•When sharpening the blade, follow the original angle of grind as a guide. It is extremely important that each cutting edge receives an equal amount of

grinding to prevent an unbalanced blade. An unbal- anced blade will cause excessive vibration when

rotating at high speeds and may cause damage to the unit.

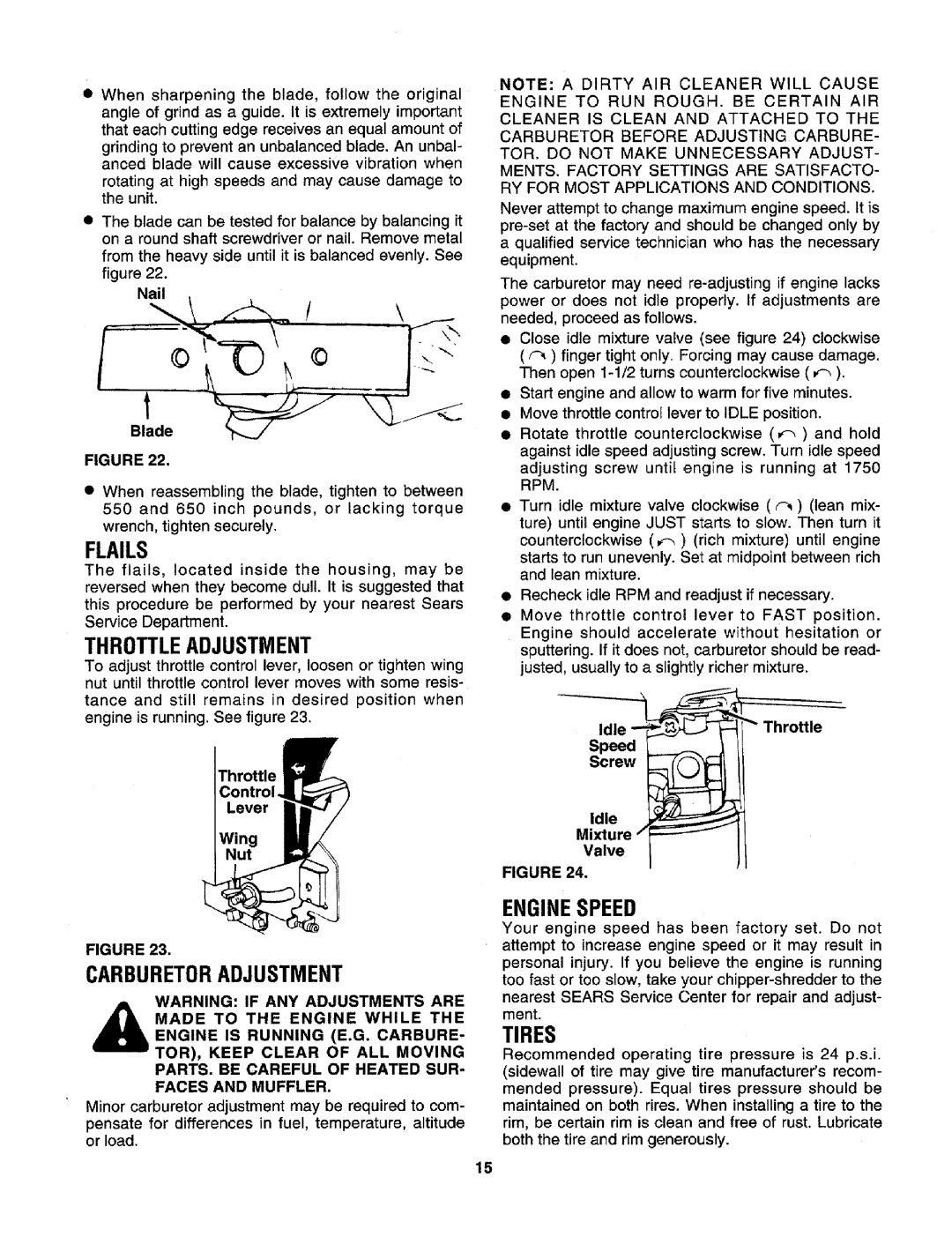

•The blade can be tested for balance by balancing it on a round shaft screwdriver or nail. Remove metal

from the heavy side until it is balanced evenly. See

figure 22.

Nail

! \

/°

Blade

FIGURE 22.

•When reassembling the blade, tighten to between 550 and 650 inch pounds, or lacking torque

wrench, tighten securely.

FLAILS

The flails, located inside the housing, may be reversed when they become dull. It is suggested that this procedure be performed by your nearest Sears Service Department.

THROTTLEADJUSTMENT

To adjust throttle control lever, loosen or tighten wing nut until throttle control lever moves with some resis-

tance and still remains in desired position when engine is running. See figure 23.

Throttle

Control.

Lever

Wing

Nut

FIGURE 23.

CARBURETORADJUSTMENT

WARNING: IF ANY ADJUSTMENTS ARE

_IL MADEENGINE TOIS THERUNNINGENGINE(E.G.WHILECARBURETHE-

TOR), KEEP CLEAR OF ALL MOVING PARTS. BE CAREFUL OF HEATED SUR-

FACES AND MUFFLER.

Minor carburetor adjustment may be required to com- pensate for differences in fuel, temperature, altitude or load.

NOTE: A DIRTY AIR CLEANER WILL CAUSE ENGINE TO RUN ROUGH. BE CERTAIN AIR CLEANER IS CLEAN AND ATTACHED TO THE CARBURETOR BEFORE ADJUSTING CARBURE- TOR. DO NOT MAKE UNNECESSARY ADJUST- MENTS. FACTORY SETTINGS ARE SATISFACTO- RY FOR MOST APPLICATIONS AND CONDITIONS.

Never attempt to change maximum engine speed. It is

The carburetor may need

•Close idle mixture valve (see figure 24) clockwise ( f'_ ) finger tight only. Forcing may cause damage. Then open

•Start engine and allow to warm for five minutes.

•Move throttle control lever to IDLE position.

•Rotate throttle counterclockwise (,,_) and hold against idle speed adjusting screw. Turn idle speed

adjusting screw until engine is running at 1750 RPM.

•Turn idle mixture valve clockwise

•Recheck idle RPM and readjust if necessary.

•Move throttle control lever to FAST position. Engine should accelerate without hesitation or sputtering. If it does not, carburetor should be read- justed, usually to a slightly richer mixture.

Throttle

Speed

Screw

Idle

Mixture

Valve

FIGURE 24.

ENGINESPEED

Your engine speed has been factory set. Do not attempt to increase engine speed or it may result in personal injury. If you believe the engine is running too fast or too slow, take your

TIRES

Recommended operating tire pressure is 24 p.s.i. (sidewall of tire may give tire manufacturer's recom- mended pressure). Equal tires pressure should be maintained on both rires. When installing a tire to the rim, be certain rim is clean and free of rust. Lubricate both the tire and rim generously.

15