CUSTOMER RESPONSIBtLmTIE$

,Read and follow the maintenance schedule and the maintenance procedures listed in this section,

MAINTENANCE SCHEDULE |

| //__/',,_//_ |

|

Fill in dates as you | __/_ | _x_" | Service Dates |

complete regular service. |

|

| |

Check for loose fasteners | X |

|

|

Check scraper and shoes for wear | _ X |

| |

Clean Blade | X | X |

|

Lubricate Blade |

| X |

|

CHECK FOR LOOSE FASTENERS

,During the operating season, check al! bolts, nuts and hairpin cotters to be sure they are secure.

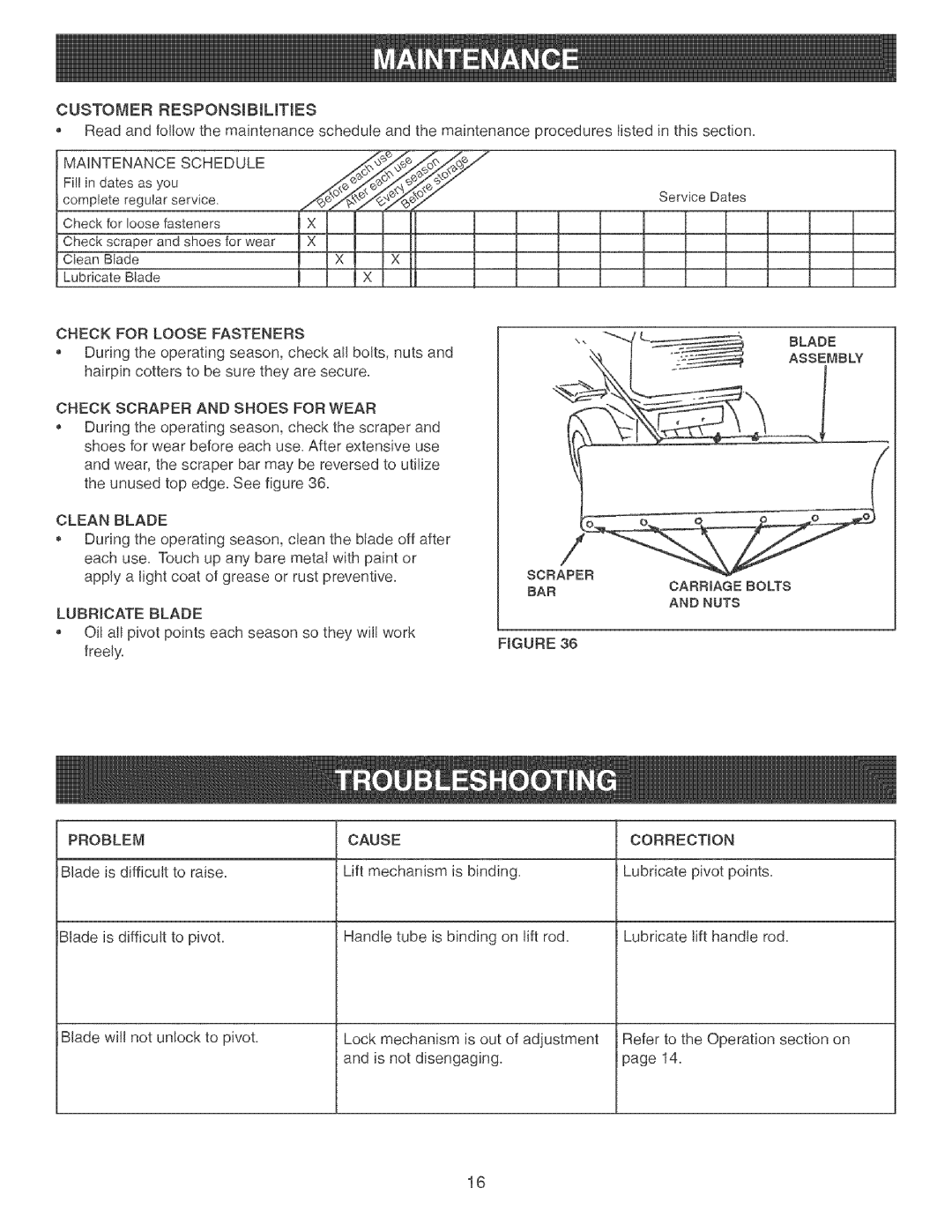

CHECK SCRAPER AND SHOES FOR WEAR

,During the operating season, check the scraper and shoes for wear before each use. After extensive use and wear, the scraper bar may be reversed to utilize the unused top edge. See figure 36.

CLEAN BLADE

•During the operating season, clean the blade off after each use. Touch up any bare metal with paint or apply a light coat of grease or rust preventive.

LUBRICATE BLADE

Oil al! pivot points each season so they will work freely.

BLADE

ASSEMBLY

SCRAPER

BARCABRtAGEBO_S

AND NUTS

FIGURE 36

PROBLEM |

| CAUSE | CORRECTION | |

Blade is difficult | to raise. | Lift mechanism is binding. | Lubricate | pivot points. |

Blade is difficult | to pivot. | Handle tube is binding on lift rod. | Lubricate | lift handle rod. |

Blade will not unlock to pivot.

Lock mechanism is out of adjustment | Refer | to the Operation section on |

and is not disengaging. | page | 14. |

16