METAL CUTTING (Figure 7)

This saw has different metal cuffing capacities depending upon the type of blade being used and metal being cut,

1.ALWAYS clamp the work down to prevent it from slipping.

2.Use a finer blade for ferrous metals and a coarse blade for

3, When cutting thin gauge sheet metals, ALWAYS clamp wood on both sides of the sheet. This will give you a clean cut without excess vibration or tearing of the metal.

4.DO NOT force the cutting blade. Forcing the blade will reduce blade life and cause the blade to break.

NOTE: We recommend that you spread a thin film of oil or other coolant along the line of cut ahead of the saw. This will allow easier operation and help extend blade life.When cuffing aluminum, use kerosene.

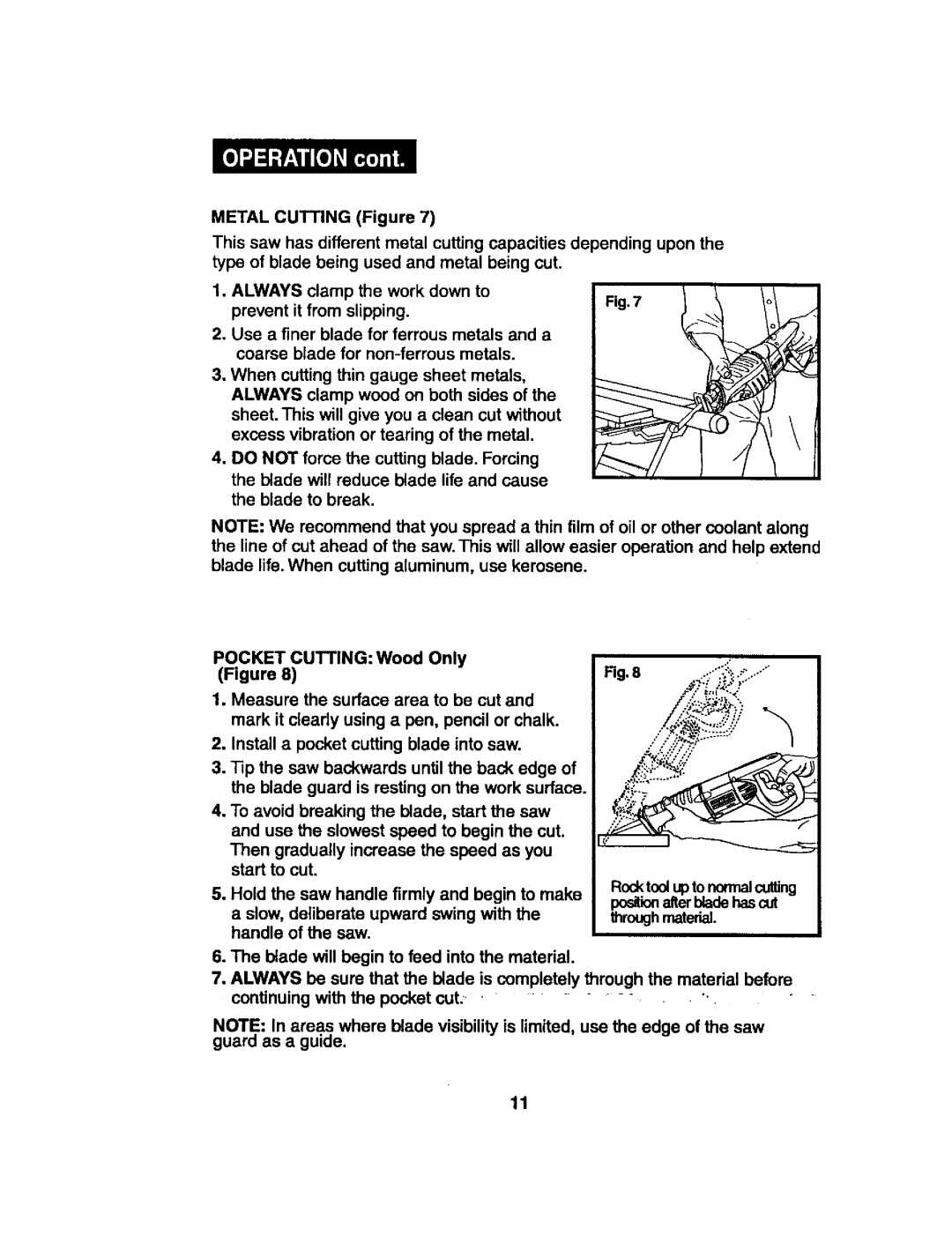

POCKET CUTTING: Wood Only (Figure 8)

1.Measure the surface area to be cut and mark it clearly using a pen, pencil or chalk.

2.Install a pocket cutting blade into saw.

3.Tip the saw backwards until the back edge of the blade guard is resting on the work surface.

4.To avoid breaking the blade, start the saw and use the slowest speed to begin the cut. Then gradually increase the speed as you start to cut.

5.Hold the saw handle firmly and begin to make

a slow, deliberate upward swing with the handle of the saw.

6.The blade will begin to feed into the material.

7.ALWAYS be sure that the blade is completely through the material before

continuing with the pocket | . • "' |

NOTE: In areas where blade visibilityis limited, use the edge of the saw guard as a guide.

11