adjustment to the unit without first

WARNING: Do not at any time make any

stopping engine and disconnecting

spark plug wire.

NOZZLEHEIGHTADJUSTMENT

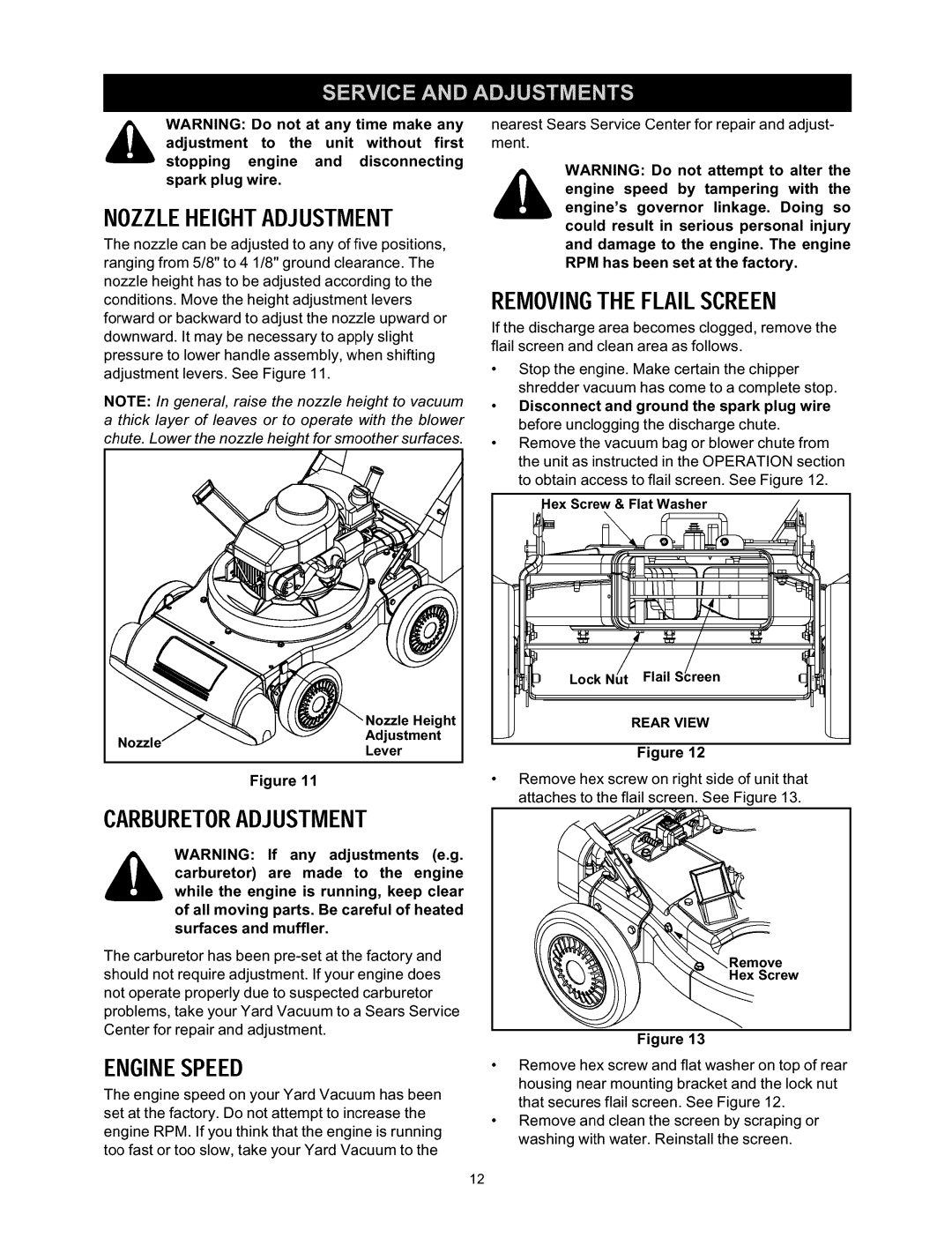

The nozzle can be adjusted to any of five positions, ranging from 5/8" to 4 1/8" ground clearance. The nozzle height has to be adjusted according to the conditions. Move the height adjustment levers forward or backward to adjust the nozzle upward or downward. It may be necessary to apply slight pressure to lower handle assembly, when shifting adjustment levers. See Figure 11.

NOTE: In general, raise the nozzle height to vacuum a thick layer of leaves or to operate with the blower chute. Lower the nozzle height for smoother surfaces.

Height

Adjustment

Lever

Figure 11

CARBURETORADJUSTMENT

carburetor) are made to the engine WARNING: If any adjustments (e.g. while the engine is running, keep clear

of all moving parts. Be careful of heated surfaces and muffler.

The carburetor has been

ENGINESPEED

The engine speed on your Yard Vacuum has been set at the factory. Do not attempt to increase the engine RPM. If you think that the engine is running too fast or too slow, take your Yard Vacuum to the

nearest Sears Service Center for repair and adjust- ment.

WARNING: Do not attempt to alter the

engine speed by tampering with the

engine's governor linkage. Doing so could result in serious personal injury and damage to the engine. The engine RPM has been set at the factory.

REMOVINGTHE FLAILSCREEN

If the discharge area becomes clogged, remove the flail screen and clean area as follows.

•Stop the engine. Make certain the chipper shredder vacuum has come to a complete stop.

•Disconnect and ground the spark plug wire before unclogging the discharge chute.

•Remove the vacuum bag or blower chute from the unit as instructed in the OPERATION section to obtain access to flail screen. See Figure 12.

REAR VIEW

Figure 12

Remove hex screw on right side of unitthat attaches to the flail screen. See Figure 13.

Remove

Hex Screw

Figure 13

•Remove hex screw and flat washer on top of rear housing near mounting bracket and the lock nut that secures flail screen. See Figure 12.

•Remove and clean the screen by scraping or washing with water. Reinstall the screen.

12