Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR

ENGINE THROTTLE ADJUSTMENT TEST (continued)

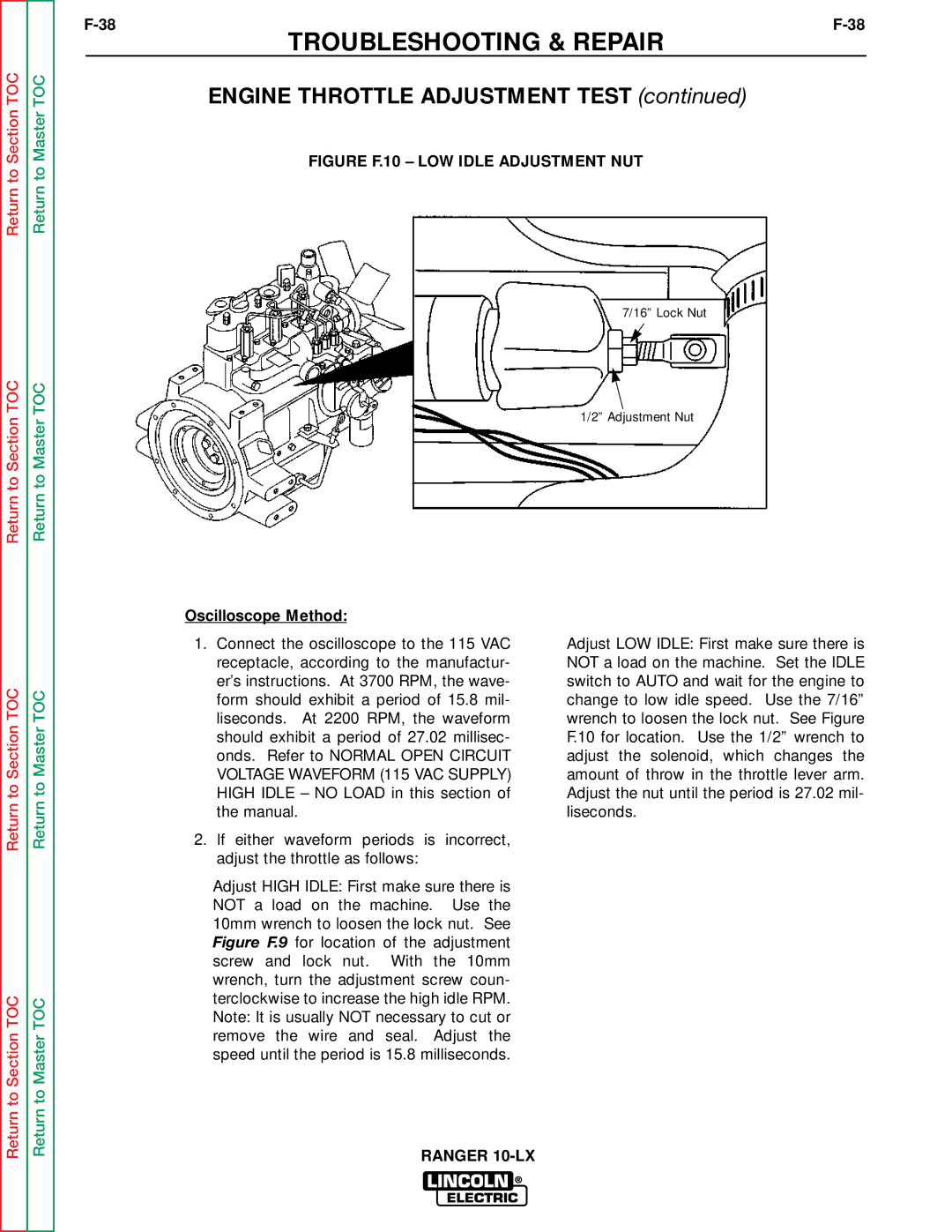

FIGURE F.10 – LOW IDLE ADJUSTMENT NUT

7/16” Lock Nut

1/2” Adjustment Nut

Oscilloscope Method:

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

1.Connect the oscilloscope to the 115 VAC receptacle, according to the manufactur- er’s instructions. At 3700 RPM, the wave- form should exhibit a period of 15.8 mil- liseconds. At 2200 RPM, the waveform should exhibit a period of 27.02 millisec- onds. Refer to NORMAL OPEN CIRCUIT VOLTAGE WAVEFORM (115 VAC SUPPLY) HIGH IDLE – NO LOAD in this section of the manual.

2.If either waveform periods is incorrect, adjust the throttle as follows:

Adjust HIGH IDLE: First make sure there is NOT a load on the machine. Use the 10mm wrench to loosen the lock nut. See Figure F.9 for location of the adjustment screw and lock nut. With the 10mm wrench, turn the adjustment screw coun- terclockwise to increase the high idle RPM. Note: It is usually NOT necessary to cut or remove the wire and seal. Adjust the speed until the period is 15.8 milliseconds.

Adjust LOW IDLE: First make sure there is NOT a load on the machine. Set the IDLE switch to AUTO and wait for the engine to change to low idle speed. Use the 7/16” wrench to loosen the lock nut. See Figure F.10 for location. Use the 1/2” wrench to adjust the solenoid, which changes the amount of throw in the throttle lever arm. Adjust the nut until the period is 27.02 mil- liseconds.

RANGER