Return to Section TOC

Return to Master TOC

OPERATION

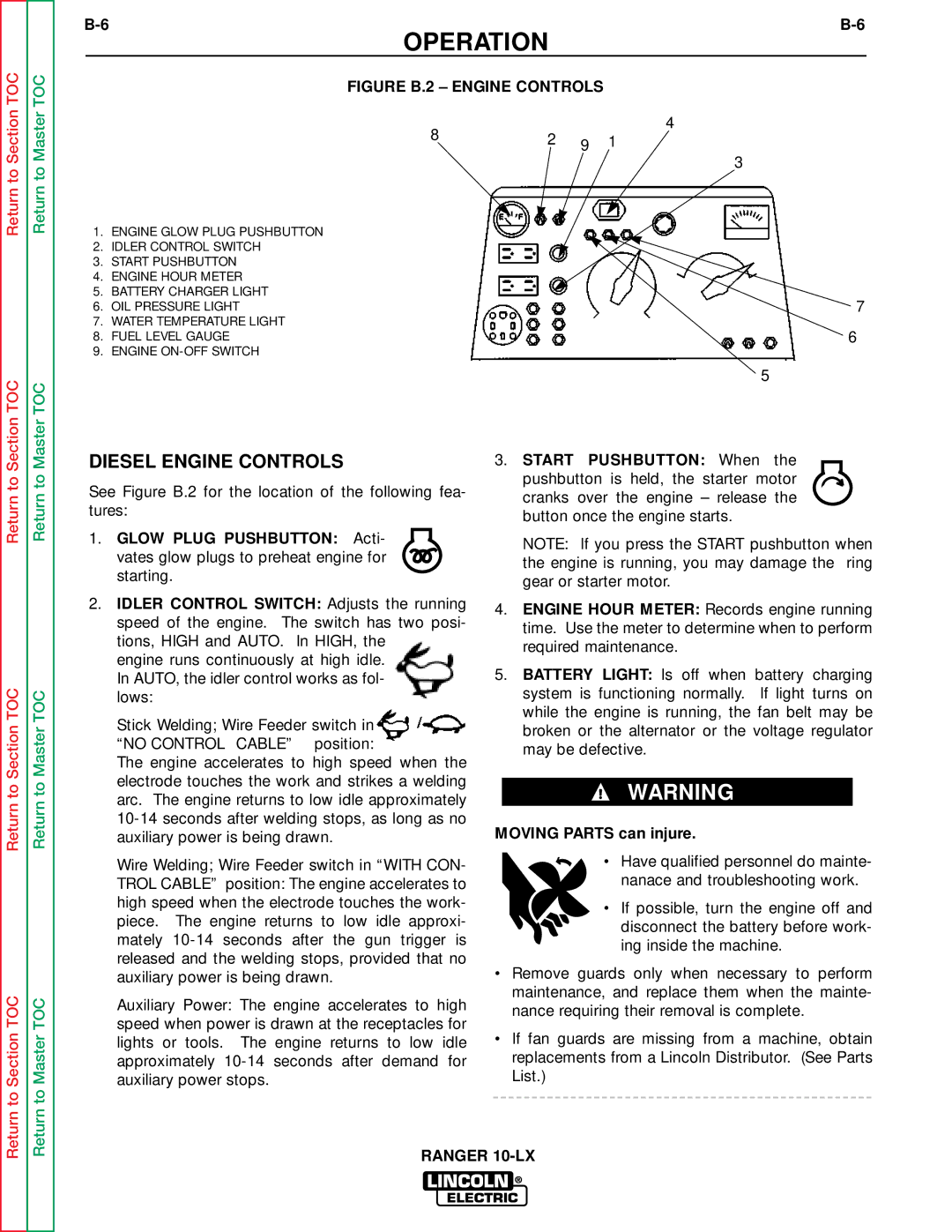

FIGURE B.2 – ENGINE CONTROLS

4

8 | 2 | 9 | 1 |

|

3

1.ENGINE GLOW PLUG PUSHBUTTON

2.IDLER CONTROL SWITCH

3.START PUSHBUTTON

4.ENGINE HOUR METER

5.BATTERY CHARGER LIGHT

6. | OIL PRESSURE LIGHT |

|

| 7 | |

7. | WATER TEMPERATURE LIGHT |

|

|

|

|

8. | FUEL LEVEL GAUGE |

| 6 |

| |

9. | ENGINE | 5 |

|

|

|

|

|

|

|

| |

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

DIESEL ENGINE CONTROLS

See Figure B.2 for the location of the following fea- tures:

1.GLOW PLUG PUSHBUTTON: Acti-

vates glow plugs to preheat engine for starting.

2.IDLER CONTROL SWITCH: Adjusts the running speed of the engine. The switch has two posi- tions, HIGH and AUTO. In HIGH, the

engine runs continuously at high idle. In AUTO, the idler control works as fol- lows:

Stick Welding; Wire Feeder switch in “NO CONTROL CABLE” position:

The engine accelerates to high speed when the electrode touches the work and strikes a welding arc. The engine returns to low idle approximately

Wire Welding; Wire Feeder switch in “WITH CON- TROL CABLE” position: The engine accelerates to high speed when the electrode touches the work- piece. The engine returns to low idle approxi- mately

Auxiliary Power: The engine accelerates to high speed when power is drawn at the receptacles for lights or tools. The engine returns to low idle approximately

3.START PUSHBUTTON: When the

pushbutton is held, the starter motor cranks over the engine – release the button once the engine starts.

NOTE: If you press the START pushbutton when the engine is running, you may damage the ring gear or starter motor.

4.ENGINE HOUR METER: Records engine running time. Use the meter to determine when to perform required maintenance.

5.BATTERY LIGHT: Is off when battery charging system is functioning normally. If light turns on while the engine is running, the fan belt may be broken or the alternator or the voltage regulator may be defective.

WARNING

MOVING PARTS can injure.

• Have qualified personnel do mainte- nanace and troubleshooting work.

• If possible, turn the engine off and disconnect the battery before work- ing inside the machine.

•Remove guards only when necessary to perform maintenance, and replace them when the mainte- nance requiring their removal is complete.

•If fan guards are missing from a machine, obtain replacements from a Lincoln Distributor. (See Parts List.)

RANGER