Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR

ENGINE THROTTLE ADJUSTMENT TEST (continued)

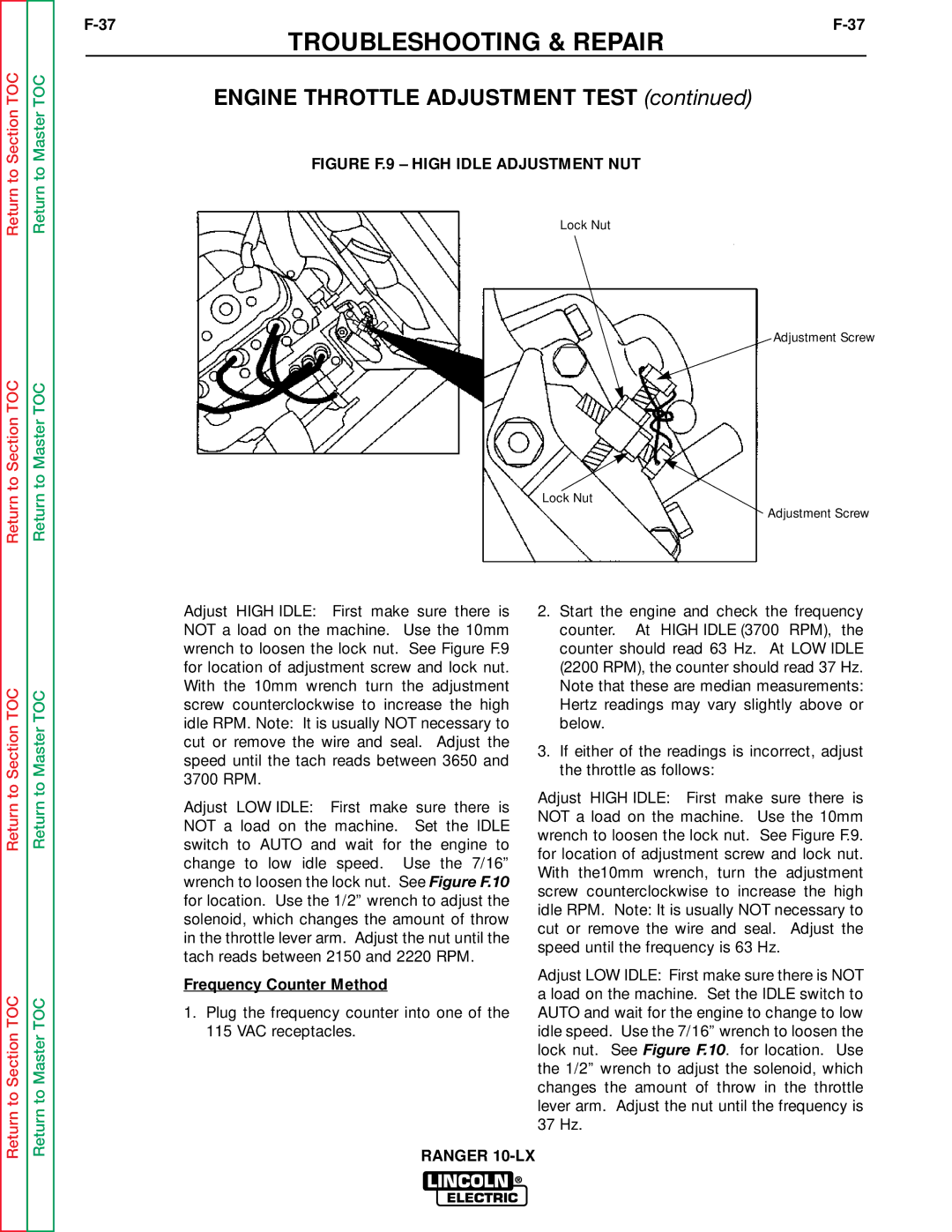

FIGURE F.9 – HIGH IDLE ADJUSTMENT NUT

Lock Nut

Adjustment Screw

Lock Nut

Adjustment Screw

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Adjust HIGH IDLE: First make sure there is NOT a load on the machine. Use the 10mm wrench to loosen the lock nut. See Figure F.9 for location of adjustment screw and lock nut. With the 10mm wrench turn the adjustment screw counterclockwise to increase the high idle RPM. Note: It is usually NOT necessary to cut or remove the wire and seal. Adjust the speed until the tach reads between 3650 and 3700 RPM.

Adjust LOW IDLE: First make sure there is NOT a load on the machine. Set the IDLE switch to AUTO and wait for the engine to change to low idle speed. Use the 7/16” wrench to loosen the lock nut. See Figure F.10 for location. Use the 1/2” wrench to adjust the solenoid, which changes the amount of throw in the throttle lever arm. Adjust the nut until the tach reads between 2150 and 2220 RPM.

Frequency Counter Method

1.Plug the frequency counter into one of the 115 VAC receptacles.

RANGER

2.Start the engine and check the frequency counter. At HIGH IDLE (3700 RPM), the counter should read 63 Hz. At LOW IDLE (2200 RPM), the counter should read 37 Hz. Note that these are median measurements: Hertz readings may vary slightly above or below.

3.If either of the readings is incorrect, adjust the throttle as follows:

Adjust HIGH IDLE: First make sure there is NOT a load on the machine. Use the 10mm wrench to loosen the lock nut. See Figure F.9. for location of adjustment screw and lock nut. With the10mm wrench, turn the adjustment screw counterclockwise to increase the high idle RPM. Note: It is usually NOT necessary to cut or remove the wire and seal. Adjust the speed until the frequency is 63 Hz.

Adjust LOW IDLE: First make sure there is NOT a load on the machine. Set the IDLE switch to AUTO and wait for the engine to change to low idle speed. Use the 7/16” wrench to loosen the lock nut. See Figure F.10. for location. Use the 1/2” wrench to adjust the solenoid, which changes the amount of throw in the throttle lever arm. Adjust the nut until the frequency is 37 Hz.