OPERATION | ||

|

|

|

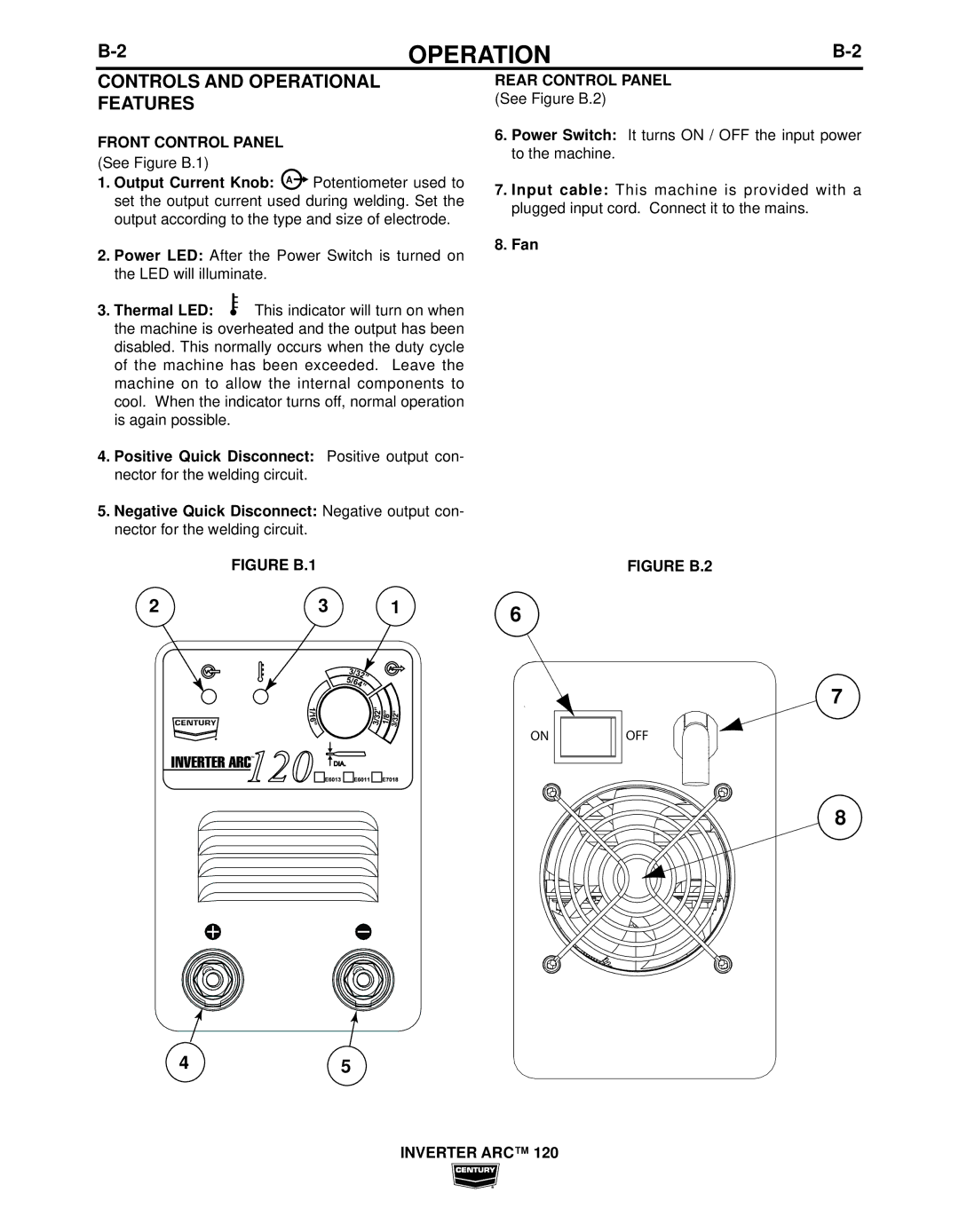

CONTROLS AND OPERATIONAL FEATURES

FRONT CONTROL PANEL

(See Figure B.1)

1. Output Current Knob: A Potentiometer used to set the output current used during welding. Set the output according to the type and size of electrode.

2.Power LED: After the Power Switch is turned on the LED will illuminate.

3. Thermal LED: ![]() This indicator will turn on when the machine is overheated and the output has been disabled. This normally occurs when the duty cycle of the machine has been exceeded. Leave the machine on to allow the internal components to cool. When the indicator turns off, normal operation is again possible.

This indicator will turn on when the machine is overheated and the output has been disabled. This normally occurs when the duty cycle of the machine has been exceeded. Leave the machine on to allow the internal components to cool. When the indicator turns off, normal operation is again possible.

4.Positive Quick Disconnect: Positive output con- nector for the welding circuit.

5.Negative Quick Disconnect: Negative output con- nector for the welding circuit.

FIGURE B.1

2 | 3 | 1 |

45

REAR CONTROL PANEL

(See Figure B.2)

6.Power Switch: It turns ON / OFF the input power to the machine.

7.Input cable: This machine is provided with a plugged input cord. Connect it to the mains.

8.Fan

FIGURE B.2

6

7

ON |

|

|

|

|

|

|

|

| OFF | ||

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8