TOC

TOC

THEORY OF OPERATION

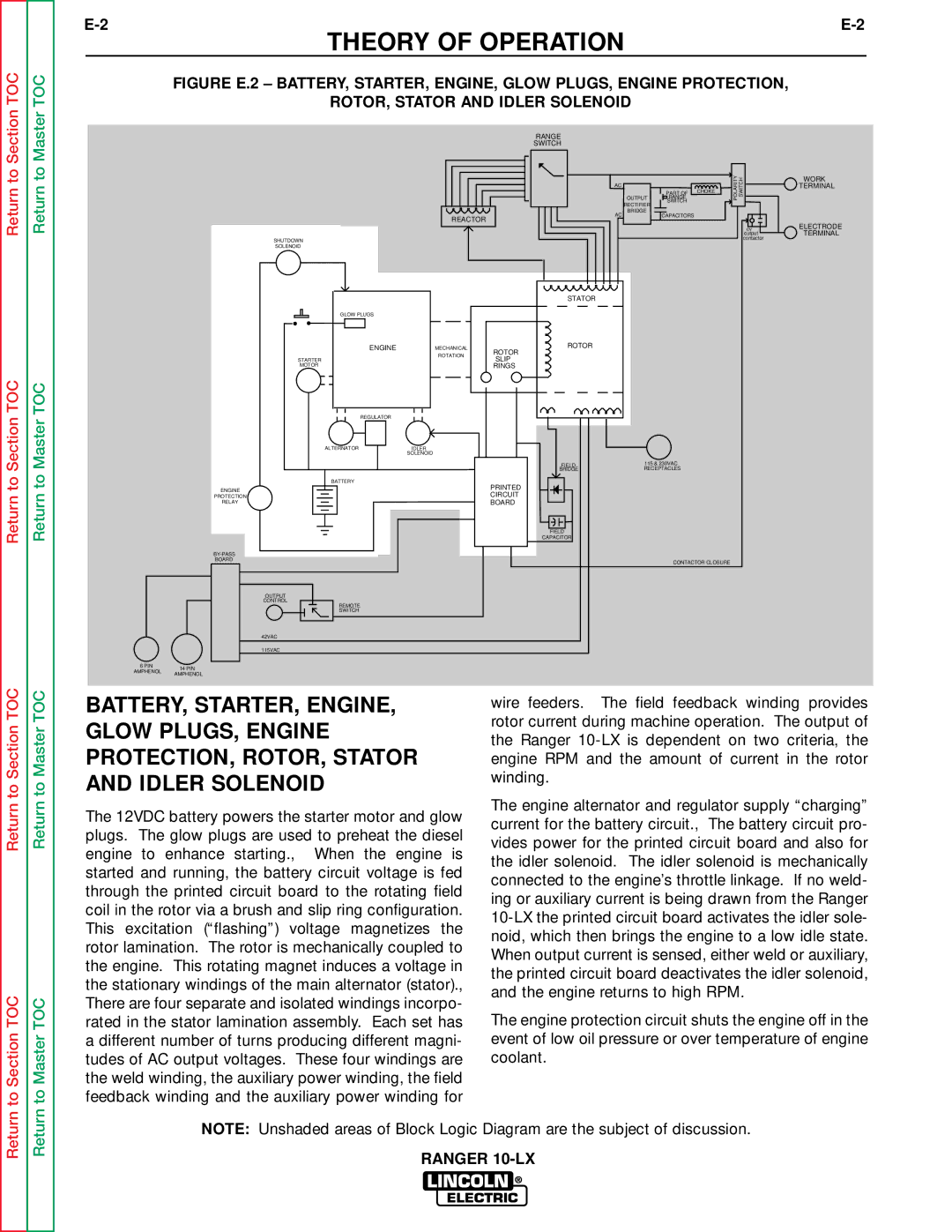

FIGURE E.2 – BATTERY, STARTER, ENGINE, GLOW PLUGS, ENGINE PROTECTION,

ROTOR, STATOR AND IDLER SOLENOID

Return to Section

Return to Section TOC

Return to Master

Return to Master TOC

|

| RANGE |

|

|

|

|

|

| SWITCH |

|

|

|

|

|

| AC | OUTPUT | RANGE |

| POLARITY SWITCH |

|

|

|

| PART OF | CHOKE |

|

|

|

| RECTIFIER | SWITCH |

|

|

|

|

|

|

|

| |

|

| AC | BRIDGE | CAPACITORS |

|

|

| REACTOR |

|

|

| ||

|

|

|

|

|

| |

|

|

|

|

|

| cv |

|

|

|

|

|

| output |

SHUTDOWN |

|

|

|

|

| contactor |

|

|

|

|

|

| |

SOLENOID |

|

|

|

|

|

|

|

| STATOR |

|

|

|

|

GLOW PLUGS |

|

|

|

|

|

|

ENGINE | MECHANICAL | ROTOR |

|

|

|

|

ROTOR |

|

|

|

| ||

| ROTATION |

|

|

|

| |

STARTER | SLIP |

|

|

|

| |

|

|

|

|

| ||

MOTOR |

| RINGS |

|

|

|

|

REGULATOR |

|

|

|

|

|

|

ALTERNATOR | IDLER |

|

|

|

|

|

| SOLENOID |

|

|

|

|

|

|

| FIELD | 115 & 230VAC |

|

| |

|

| BRIDGE | RECEPTACLES |

|

| |

BATTERY |

| PRINTED |

|

|

|

|

ENGINE |

|

|

|

|

| |

| CIRCUIT |

|

|

|

| |

PROTECTION |

|

|

|

|

| |

RELAY |

| BOARD |

|

|

|

|

|

| FIELD |

|

|

|

|

|

| CAPACITOR |

|

|

|

|

|

|

|

|

|

| |

BOARD |

|

|

| CONTACTOR CLOSURE |

| |

|

|

|

|

| ||

OUTPUT |

|

|

|

|

|

|

CONTROL |

|

|

|

|

|

|

REMOTE |

|

|

|

|

|

|

SWITCH |

|

|

|

|

|

|

42VAC |

|

|

|

|

|

|

115VAC |

|

|

|

|

|

|

6 PIN | 14 PIN | |

AMPHENOL | ||

AMPHENOL | ||

|

WORK

TERMINAL

ELECTRODE TERMINAL

Return to Section TOC

to Section TOC

