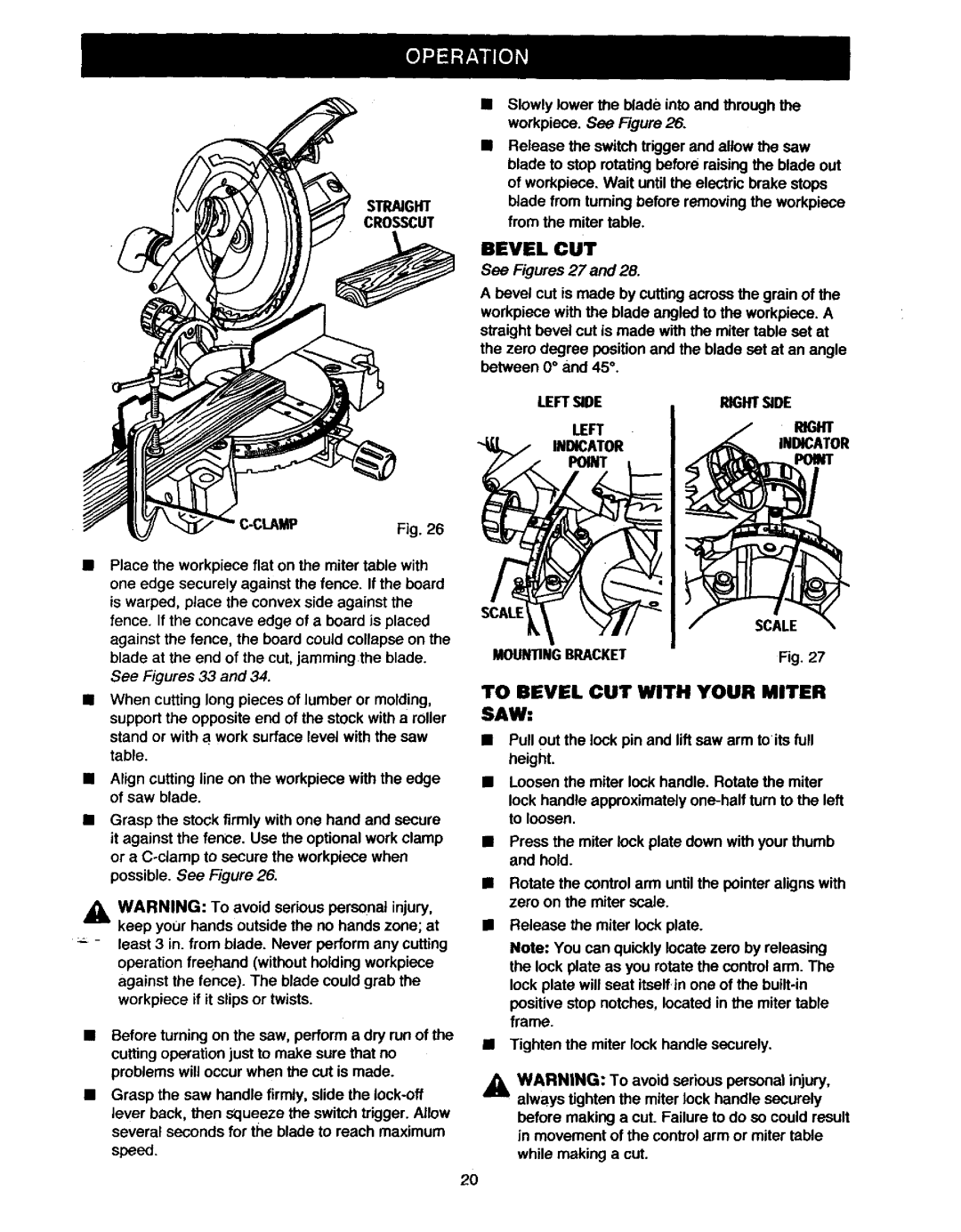

STRAIGHT

CROSSCUT

Fig. 26

Place the workpiece flat on the miter table with one edge securely against the fence. If the board is warped, place the convex side against the fence. If the concave edge of a board is placed against the fence, the hoard could collapse on the blade at the end of the cut, jamming the blade. See Figures 33 and 34.

When cutting long pieces of lumber or molding, support the opposite end of the stock with a roller stand or with a work surface level with the saw table.

Align cutting line on the workpiece with the edge of saw blade.

Grasp the stock firmly with one hand and secure it against the fence. Use the optional work clamp or a

WARNING: To avoid serious personal injury, keep your hands outside the no hands zone; at

_- - least 3 in. from blade. Never perform any cutting operation freehand (without holding workpiece against the fence). The blade could grab the workpiece if it slips or twists.

•Before turning on the saw, perform a dry run of the cutting operation just to make sure that no problems will occur when the cut is made.

•Grasp the saw handle firmly, slide the

Slowly lower the blade into and through the workpiece. See Figure 26.

Release the switch trigger and allow the saw blade to stop rotating before raising the blade out of workpiece, Wait until the electric brake stops blade from turning before removing the workpiece from the miter table.

BEVEL CUT

See Figures 27 and 28.

A bevel cut is made by cutting across the grain of the

workpiece with the blade angled to the workpieca. A

straight bevel out is made with the miter table set at

the zero degree position and the blade set at an angle between 0° and 45 °.

LEFTSiDE | RIGHTSIDE |

LEFT | RIGHT |

INDICATOR | INDICATOR |

POINT | POINT |

SCALE

SCALE

MOUNTINGBRACKET | Fig. 27 |

| |

TO BEVEL CUT WITH YOUR MITER | |

SAW: |

|

Pull out the lock pin and lift saw arm to its full

height.

Loosen the miter lock handle. Rotate the miter lock handle approximately

Press the miter lock plate down with your thumb and hold.

Rotate the control arm until the pointer aligns with zero on the miter scale.

Release the miter lock plate.

Note: You can quickly locate zero by releasing the lock plate as you rotate the control arm. The lock plate will seat itself in one of the built4n positive stop notches, located in the miter table

frame.

•Tighten the miter lock handle securely.

,_ WARNING: To avoid serious personal injury, always tighten the miter lock handle securely

before making a cut. Failure to do so could result in movement of the control arm or miter table while making a cut.

20