Return to Section TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR

STATOR AND/OR ROTOR REMOVAL

AND REPLACEMENT (continued)

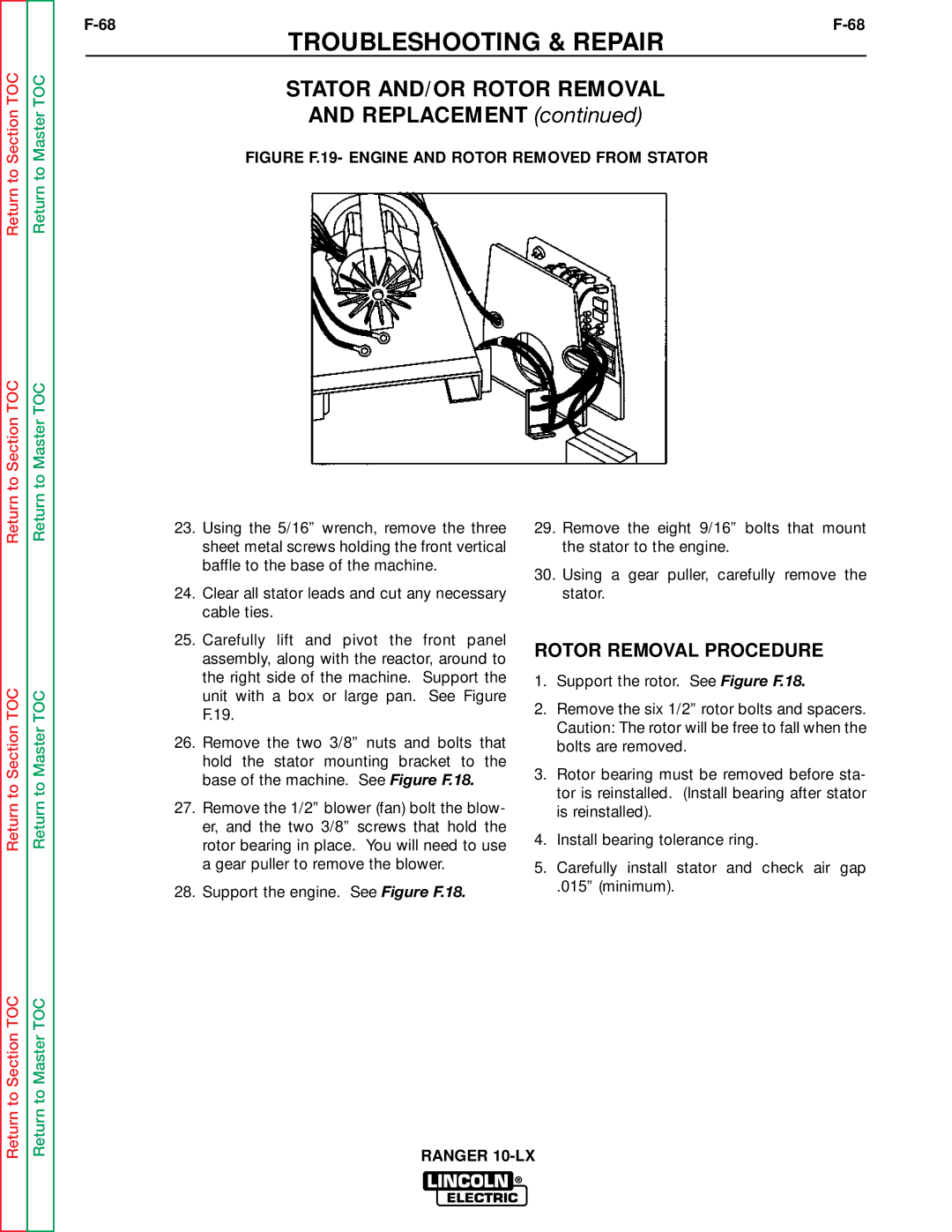

FIGURE F.19- ENGINE AND ROTOR REMOVED FROM STATOR

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

23.Using the 5/16” wrench, remove the three sheet metal screws holding the front vertical baffle to the base of the machine.

24.Clear all stator leads and cut any necessary cable ties.

25.Carefully lift and pivot the front panel assembly, along with the reactor, around to the right side of the machine. Support the unit with a box or large pan. See Figure F.19.

26.Remove the two 3/8” nuts and bolts that hold the stator mounting bracket to the base of the machine. See Figure F.18.

27.Remove the 1/2” blower (fan) bolt the blow- er, and the two 3/8” screws that hold the rotor bearing in place. You will need to use a gear puller to remove the blower.

28.Support the engine. See Figure F.18.

29.Remove the eight 9/16” bolts that mount the stator to the engine.

30.Using a gear puller, carefully remove the stator.

ROTOR REMOVAL PROCEDURE

1.Support the rotor. See Figure F.18.

2.Remove the six 1/2” rotor bolts and spacers. Caution: The rotor will be free to fall when the bolts are removed.

3.Rotor bearing must be removed before sta- tor is reinstalled. (Install bearing after stator is reinstalled).

4.Install bearing tolerance ring.

5.Carefully install stator and check air gap

.015” (minimum).

Return to Section TOC

Return to Master TOC

RANGER