Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

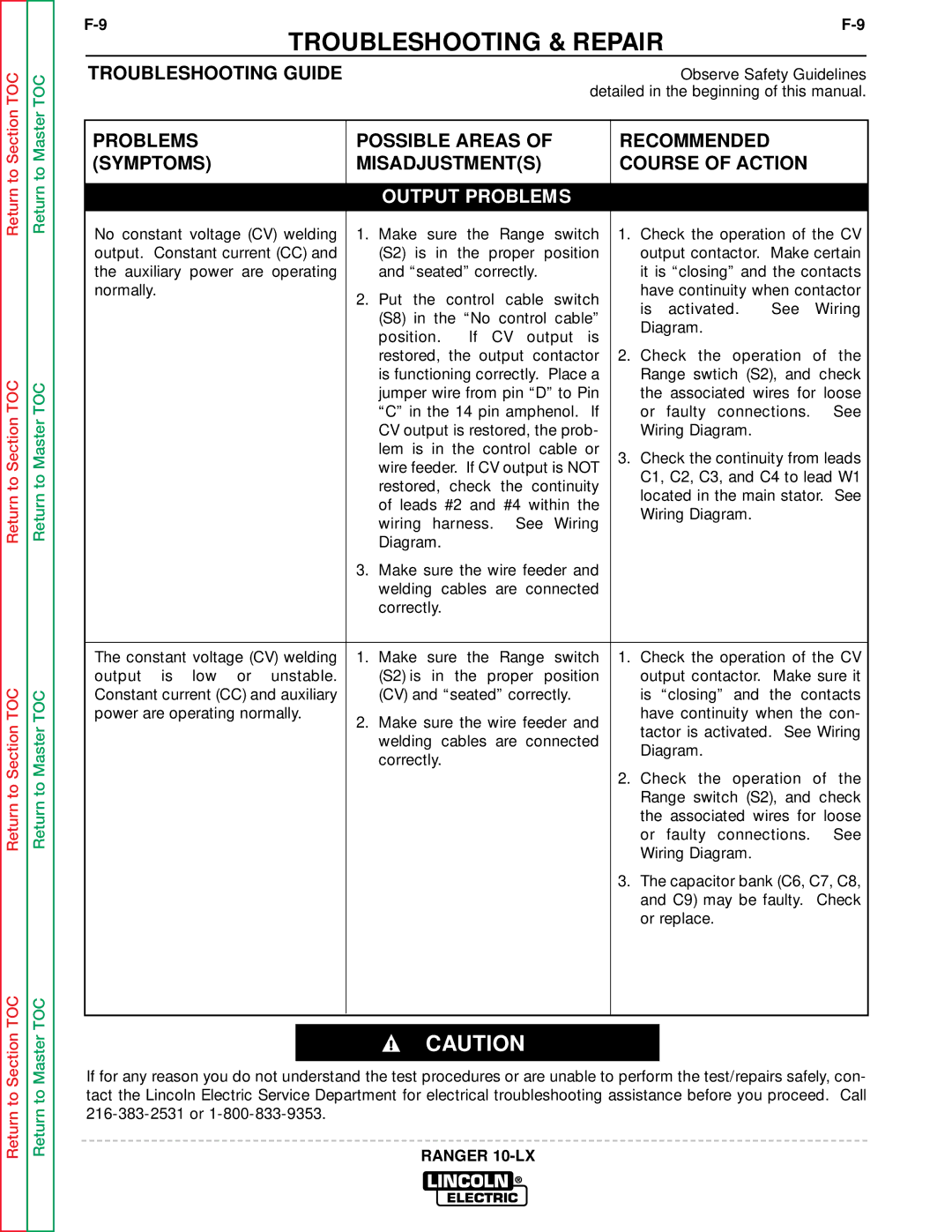

| TROUBLESHOOTING & REPAIR | |

| TROUBLESHOOTING GUIDE | Observe Safety Guidelines |

|

| detailed in the beginning of this manual. |

PROBLEMS | POSSIBLE AREAS OF |

| RECOMMENDED |

|

| |||||

(SYMPTOMS) | MISADJUSTMENT(S) |

| COURSE OF ACTION |

| ||||||

|

|

|

|

|

|

| ||||

| OUTPUT PROBLEMS |

|

|

|

|

| ||||

No constant voltage (CV) welding | 1. Make sure the Range switch | 1. | Check the operation of the CV | |||||||

output. Constant current (CC) and | (S2) is in the proper position |

| output contactor. Make certain | |||||||

the auxiliary power are operating | and “seated” correctly. |

|

| it is “closing” and the contacts | ||||||

normally. | 2. Put | the | control | cable | switch |

| have continuity when contactor | |||

|

| is | activated. | See | Wiring | |||||

| (S8) | in the “No | control | cable” |

| |||||

|

| Diagram. |

|

| ||||||

| position. | If CV output is |

|

|

| |||||

|

|

|

|

|

| |||||

| restored, | the output contactor | 2. Check the operation of the | |||||||

| is functioning correctly. Place a |

| Range swtich (S2), and check | |||||||

| jumper wire from pin “D” to Pin |

| the associated wires for loose | |||||||

| “C” in the 14 pin amphenol. If |

| or | faulty connections. | See | |||||

| CV output is restored, the prob- |

| Wiring Diagram. |

|

| |||||

| lem | is in | the control cable or | 3. Check the continuity from leads | ||||||

| wire feeder. If CV output is NOT | |||||||||

|

| C1, C2, C3, and C4 to lead W1 | ||||||||

| restored, | check | the continuity |

| ||||||

|

| located in the main stator. See | ||||||||

| of leads #2 and #4 within the |

| ||||||||

|

| Wiring Diagram. |

|

| ||||||

| wiring harness. | See | Wiring |

|

|

| ||||

|

|

|

|

|

| |||||

| Diagram. |

|

|

|

|

|

|

|

| |

| 3. Make sure the wire feeder and |

|

|

|

|

| ||||

| welding cables | are connected |

|

|

|

|

| |||

| correctly. |

|

|

|

|

|

|

|

| |

|

|

|

| |||||||

The constant voltage (CV) welding | 1. Make sure the Range switch | 1. | Check the operation of the CV | |||||||

output is low or unstable. | (S2) is in | the proper position |

| output contactor. | Make sure it | |||||

Constant current (CC) and auxiliary | (CV) and “seated” correctly. |

| is “closing” and the contacts | |||||||

power are operating normally. | 2. Make sure the wire feeder and |

| have continuity when the con- | |||||||

|

| tactor is activated. See Wiring | ||||||||

| welding cables | are connected |

| |||||||

|

| Diagram. |

|

| ||||||

| correctly. |

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

| 2. Check the operation of the | ||||

|

|

|

|

|

|

| Range switch (S2), and check | |||

|

|

|

|

|

|

| the associated wires for loose | |||

|

|

|

|

|

|

| or | faulty connections. | See | |

|

|

|

|

|

|

| Wiring Diagram. |

|

| |

|

|

|

|

|

| 3. The capacitor bank (C6, C7, C8, | ||||

|

|

|

|

|

|

| and C9) may be faulty. Check | |||

|

|

|

|

|

|

| or replace. |

|

| |

|

|

|

|

|

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

RANGER