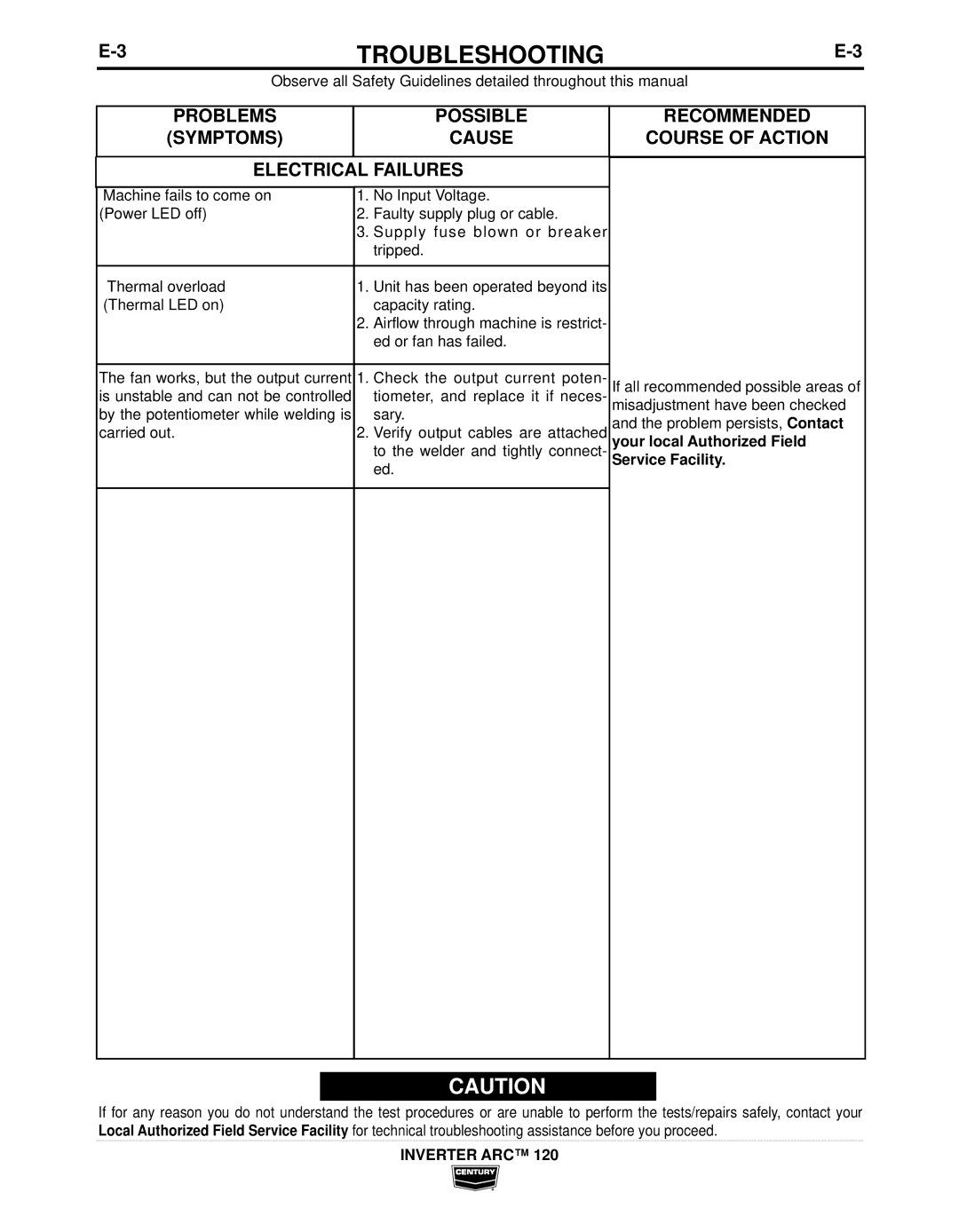

TROUBLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

ELECTRICAL FAILURES

Machine fails to come on | 1. | No Input Voltage. |

(Power LED off) | 2. | Faulty supply plug or cable. |

| 3. Supply fuse blown or breaker | |

|

| tripped. |

|

|

|

Thermal overload | 1. | Unit has been operated beyond its |

(Thermal LED on) |

| capacity rating. |

| 2. | Airflow through machine is restrict- |

|

| ed or fan has failed. |

|

|

|

The fan works, but the output current | 1. | Check the output current poten- |

is unstable and can not be controlled |

| tiometer, and replace it if neces- |

by the potentiometer while welding is |

| sary. |

carried out. | 2. | Verify output cables are attached |

|

| to the welder and tightly connect- |

|

| ed. |

|

|

|

|

|

|

If all recommended possible areas of misadjustment have been checked and the problem persists, Contact your local Authorized Field Service Facility.

![]()

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Authorized Field Service Facility for technical troubleshooting assistance before you proceed.