Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR

AUXILIARY AND FIELD WINDING TEST (continued)

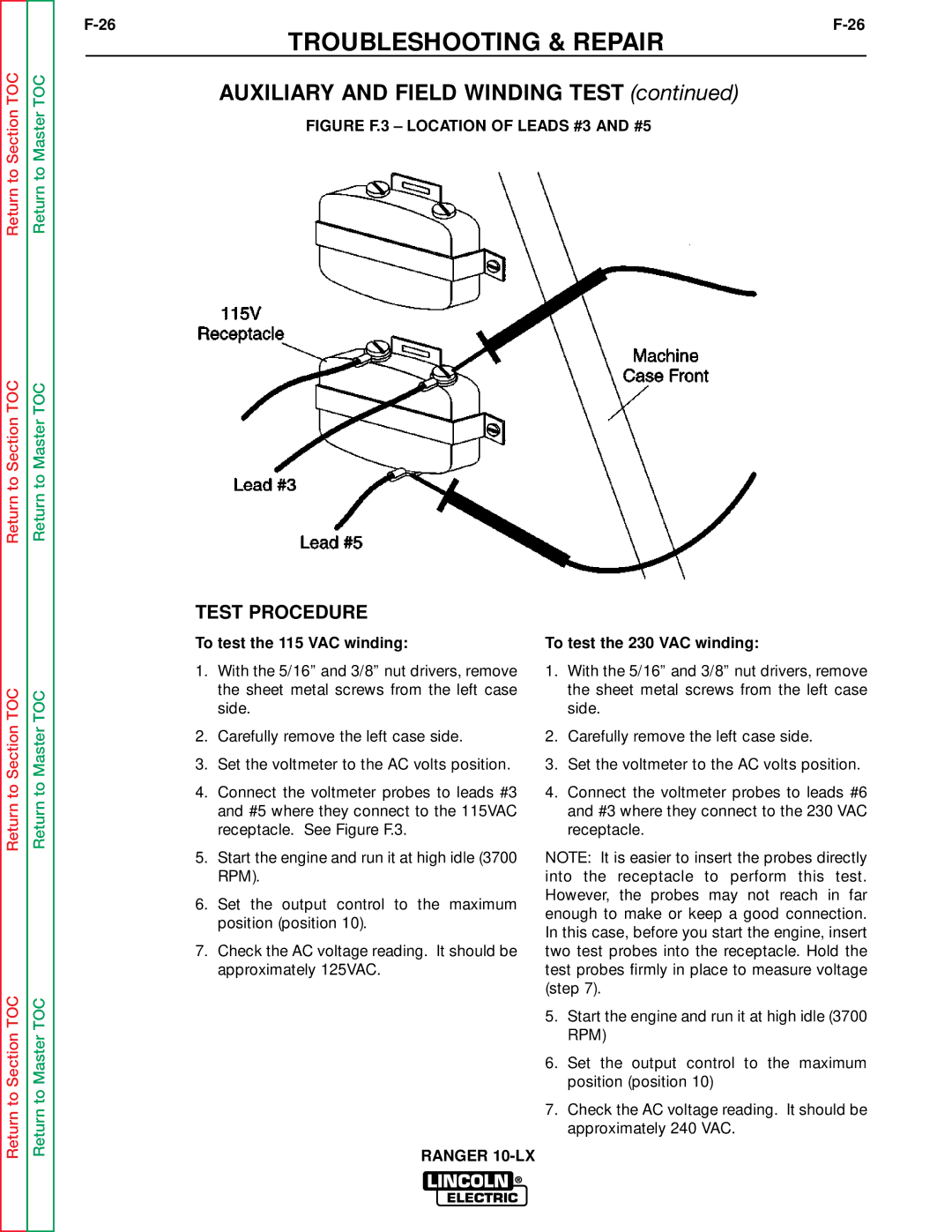

FIGURE F.3 – LOCATION OF LEADS #3 AND #5

TEST PROCEDURE

To test the 115 VAC winding: | To test the 230 VAC winding: |

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

1.With the 5/16” and 3/8” nut drivers, remove the sheet metal screws from the left case side.

2.Carefully remove the left case side.

3.Set the voltmeter to the AC volts position.

4.Connect the voltmeter probes to leads #3 and #5 where they connect to the 115VAC receptacle. See Figure F.3.

5.Start the engine and run it at high idle (3700 RPM).

6.Set the output control to the maximum position (position 10).

7.Check the AC voltage reading. It should be approximately 125VAC.

RANGER

1.With the 5/16” and 3/8” nut drivers, remove the sheet metal screws from the left case side.

2.Carefully remove the left case side.

3.Set the voltmeter to the AC volts position.

4.Connect the voltmeter probes to leads #6 and #3 where they connect to the 230 VAC receptacle.

NOTE: It is easier to insert the probes directly into the receptacle to perform this test. However, the probes may not reach in far enough to make or keep a good connection. In this case, before you start the engine, insert two test probes into the receptacle. Hold the test probes firmly in place to measure voltage (step 7).

5.Start the engine and run it at high idle (3700 RPM)

6.Set the output control to the maximum position (position 10)

7.Check the AC voltage reading. It should be approximately 240 VAC.