_i WARNING: Your sander/polishershould never be connected to power supplywhen you are

assembling parts, making adjustments, assembling or replacing sanding discs or bonnets, cleaning, or when not in use, Disconnecting sander/polisher will prevent accidental starting that could cause serious personal injury.

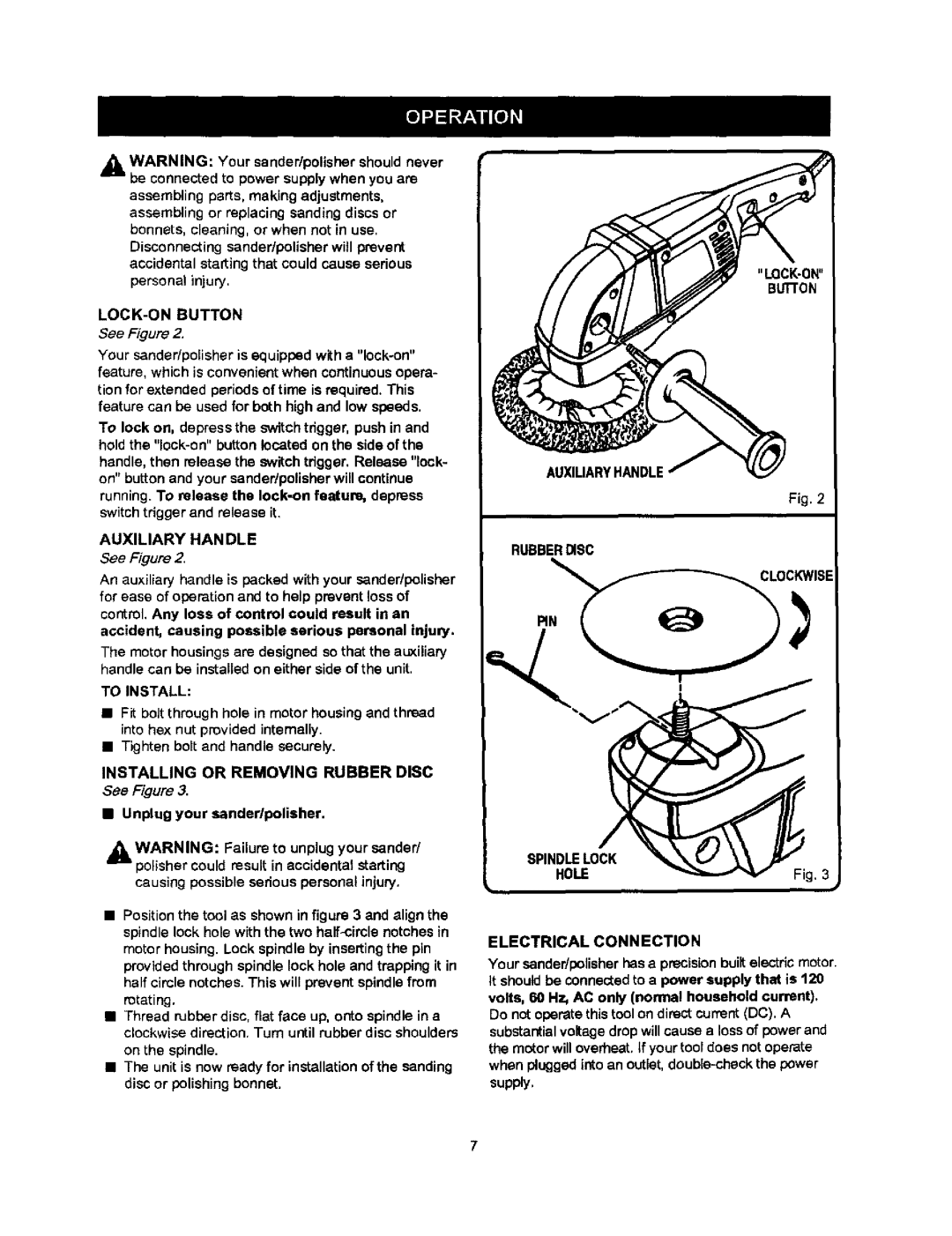

LOCK-ON BUTTON

See Figure 2.

Your sander/polisher is equipped with a

To lock or=, depress the switch tdgger, push in and hold the

handle, then release the switch tdgger, Release "lock- on" button and your sander/polisher will continue

running. To release the Iock,.on feature, depress switch trigger and release it.

AUXILIARY HAN DLE

See Figure 2.

An auxiliary handle is pocked with your sander/polisher for ease of operation and to help prevent loss of control.Any loss of control could result in an

accident, causing possible serious personal injury.

The motor housingsare designed so that the aL_iliary handle can be installed on either side of the unit,

TO INSTALL:

•Fit bolt through hole in motor housing and thread into hex nut provided internally.

•Tighten bolt and handle securely.

INSTALLING OR REMOVING RUBBER DISC

See Figure 3,

•Unplug your sander/polisher.

,_ WARN IN G: Failure to unplug your sander/ polisher could result in accidental starting

causing possible sedous personal injury.

•Position the tool as shown in figure 3 and align the spindle lock hole with the two

•Thread rubber disc, flat face up, onto spindle in a clockwise direction. Turn until rubber disc shoulders

on the spindle.

•The unit is now ready for installation of the sanding disc or polishing bonnet.

RUBBER_$C

CLOCKWISE

ELECTRICAL CONNECTION

Your sandedpelisher has a precision built electric motor. It should be connected to a power supply that is 120 volts. 60 Hz_ AC only (normal household current), Do not operate this tool on direct current (DC). A substantial voltage drop will cause a loss of power and the motor will overheat. If your tool does not operate when plugged into an outlet,

supply,

7