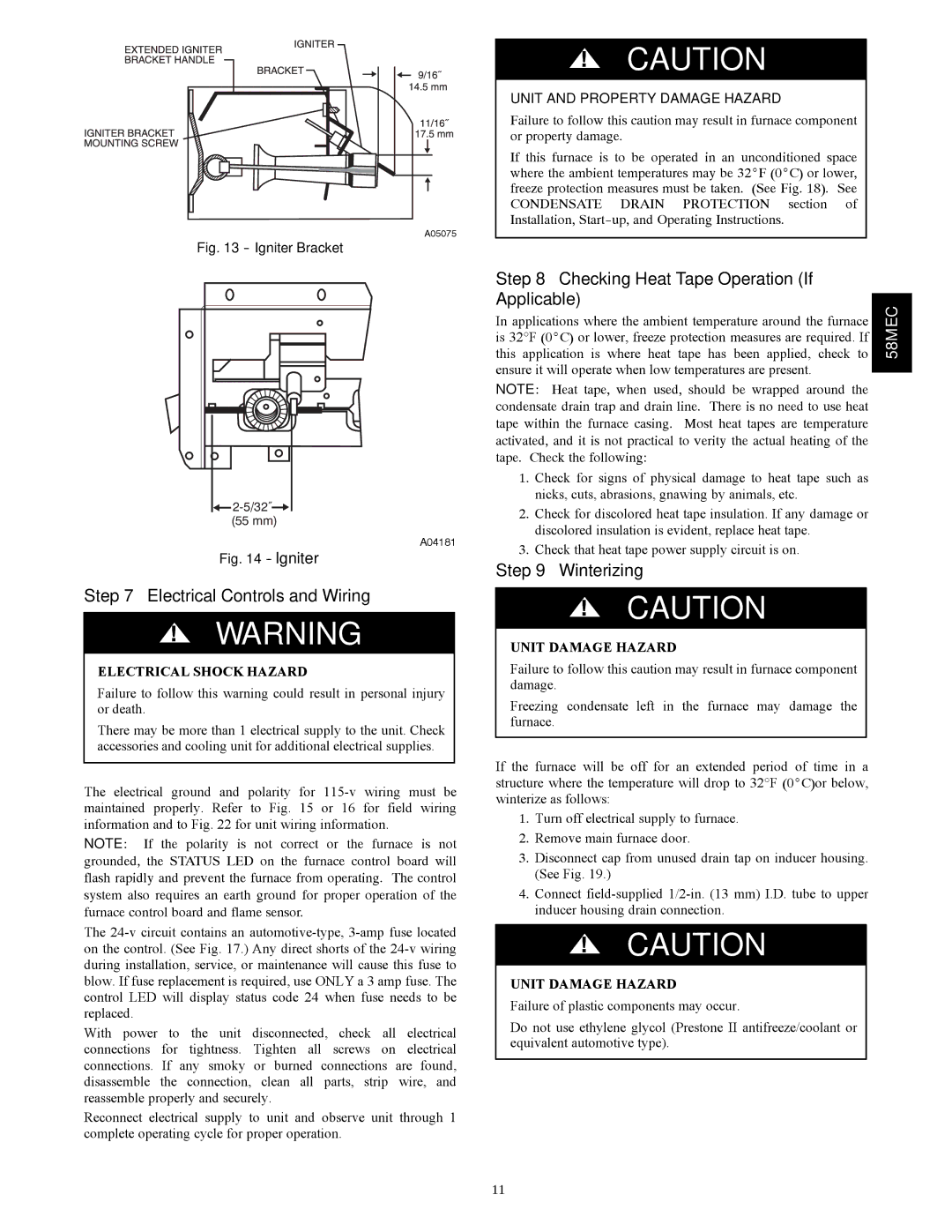

Fig. 13 - Igniter Bracket

(55 mm) |

A04181

Fig. 14 - Igniter

Step 7 — Electrical Controls and Wiring

!WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

There may be more than 1 electrical supply to the unit. Check accessories and cooling unit for additional electrical supplies.

The electrical ground and polarity for

NOTE: If the polarity is not correct or the furnace is not grounded, the STATUS LED on the furnace control board will flash rapidly and prevent the furnace from operating. The control system also requires an earth ground for proper operation of the furnace control board and flame sensor.

The

With power to the unit disconnected, check all electrical connections for tightness. Tighten all screws on electrical connections. If any smoky or burned connections are found, disassemble the connection, clean all parts, strip wire, and reassemble properly and securely.

Reconnect electrical supply to unit and observe unit through 1 complete operating cycle for proper operation.

! | CAUTION |

|

| |

UNIT AND PROPERTY DAMAGE HAZARD |

|

| ||

Failure to follow this caution may result in furnace component |

|

| ||

or property damage. |

|

| ||

If this furnace is to be operated in an unconditioned space |

|

| ||

where the ambient temperatures may be 32_F (0_C) or lower, |

|

| ||

freeze protection measures must be taken. (See Fig. 18). See |

|

| ||

CONDENSATE DRAIN PROTECTION section of |

|

| ||

Installation, |

|

| ||

|

|

| ||

Step 8 — Checking Heat Tape Operation (If |

| |||

Applicable) |

|

|

| |

where heat tape has been applied, check to | 58MEC | |||

this application is | ||||

In applications where the ambient temperature around the furnace |

| |||

is 32°F (0_C) or lower, freeze protection measures are required. If |

| |||

ensure it will operate when low temperatures are present. |

| |||

| ||||

NOTE: Heat tape, when used, should be wrapped around the |

| |||

condensate drain trap and drain line. There is no need to use heat |

| |||

tape within the furnace casing. Most heat tapes are temperature |

| |||

activated, and it is not practical to verity the actual heating of the |

| |||

tape. Check the following: |

| |||

1.Check for signs of physical damage to heat tape such as nicks, cuts, abrasions, gnawing by animals, etc.

2.Check for discolored heat tape insulation. If any damage or discolored insulation is evident, replace heat tape.

3.Check that heat tape power supply circuit is on.

Step 9 — Winterizing

!CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in furnace component damage.

Freezing condensate left in the furnace may damage the furnace.

If the furnace will be off for an extended period of time in a structure where the temperature will drop to 32°F (0_C)or below, winterize as follows:

1.Turn off electrical supply to furnace.

2.Remove main furnace door.

3.Disconnect cap from unused drain tap on inducer housing. (See Fig. 19.)

4.Connect

!CAUTION

UNIT DAMAGE HAZARD

Failure of plastic components may occur.

Do not use ethylene glycol (Prestone II antifreeze/coolant or equivalent automotive type).

11