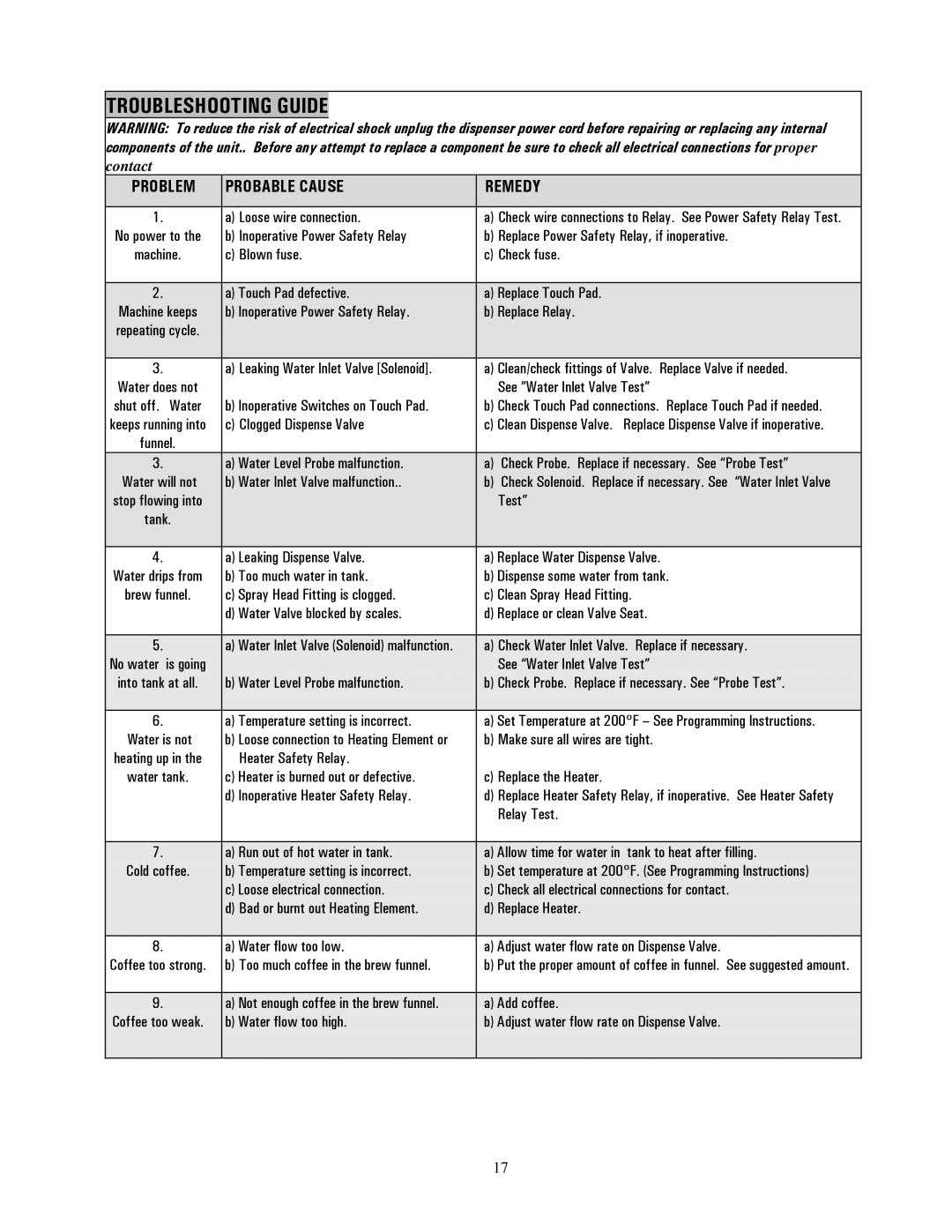

TROUBLESHOOTING GUIDE

WARNING: To reduce the risk of electrical shock unplug the dispenser power cord before repairing or replacing any internal components of the unit.. Before any attempt to replace a component be sure to check all electrical connections for proper contact