Return to Master TOC

to Master TOC

BATTERY, STARTER, ENGINE, GLOW PLUGS, ENGINE PROTECTION, ROTOR, STATOR AND IDLER SOLENOID

The 12VDC battery powers the starter motor and glow plugs. The glow plugs are used to preheat the diesel engine to enhance starting., When the engine is started and running, the battery circuit voltage is fed through the printed circuit board to the rotating field coil in the rotor via a brush and slip ring configuration. This excitation (“flashing”) voltage magnetizes the rotor lamination. The rotor is mechanically coupled to the engine. This rotating magnet induces a voltage in the stationary windings of the main alternator (stator)., There are four separate and isolated windings incorpo- rated in the stator lamination assembly. Each set has a different number of turns producing different magni- tudes of AC output voltages. These four windings are the weld winding, the auxiliary power winding, the field feedback winding and the auxiliary power winding for

wire feeders. The field feedback winding provides rotor current during machine operation. The output of the Ranger

The engine alternator and regulator supply “charging” current for the battery circuit., The battery circuit pro- vides power for the printed circuit board and also for the idler solenoid. The idler solenoid is mechanically connected to the engine’s throttle linkage. If no weld- ing or auxiliary current is being drawn from the Ranger

The engine protection circuit shuts the engine off in the event of low oil pressure or over temperature of engine coolant.

Return

Return

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.

RANGER