917.272057 specifications

The Craftsman 917.272057 is a riding lawn mower designed for homeowners who seek an efficient and reliable solution for maintaining their lawns. With its powerful engine and advanced features, it stands out as a versatile tool for lawn care.One of the main highlights of the Craftsman 917.272057 is its robust 19.5 HP Briggs & Stratton engine. This powerful engine not only provides ample power for cutting grass efficiently but also ensures smooth operation across various terrains. The automatic transmission further enhances the user experience by allowing for seamless speed adjustments without the need for manual shifting.

The mower showcases a cutting deck width of 42 inches, making it suitable for medium to large yards. This size strikes a balance between maneuverability and efficiency, enabling users to cover larger areas while navigating around obstacles such as trees and flower beds. The cutting height can be easily adjusted with a simple lever, allowing users to customize grass length according to their preferences and seasonal needs.

One of the standout features of the Craftsman 917.272057 is its mulching capability. The mower comes equipped with a mulching kit, which allows users to finely chop grass clippings, returning nutrients to the soil. This not only promotes a healthier lawn but also reduces the need for bagging or disposal of clippings.

The construction of the 917.272057 is designed with durability in mind. Its heavy-duty frame and reinforced cutting deck ensure longevity, even when used on varied landscapes. Furthermore, the comfortable high-back seat and easy-to-reach controls enhance operator comfort during longer mowing sessions.

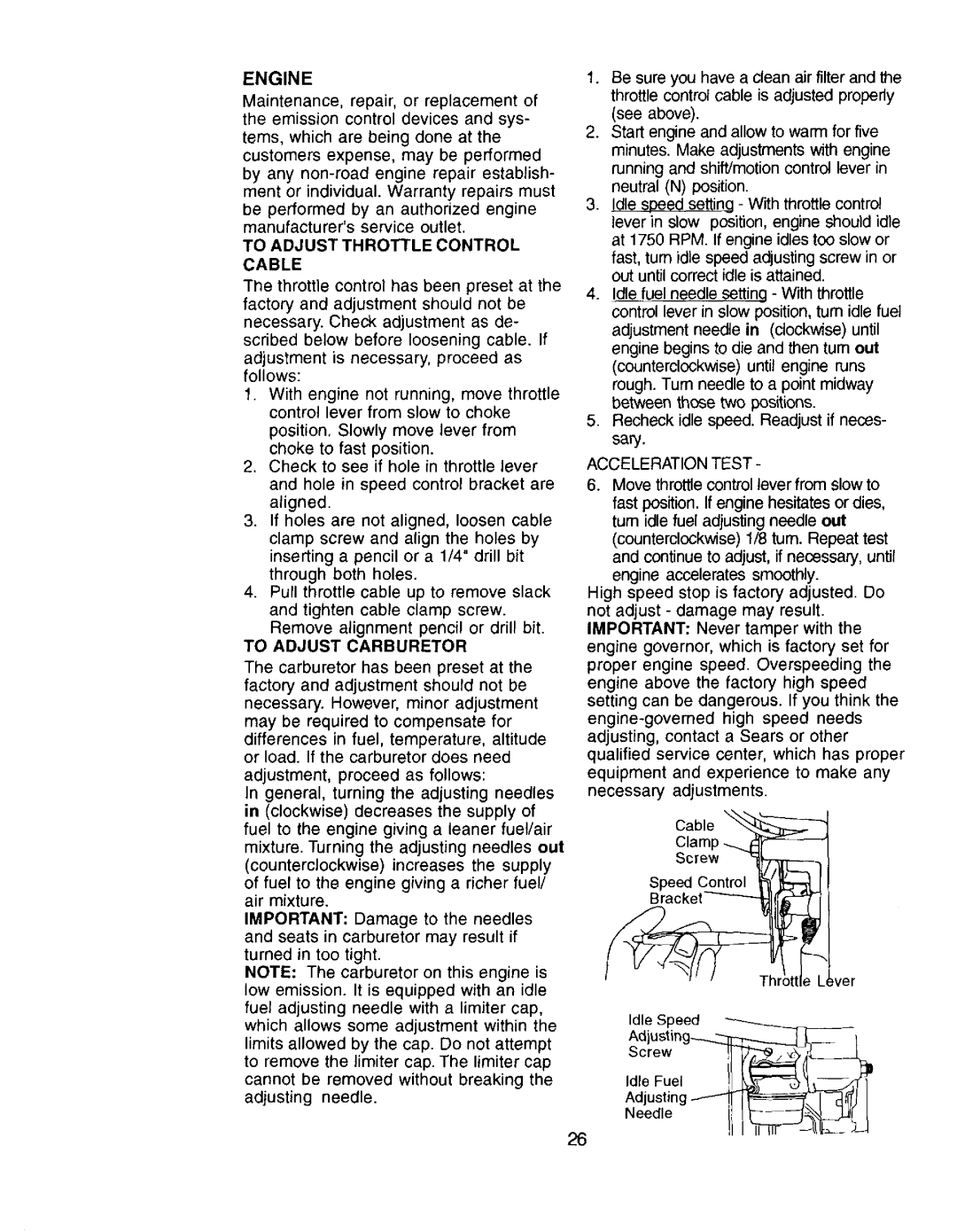

In terms of maintenance, the Craftsman 917.272057 is user-friendly. Accessing the engine and other vital components for routine checks and servicing is straightforward, making it easier for owners to ensure optimal performance throughout the mowing season.

In summary, the Craftsman 917.272057 is a powerful and efficient riding lawn mower equipped with essential features that cater to the diverse needs of lawn care. With a robust engine, adjustable cutting deck, mulching capabilities, and user-friendly design, it offers a comprehensive solution for homeowners seeking an effective way to keep their lawns looking pristine. Whether tackling a small yard or a larger property, this mower combines performance, comfort, and durability, making it a valuable addition to any homeowner's gardening arsenal.