PROBLEM | PROBABLE CAUSE | REMEDY |

| ||

|

|

|

| ||

1. |

| a) Loose wire connection. | a) Check wire connections to Relay. See Power Safety Relay Test. | ||

No power to the | b) Inoperative Power Safety Relay | b) Replace Power Safety Relay, if inoperative. | |||

machine. | c) Blown fuse. | c) Check fuse. |

| ||

|

|

|

|

| |

2. |

| a) Touch Pad defective. | a) Replace Touch Pad. |

| |

Machine keeps | b) Inoperative Power Safety Relay. | b) Replace Relay. |

| ||

repeating cycle. |

|

|

|

| |

|

|

|

| ||

3. |

| a) Leaking Water Inlet Valve [Solenoid]. | a) Clean/check fittings of Valve. Replace Valve if needed. | ||

Water does not |

|

| See ”Water Inlet Valve Test” | ||

shut off. | Water | b) Inoperative Switches on Touch Pad. | b) Check Touch Pad connections. Replace Touch Pad if needed. | ||

keeps running into | c) Clogged Dispense Valve | c) Clean Dispense Valve. | Replace Dispense Valve if inoperative. | ||

funnel. |

|

|

|

| |

3. |

| a) Water Level Probe malfunction. | a) | Check Probe. Replace if necessary. See “Probe Test” | |

Water will not | b) Water Inlet Valve malfunction.. | b) | Check Solenoid. Replace if necessary. See “Water Inlet Valve | ||

stop flowing into |

|

| Test” |

| |

tank. |

|

|

|

| |

|

|

|

| ||

4. |

| a) Leaking Dispense Valve. | a) Replace Water Dispense Valve. | ||

Water drips from | b) Too much water in tank. | b) Dispense some water from tank. | |||

brew funnel. | c) Spray Head Fitting is clogged. | c) Clean Spray Head Fitting. | |||

|

| d) Water Valve blocked by scales. | d) Replace or clean Valve Seat. | ||

|

|

|

| ||

5. |

| a) Water Inlet Valve (Solenoid) malfunction. | a) Check Water Inlet Valve. Replace if necessary. | ||

No water | is going |

|

| See “Water Inlet Valve Test” | |

into tank at all. | b) Water Level Probe malfunction. | b) Check Probe. Replace if necessary. See “Probe Test”. | |||

|

|

|

| ||

6. |

| a) Temperature setting is incorrect. | a) Set Temperature at 200°F – See Programming Instructions. | ||

Water is not | b) Loose connection to Heating Element or | b) Make sure all wires are tight. | |||

heating up in the | Heater Safety Relay. |

|

|

| |

water tank. | c) Heater is burned out or defective. | c) Replace the Heater. |

| ||

|

| d) Inoperative Heater Safety Relay. | d) Replace Heater Safety Relay, if inoperative. See Heater Safety | ||

|

|

|

| Relay Test. |

|

|

|

|

|

| |

7. |

| a) Run out of hot water in tank. | a) Allow time for water in | tank to heat after filling. | |

Cold coffee. | b) Temperature setting is incorrect. | b) Set temperature at 200°F. (See Programming Instructions) | |||

|

| c) Loose electrical connection. | c) Check all electrical connections for contact. | ||

|

| d) Bad or burnt out Heating Element. | d) Replace Heater. |

| |

|

|

|

| ||

8. |

| a) Water flow too low. | a) Adjust water flow rate on Dispense Valve. | ||

Coffee too strong. | b) Too much coffee in the brew funnel. | b) Put the proper amount of coffee in funnel. See suggested amount. | |||

|

|

|

|

| |

9. |

| a) Not enough coffee in the brew funnel. | a) Add coffee. |

| |

Coffee too weak. | b) Water flow too high. | b) Adjust water flow rate on Dispense Valve. | |||

|

|

|

|

|

|

17