PREPARINGFOROPERATION

For ease of operation, this tool has a front aL_iliary handle and mar handle. See Ffgure 1. This provides for

SANDING

Clamp or otherwise secure the work to prevent it from moving under your sander/polisher, Secure small

workpieces in a vise or use clamps to secure them to a workbench.

_, WARNING: Unsecured work could be thrown towards the operator causing injury.

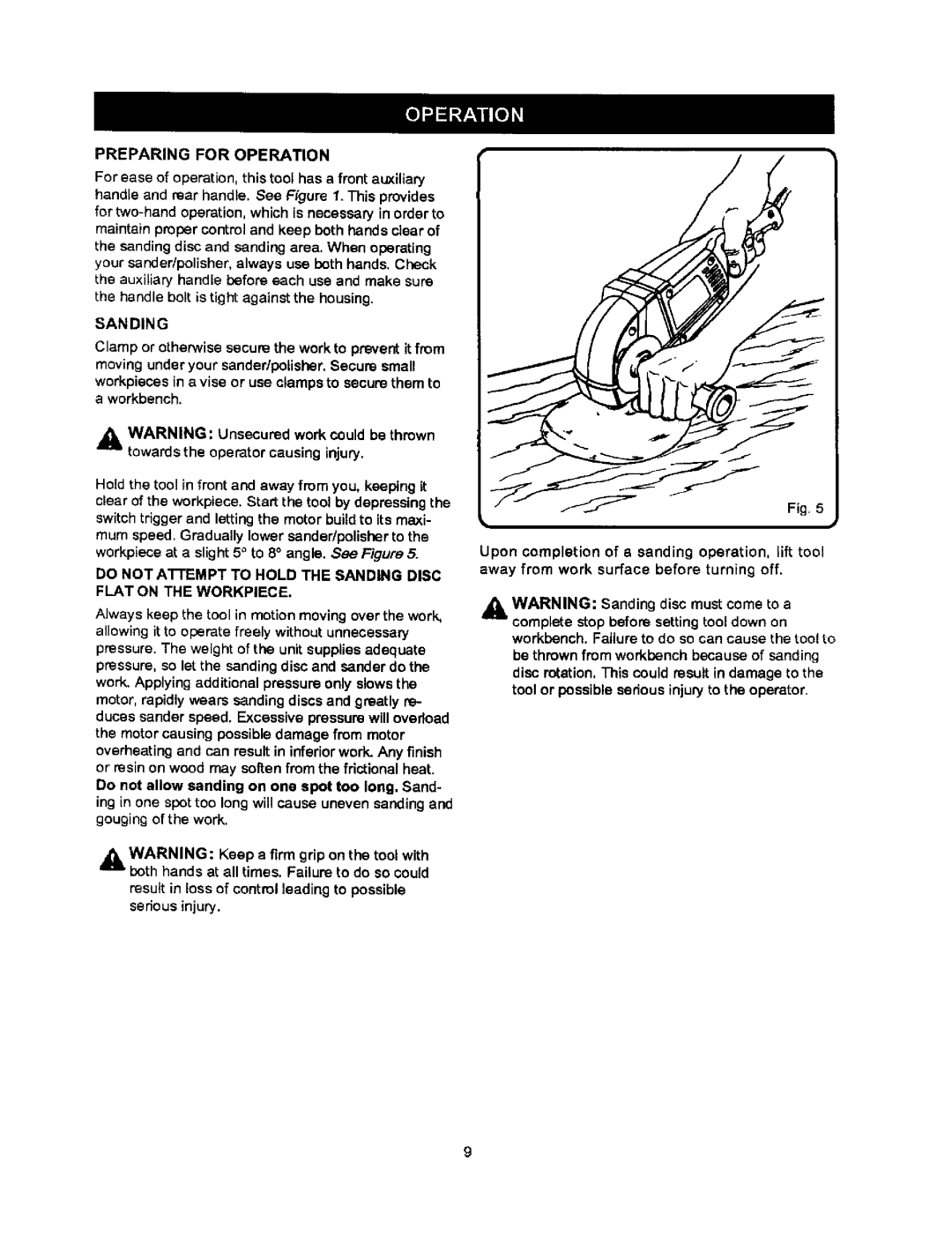

Hold the tool in front and away from you, keeping it clear of the workpiece. Start the tool by depressing the switch trigger and letting the motor build to its maxi- mum speed. Gradually lower sander/polisher to the workpiece at a slight 5° to 8° angle. See Figure 5.

DO NOT A'n'EMPT TO HOLD THE SANDING DISC FLAT ON THE WORKPIECE.

Always keep the tool in motion moving over the work, allowing it to operate freely without unnecessary pressure. The weight of the unit supplies adequate pressure, so let the sanding disc and sander do the work. Applying additional pressure only slows the motor, rapidly wears sanding discs and greatly re- duces sander speed. Excessive pressure will ovedoad the motor causing possible damage from motor overheating and can result in inferior work. Any finish or resin on wood may soften from the frictional heat.

Do not allow sanding on one spot too long. Sand-

ing in one spot too long will cause uneven sanding and gouging of the work.

_.WARNING: Keep a firm grip on the tool with both hands at all times. Failure to do so could

result in loss of controlleading to possible sedous injury.

Upon completion of a sanding operation, lift tool

away from work surface before turning off.

_I, WARNING: Sanding disc must come to a complete stop before setting tool down on workbench. Failure to do so can cause the tool to

be thrown from workbench because of sanding disc ro_ation, This could result in damage to the tool or possible sedous injury to the operator.