POSITIVE STOPS ON MITER TABLE

Positive stops have been provided at 0°,

31.6°, and 45°. The

BEVEL LOCK KNOB

The bevel lock knob securely locks your compound miter saw at desired bevel angles. Positive stop adjustment screws have been provided on each side of the saw arm. These adjustment screws are for

making fine adjustments at 0 ° and 45 °. See pages 17 and 18.

.ELECTRIC BRAKE

An electric brake has been provided to quickly stop blade rotation after the switch is released.

FENCE

The fence on your compound miter sew has been provided to hold your workpiece securely against

when making all cuts.

SELF-RETRACTING LOWER BLADE

GUARD

The lower blade guard is made of

guard as the saw is lowered into the workpiece.

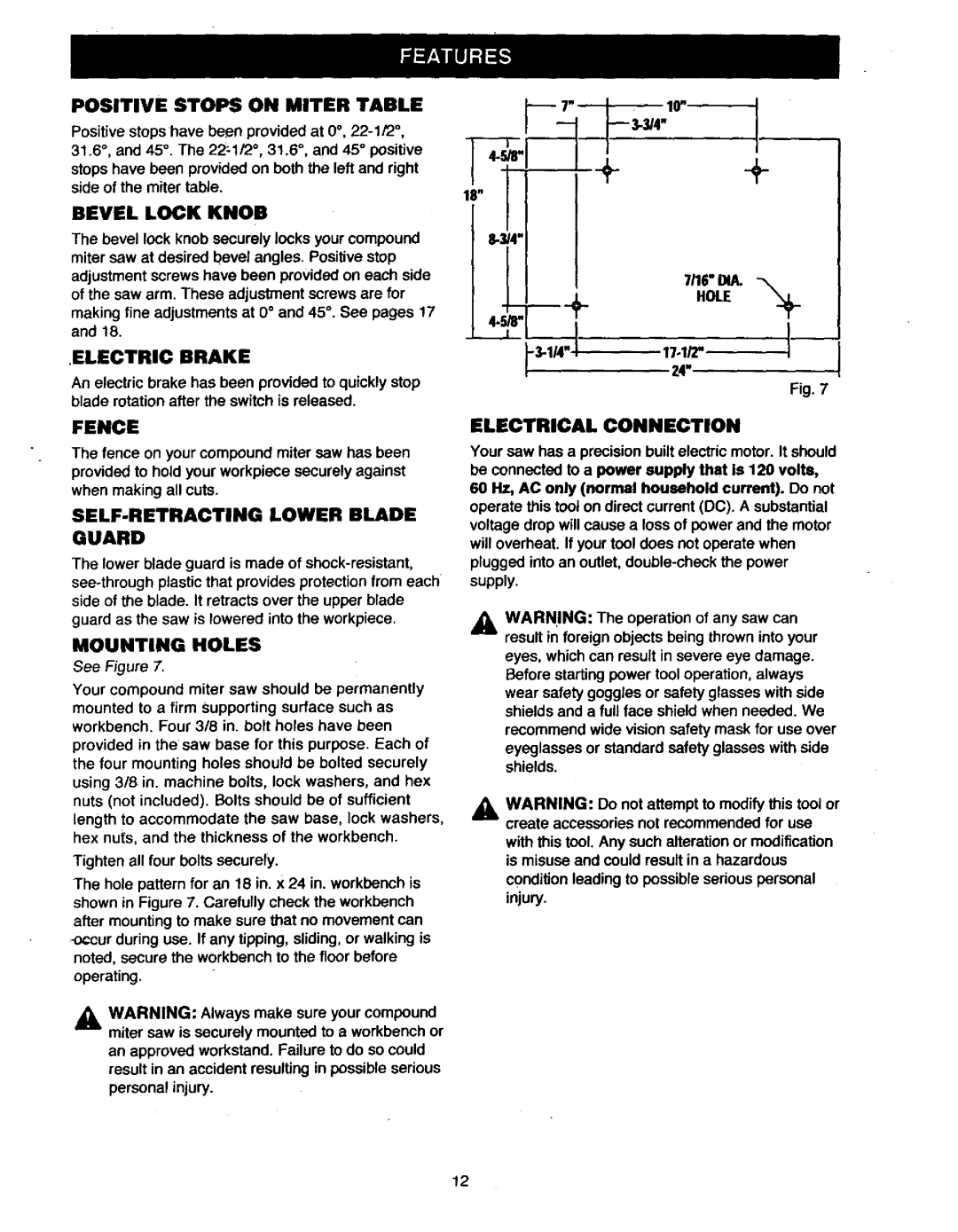

MOUNTING HOLES

See Figure 7.

Your compound miter saw should be permanently mounted to a firm Supporting surface such as workbench. Four 3/8 in. bolt holes have been provided in the saw base for this purpose. Each of the four mounting holes should be bolted securely using 318 in. machine bolts, lock washers, and hex nuts (not included). Bolts should be of sufficient length to accommodate the saw base, lock washers, hex nuts, and the thickness of the workbench.

Tighten all four bolts securely.

The hole pattern for an 18 in. x 24 in. workbench is shown in Figure 7. Carefully check the workbench after mounting to make sure that no movement can

_, WARNING: Always make sure your compound miter saw is securely mounted to a workbench or an approved workstand. Failure to do so could result in an accident resulting in possible serious personal injury.

Fig. 7

ELECTRICAL CONNECTION

Your saw has a precision built electric motor. It should be connected to a power supply that is 120 volts,

60 Hz, AC only (normal household current). Do not operate this tool on direct current (DC). A substantial voltage drop will cause a loss of power and the motor will overheat. If your tool does not operate when plugged into an outlet,

supply.

_h WARNING: The operation of any saw can result in foreign objects being thrown into your

eyes, which can result in severe eye damage. Before starting power tool operation, always

wear safety goggles or safety glasses with side shields and a full face shield when needed. We

recommend wide vision safety mask for use over eyeglasses or standard safety glasses with side shields.

_k WARNING: Do not attempt to modify this tool or create accessories not recommended for use

with this tool. Any such alteration or modification is misuse and could result in a hazardous condition leading to possible serious personal injury.

12