Whencuttingcrownmolding by this method the bevel angle should be sot at 33.85 °. The miter angle should be sot at 31.62 ° either right or left, depending on the desired cut for the application. See the chart below for correct angle settings and correct positioning of crown molding on miter table.

The settings in the chart below can be used for cutting

All Standard (U.S.) crown molding with 52 ° and 38 ° angles. The crown molding is placed flat on the miter table using the compound features of your miter saw.

Bevel

AngleType of Cut

Settlng

33.85 =

Left slde, Inslde corner

I. Top edge of molding against fence

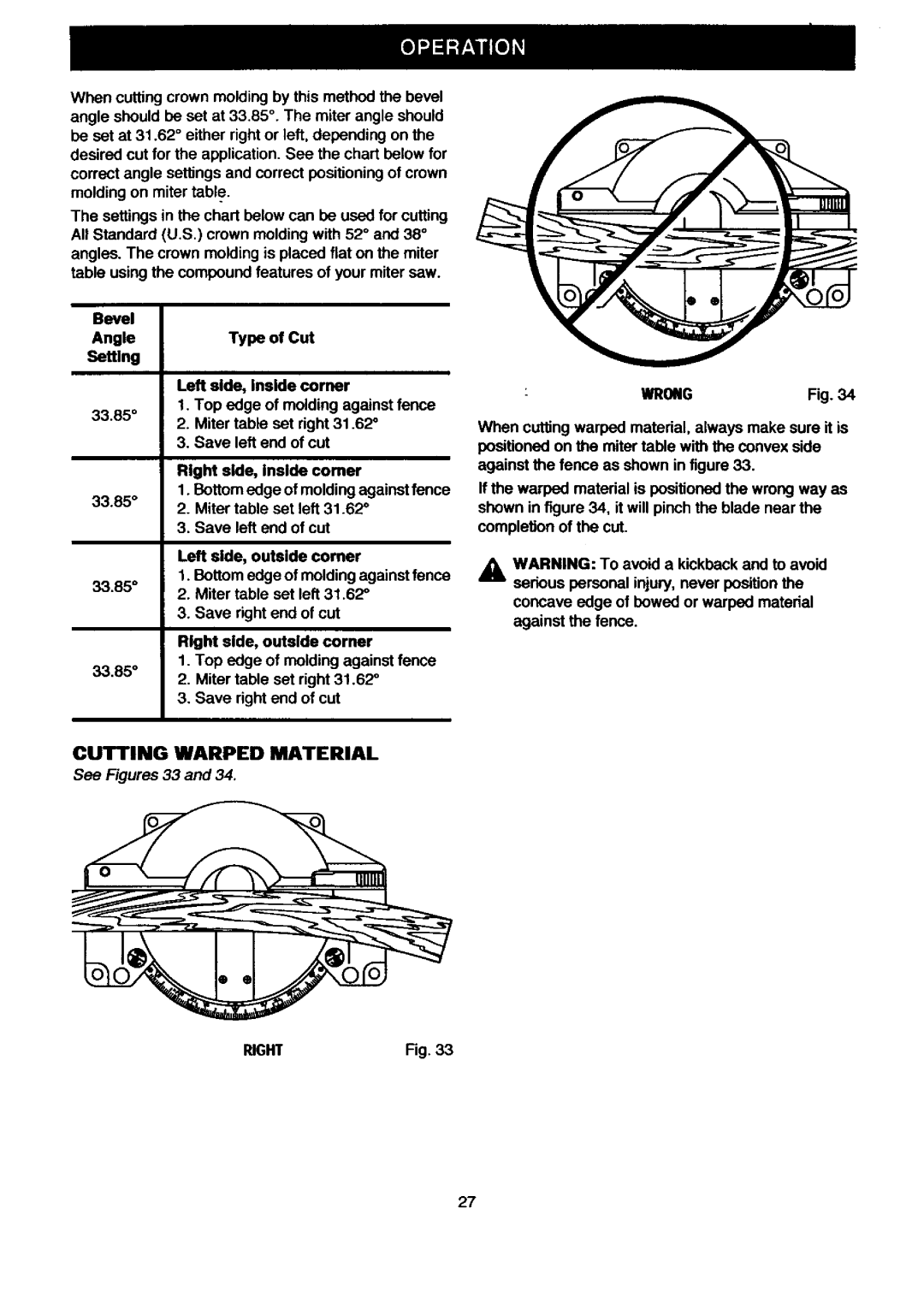

WRONG | Fig. 34 |

2.Miter table sot right 31.62 =

3.Save left end of cut

Right side, Inside comer

1.Bottom edge of molding against fence

33"85° 2. Miter table set left 31.62 =

3. Save left end of cut

Left side, outside comer

1.Bottom edge of molding against fence

33"85= 2. Miter table sot left 31.62 °

3. Save right end of cut

Right side, outside corner

1.Top edge of molding against fence

33"85° 2. Miter table set right 31.62 °

3. Save right end of cut

CUTTING WARPED MATERIAL

See Figures 33 and 34.

When cuffing warped material, always make sure it is positioned on the miter table with the convex side against the fence as shown in figure 33.

If the warped material is positioned the wrong way as shown in figure 34, it will pinch the blade near the completion of the cut.

WARNING: To avoid a kickback and to avoid serious personal injury, never position the

concave edge of bowed or warped material against the fence.

RIGHT | Fig. 33 |

27