Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

|

|

| |||||

|

|

|

| OPERATION | |||

| CONTROLS AND SETTINGS |

|

|

|

| ||

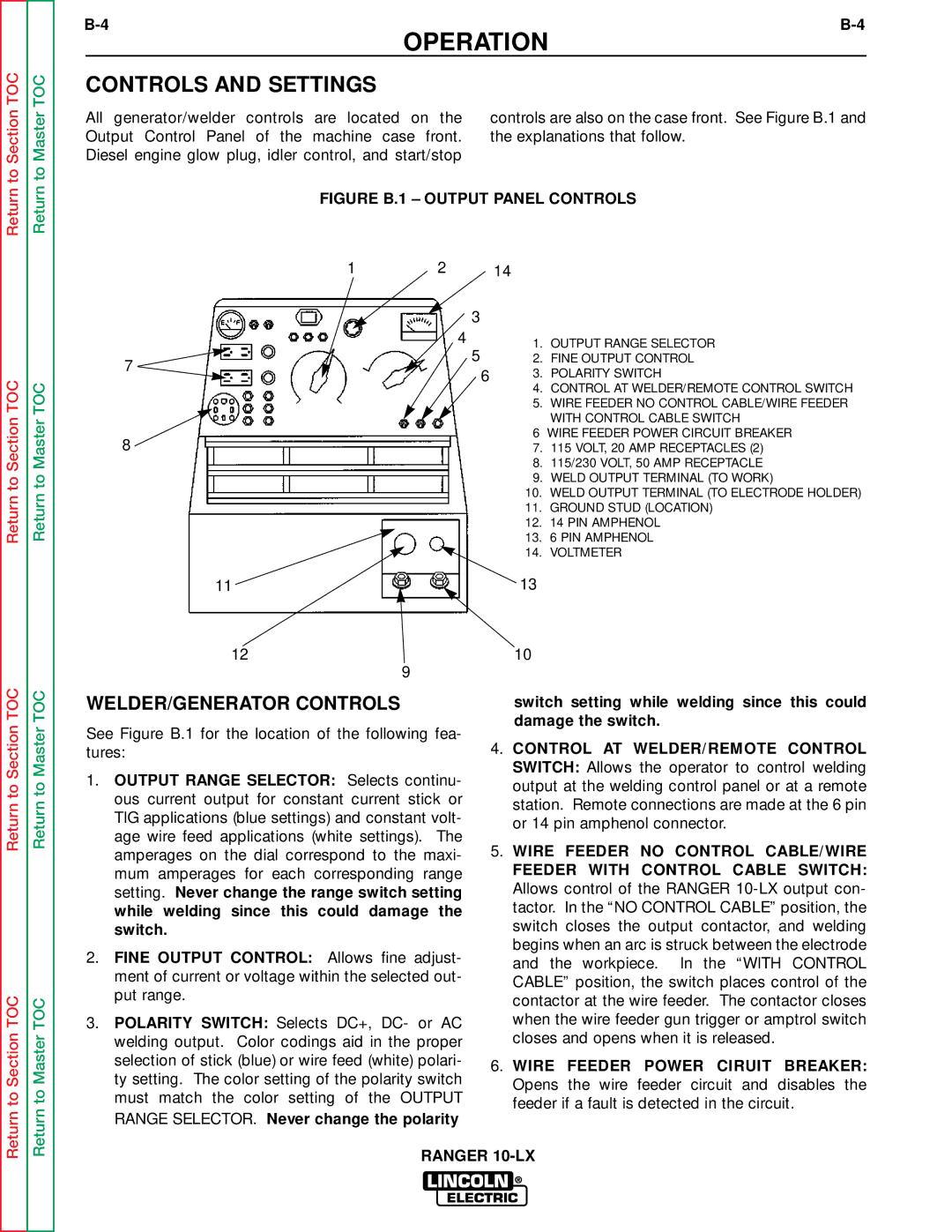

| All generator/welder controls are located on the | controls are also on the case front. See Figure B.1 and | |||||

| Output Control Panel of the machine case front. | the explanations that follow. | |||||

| Diesel engine glow plug, idler control, and start/stop |

| |||||

| FIGURE B.1 – OUTPUT PANEL CONTROLS | ||||||

|

|

|

|

|

|

| |

| 1 |

| 2 |

| 14 | ||

3

41. OUTPUT RANGE SELECTOR

7 |

|

| 5 |

| 2. FINE OUTPUT CONTROL | ||

6 | 3. POLARITY SWITCH | ||||||

| |||||||

|

|

|

|

| 4. CONTROL AT WELDER/REMOTE CONTROL SWITCH | ||

|

|

|

|

| 5. WIRE FEEDER NO CONTROL CABLE/WIRE FEEDER | ||

|

|

|

|

|

| WITH CONTROL CABLE SWITCH | |

8 |

|

|

|

| 6 WIRE FEEDER POWER CIRCUIT BREAKER | ||

|

|

|

| 7. 115 VOLT, 20 AMP RECEPTACLES (2) | |||

|

|

|

|

| 8. 115/230 VOLT, 50 AMP RECEPTACLE | ||

|

|

|

|

| 9. WELD OUTPUT TERMINAL (TO WORK) | ||

|

|

|

|

| 10. | WELD OUTPUT TERMINAL (TO ELECTRODE HOLDER) | |

|

|

|

|

| 11. | GROUND STUD (LOCATION) | |

|

|

|

|

| 12. | 14 PIN AMPHENOL | |

|

|

|

|

| 13. | 6 PIN AMPHENOL | |

|

|

|

|

| 14. | VOLTMETER | |

|

|

|

|

| 13 |

| |

| 11 |

|

|

|

| ||

| 12 |

|

| 10 |

| ||

9

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

WELDER/GENERATOR CONTROLS

See Figure B.1 for the location of the following fea- tures:

1.OUTPUT RANGE SELECTOR: Selects continu- ous current output for constant current stick or TIG applications (blue settings) and constant volt- age wire feed applications (white settings). The amperages on the dial correspond to the maxi- mum amperages for each corresponding range setting. Never change the range switch setting while welding since this could damage the switch.

2.FINE OUTPUT CONTROL: Allows fine adjust- ment of current or voltage within the selected out- put range.

3.POLARITY SWITCH: Selects DC+, DC- or AC welding output. Color codings aid in the proper selection of stick (blue) or wire feed (white) polari- ty setting. The color setting of the polarity switch must match the color setting of the OUTPUT RANGE SELECTOR. Never change the polarity

switch setting while welding since this could damage the switch.

4.CONTROL AT WELDER/REMOTE CONTROL SWITCH: Allows the operator to control welding output at the welding control panel or at a remote station. Remote connections are made at the 6 pin or 14 pin amphenol connector.

5.WIRE FEEDER NO CONTROL CABLE/WIRE FEEDER WITH CONTROL CABLE SWITCH: Allows control of the RANGER

6.WIRE FEEDER POWER CIRUIT BREAKER: Opens the wire feeder circuit and disables the feeder if a fault is detected in the circuit.

RANGER