Throttle Cont_

Choke Lever .... | ___ |

|

| F |

Primer | _ | J | _ I P= Lf_!_l |

Figure 7

6.Standing behind the unit, grasp starter handle and pull rope out until you feel a drag.

7.Pull the rope with a rapid, continuous, full arm stroke. Keep a firm grip on the starter handle. Let the rope rewind slowly.

8.Repeat, if necessary, until engine starts. When engine starts, move throttle/choke lever gradu- ally to START/RUN position.

9.If engine falters, move control lever to CHOKE position, then back to START/RUN position.

10.ALWAYS keep the throttle control in the START/ RUN position when operating the Yard Vacuum.

TO EMPTYBAG

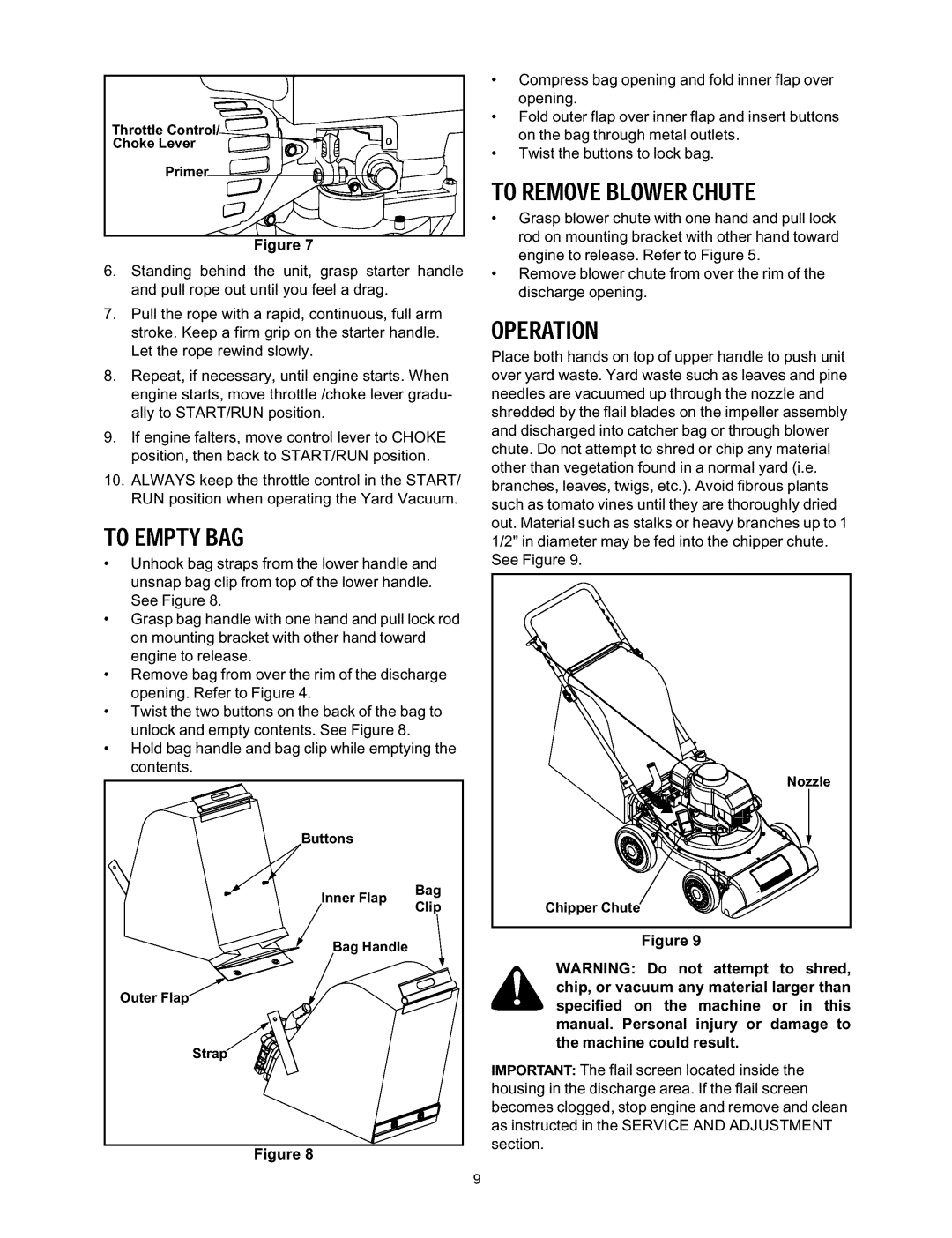

•Unhook bag straps from the lower handle and unsnap bag clip from top of the lower handle. See Figure 8.

•Grasp bag handle with one hand and pull lock rod on mounting bracket with other hand toward engine to release.

•Remove bag from over the rim of the discharge opening. Refer to Figure 4.

•Twist the two buttons on the back of the bag to unlock and empty contents. See Figure 8.

•Hold bag handle and bag clip while emptying the contents.

Inner Flap Bag

Cli

Bag Handle

Stra

Figure 8

•Compress bag opening and fold inner flap over opening.

•Fold outer flap over inner flap and insert buttons on the bag through metal outlets.

•Twist the buttons to lock bag.

TO REMOVEBLOWERCHUTE

•Grasp blower chute with one hand and pull lock rod on mounting bracket with other hand toward engine to release. Refer to Figure 5.

•Remove blower chute from over the rim of the discharge opening.

OPERATION

Place both hands on top of upper handle to push unit over yard waste. Yard waste such as leaves and pine needles are vacuumed up through the nozzle and shredded by the flail blades on the impeller assembly and discharged into catcher bag or through blower chute. Do not attempt to shred or chip any material other than vegetation found in a normal yard (i.e. branches, leaves, twigs, etc.). Avoid fibrous plants such as tomato vines until they are thoroughly dried out. Material such as stalks or heavy branches up to 1 1/2" in diameter may be fed into the chipper chute. See Figure 9.

Nozzle

Chi

Figure 9

chip, or vacuum any material larger than

WARNING: Do not attempt to shred,

specified on the machine or in this

manual. Personal injury or damage to the machine could result.

IMPORTANT:The flail screen located inside the

housing in the discharge area. If the flail screen becomes clogged, stop engine and remove and clean as instructed in the SERVICE AND ADJUSTMENT section.