Cutting head downward travel adjustment (FIG. L)

IA WARNING

To avoid injury from unexpected starting or electrical shock, turn the switch OFF and remove the power cord from the power source.

NOTE: Before each cutting operation, check the position of the blade to make sure it does not contact any metal surface. If the blade contacts any metal surface, the depth of trave! must be adjusted.

1.Lower the blade as far as possible.

2.Loosen the Iocknut (3).

3.Turn the adjustment balt (4) out (counterclockwise) to decrease the cutting depth or in (clockwise) to increase the cutting depth.

4.Rotate the blade manually to check for contacL

5.Repeat until adjusted properly, and tighten the !ocknut to secure the adjustment bolt into position.

4

Fig. L

3

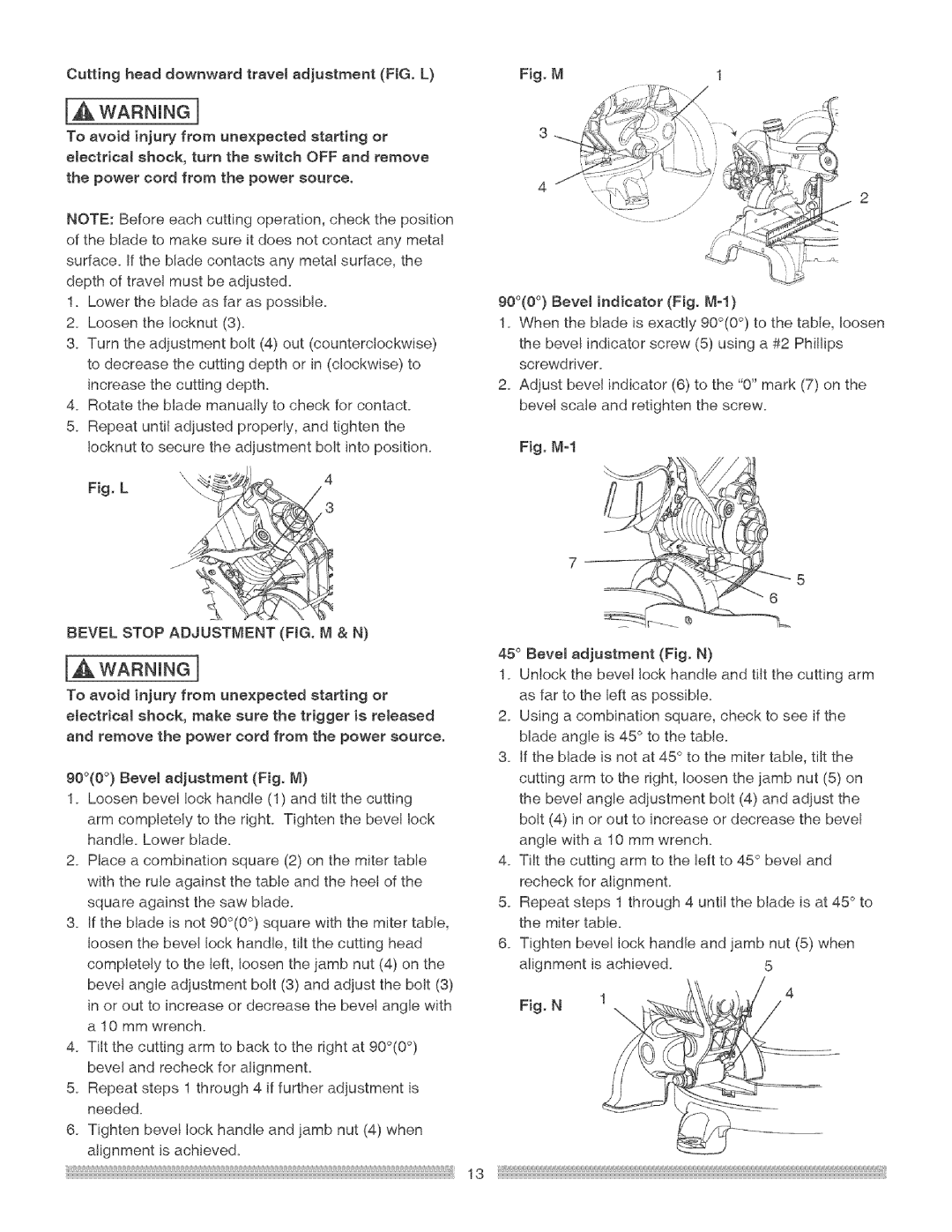

Fig. M

37 2

90°(0 °) Bevel indicator (Fig. M-I )

1.When the blade is exactly 900(0°) to the table, loosen the bevel indicator screw (5) using a #2 Phi!lips screwdriver.

2.Adjust bevel indicator (6) to the "0" mark (7) on the bevel scale and retighten the screw.

Fig. M-l

BEVEL STOP ADJUSTMENT (FIG. M & N)

WARNING

To avoid injury from unexpected starting or electrical shock, make sure the trigger is released and remove the power cord from the power source.

90°(0 °) Bevel adjustment (Fig. M)

1.Loosen bevel lock handle (1) and tilt the cutting arm completely to the right. Tighten the bevel lock handle. Lower blade.

2.Place a combination square (2) on the miter table with the rule against the table and the hee! of the square against the saw blade.

3.If the blade is not 900(0°) square with the miter table, loosen the bevel lock handle, tilt the cutting head completely to the left, loosen the jamb nut (4) on the bevel angle adjustment bait (3) and adjust the bolt (3) in or out to increase or decrease the bevel angle with a 10 mm wrench.

4.Tilt the cutting arm to back to the right at 900(0°) bevel and recheck for alignment.

5.Repeat steps 1 through 4 if further adjustment is needed.

6.Tighten bevel lock handle and jamb nut (4) when alignment is achieved.

45° Bevel adjustment (Fig. N)

1.Unlock the beve! lock handle and tilt the cutting arm as far to the left as possible.

2.Using a combination square, check to see if the blade angle is 45° to the table.

3.If the blade is not at 45 ° to the miter table, tilt the cutting arm to the right, loosen the jamb nut (5) on the bevel angle adjustment bolt (4) and adjust the bolt (4) in or out to increase or decrease the bevel angle with a 10 mm wrench.

4.Tilt the cutting arm to the left to 45° bevel and recheck for alignment.

5.Repeat steps 1 through 4 until the blade is at 45° to the miter table.

6.Tighten bevel lock handle and jamb nut (5) when

alignment is achieved. | 5 |

Fig. N

13