REVERSIBLE

See Figure 5.

This tool has the feature of being reversible. The direction of rotation is controlled by a selector located above the switch trigger. With the drill held in normal operating position, the direction of rotation selector should be positioned to the left of the switch for drilling. The drilling direction is reversed when the selector is to the right of the switch. When the selector is in center position, the switch trigger is locked.

_i CAUTION: To prevent gear damage, always allow chuck to come to a complete stop before changing the direction of rotation or the two speed gear train

To stop, release switch trigger and allow the chuck to come to a complete stop.

_lb WARNING: Your drill should never be connected to power supply when you are assembling parts,

making adjustments, installing or removing drill bits, cleaning, or when not in use. Disconnecting your drill will prevent accidental starting that could cause serious personal injury.

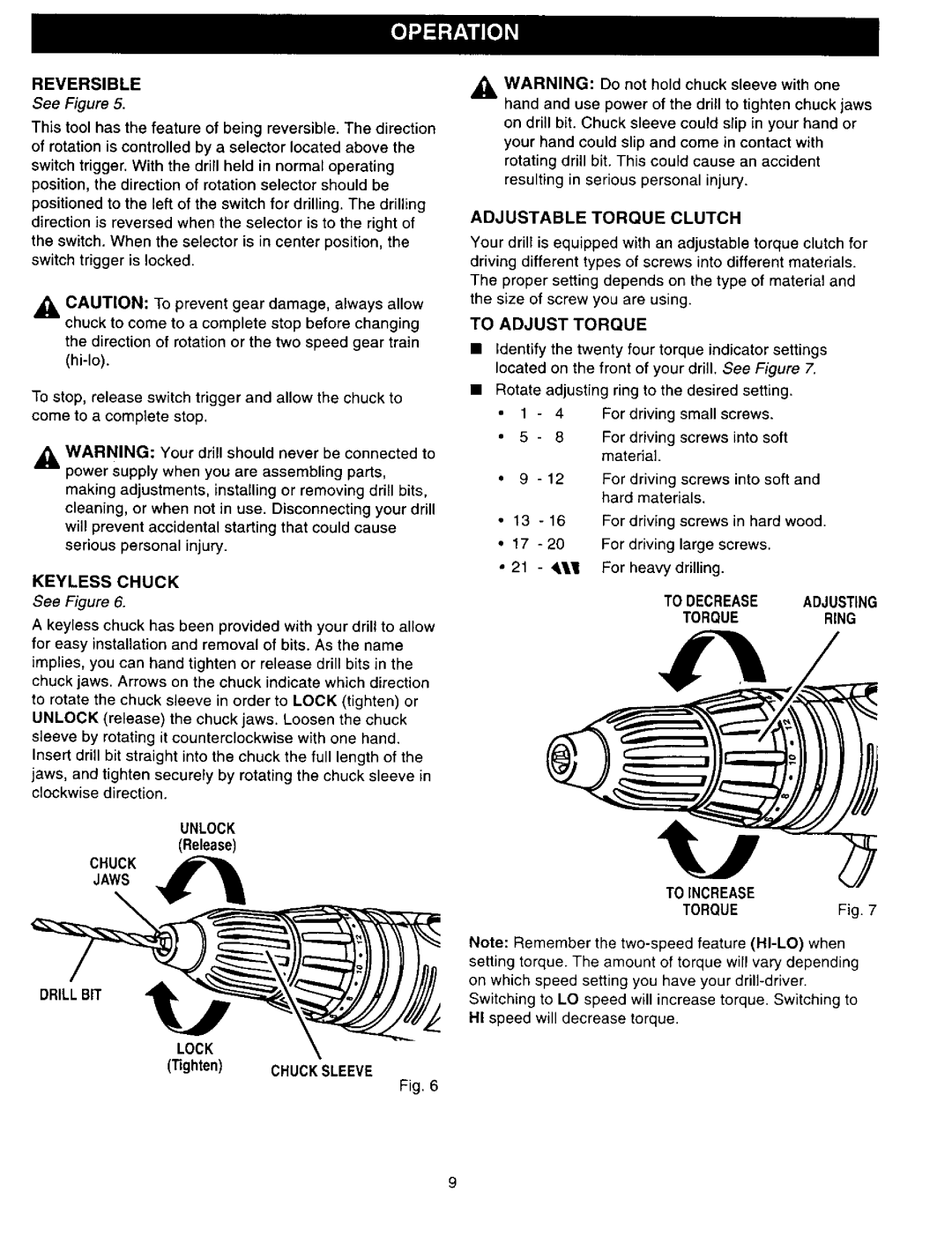

KEYLESS CHUCK

See Figure 6.

A keyless chuck has been provided with your drill to allow for easy installation and removal of bits. As the name implies, you can hand tighten or release drill bits in the chuck jaws. Arrows on the chuck indicate which direction to rotate the chuck sleeve in order to LOCK (tighten) or UNLOCK (release) the chuck jaws. Loosen the chuck sleeve by rotating it counterclockwise with one hand. Insert drill bit straight into the chuck the full length of the

jaws, and tighten securely by rotating the chuck sleeve in clockwise direction.

UNLOCK

(Release)

JAWS

CHUCK ,_

DRILLBIT

LOCK

(Tighten) CHUCKSLEEVE

Fig. 6

_IL WARNING: Do not hold chuck sleeve with one hand and use power of the drill to tighten chuck jaws on drill bit. Chuck sleeve could slip in your hand or your hand could slip and come in contact with rotating drill bit. This could cause an accident resulting in serious personal injury.

ADJUSTABLE TORQUE CLUTCH

Your drill is equipped with an adjustable torque clutch for driving different types of screws into different materials. The proper setting depends on the type of material and the size of screw you are using.

TO ADJUST TORQUE

•Identify the twenty four torque indicator settings located on the front of your drill. See Figure 7.

•Rotate adjusting ring to the desired setting.

1- 4 For driving small screws.

•5 - 8 For driving screws into soft material.

•9 - 12 For driving screws into soft and hard materials.

•13 - 16 For driving screws in hard wood.

•17 - 20 For driving large screws.

•21

TO DECREASE ADJUSTING

TORQUERING

T01NCREASE |

|

TORQUE | Fig. 7 |

Note: Remember the