INSTALLING THE

If the

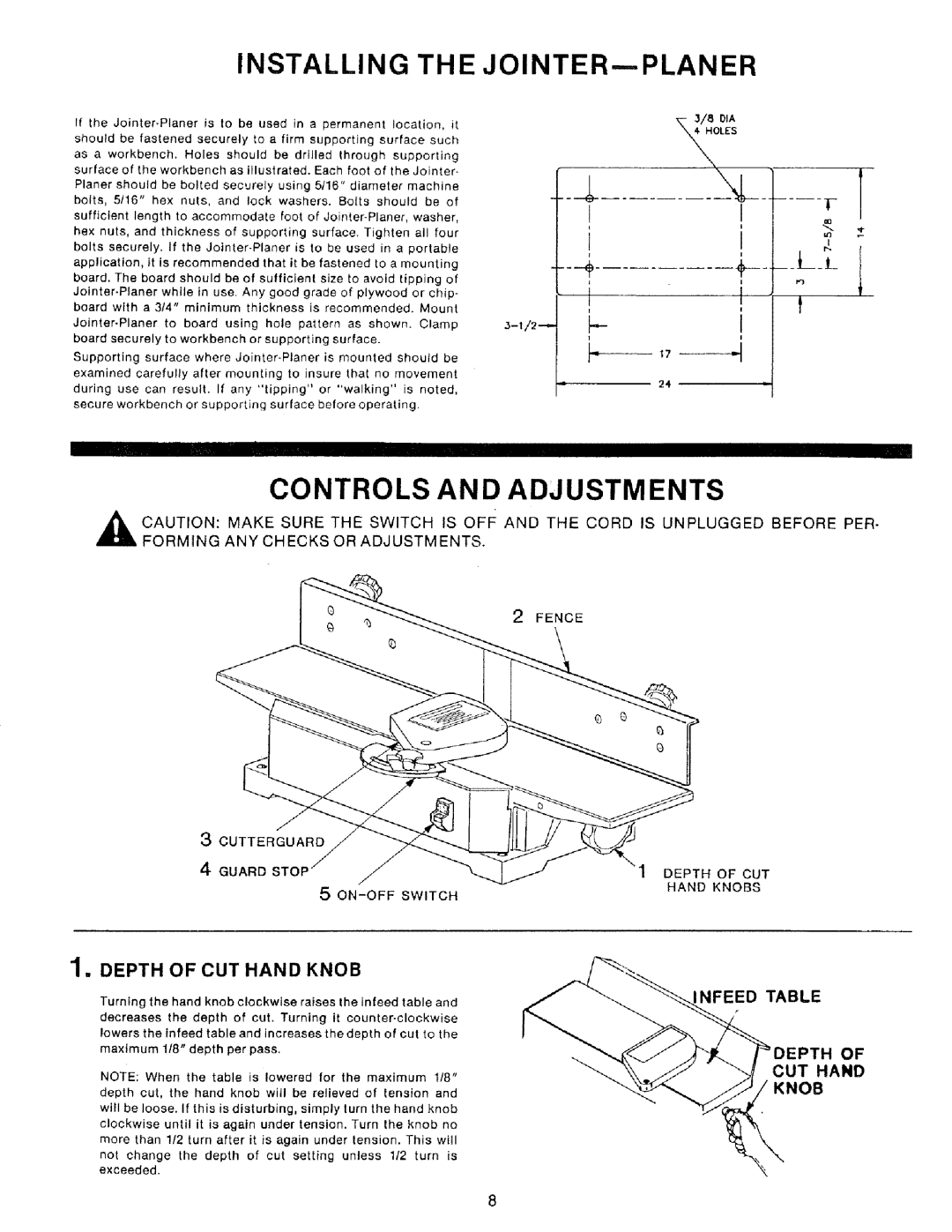

as a workbench. Holes should be drilled through supporting surface of the workbench as illustrated. Each foot of the Jointer- Planer should be bolted securely using 5/16" diameter machine bolts, 5116" hex nuts, and lock washers. Bolts should be of

sufficient length to accommodate foot of

bolts securely. If the

application, it is recommended that it be fastened to a mounting board. The board should be of sufficient size to avoid tipping of

board with a 314" minimum thickness is recommended. Mount

Supporting surface where

during use can result. If any "tipping" or "walking" is noted, secure workbench or supporting surface before operating.

JOINTER--PLANER

_- 3/8 DIA

I!

_LL

J |

|

I | 1 |

i | |

i | |

| 24 |

T

,_ CAUTION: FORMING

I

CONTROLS AND ADJUSTMENTS

THE

MAKE SURE SWITCH IS oFF AND THE CORD IS UNPLUGGED BEFORE PER-

ANY CHECKS OR ADJUSTMENTS.

2FENCE

3 CUTTERGUARD

4 GUARD STOP

5 ON-OFF SWITCH

1. DEPTH OF CUT HAND KNOB

Turning the hand knob clockwise raises the infeed table and decreases the depth of cut. Turning it

NOTE: When the table is lowered for the maximum 118" depth cut, the hand knob will be relieved of tension and will be loose, If this is disturbing, simply turn the hand knob clockwise until it is again under tension. Turn the knob no more than 1/2 turn after it is again under tension. This will

not change the depth of cut setting unless 112 turn is exceeded.

1DEPTH OF CUT HAND KNOBS

NFEED TABLE

OF

CUT HAND

KNOB