Forbevelingandchamferingoperations,followthesame

procedureasforjointingandplaningdescribedonpages10and

11Beforeperformingtheseoperationsmakesurethesurfaceof.

theworkpiecethatcontactsthefenceisflatandsmooth,Main. lainfirmcontroloftheworkpieceatalttimesholdingit firmly againstfencesurfaceandtablesurfaces.

USING A WET-- DRY VAC

Your

hose connections. Attaching a Craftsman

IF VACUUM HOSE REMAINS PERMANENTLY ATTACH-

,_WARNING:DO NOT REMOVE CHIP DEFLECTOR EVEN ED TO MACHINE. NEVER LEAVE HOSE ON MACHINE

DURING OPERATION IF A VAC IS NOT USED DURING OPERA- TION OR THE HOSE AND MACHINE WILL CLOG WITH CHIPS.

Useholddowntpushblocksforwoodunder3in.widePosition. themsoyouhavecontroloftheworkpieceatalltimesandso theydonotcontacttheguardorthecullerhead.

CHIP EXHAUST-

VACUUM PORT

MAINTENANCE

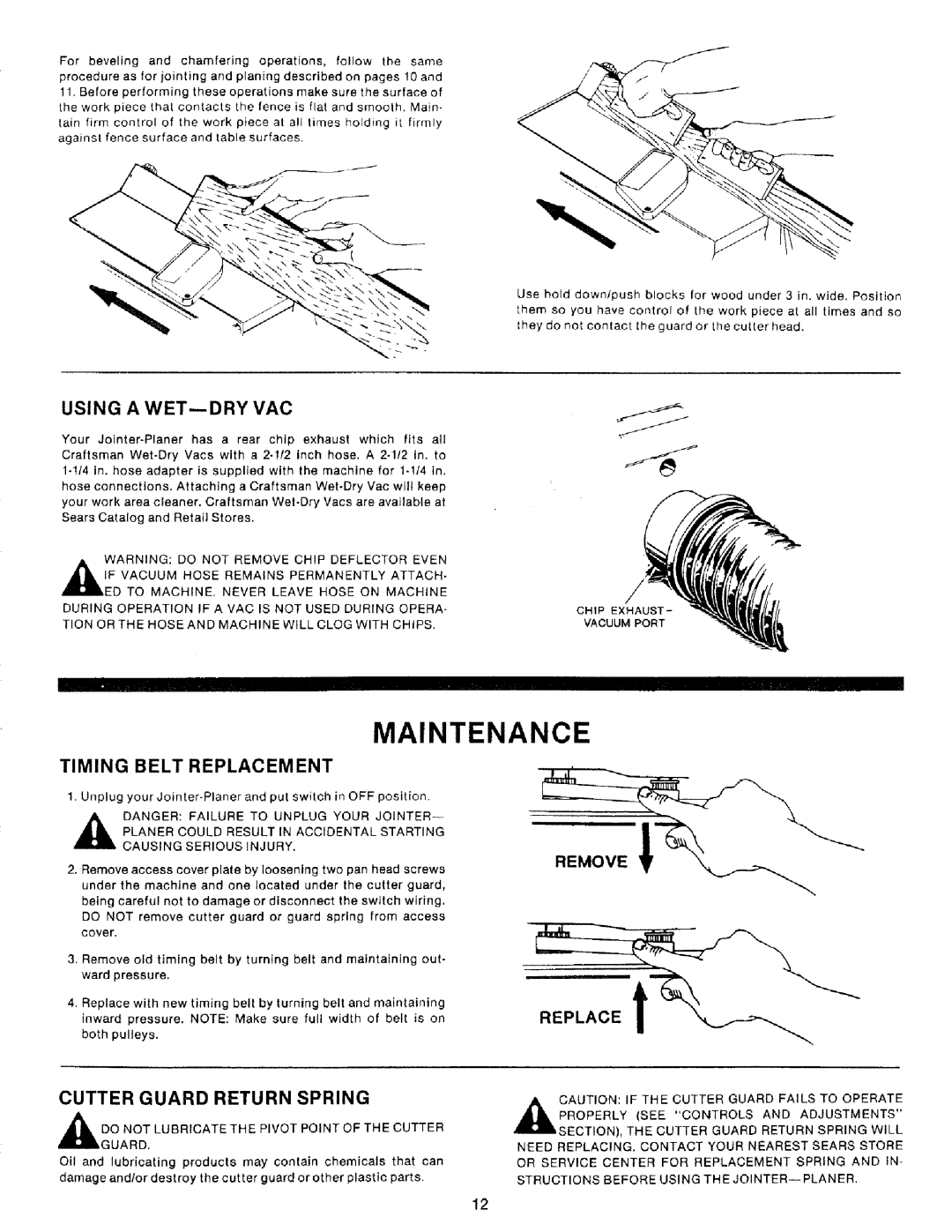

TIMING BELT REPLACEMENT

1. Unplug your

PLANER COULD RESULT IN ACCIDENTAL STARTING

,i_ DANGER: FAILURE TO UNPLUG YOUR

CAUSING SERIOUS INJURY.

2.Remove access cover plate by loosening two pan head screws under the machine and one located under the cutter guard, being careful not to damage or disconnect the switch wiring. DO NOT remove cutter guard or guard spring from access cover.

3.Remove old timing belt by turning belt and maintaining out- ward pressure.

4.Replace with new timing belt by turning belt and maintaining inward pressure. NOTE: Make sure full width of belt is on both pulleys.

CUTTER GUARD RETURN SPRING

,_DO NOT LUBRICATE THE PIVOT POINT OF THE CUTTER GUARD.

Oil and lubricating products may contain chemicals that can damage andtor destroy the cutter guard or other plastic parts.

.EL I

PROPERLY (SEE "CONTROLS AND ADJUSTMENTS"

,_ILCAUTION: IF THE CUTTER GUARD FALLS TO OPERATE SECTION), THE CUTTER GUARD RETURN SPRING WILL

NEED REPLACING. CONTACT YOUR NEAREST SEARS STORE

OR SERVICE CENTER FOR REPLACEMENT SPRING AND iN-

STRUCTIONS BEFORE USING THE

12