Beer Keg Installation Instructions

Beer Keg Installation Instructions

INSTALLATION OF THE CO2 AIR LINE HOSE

CONNECTING THE BEER TOWER TO COUPLER

•Attach the end of the air line (red) hose provided to the hose connection on the keg coupler.

•Make sure the washer is properly inserted into the wing nut.

•Make sure the small round bead is in place (dropped down into the top of the coupler).

•Make sure the ball retainer is in place on the coupler, with the ‘arms’ down into the coupler.

•Place wing nut into the top of the coupler turning until tight.

HOW TO TAP A KEG OF BEER

•Make sure that the CO2 is turned off, and the Secondary valve on the regulator is in the ‘Closed’ position.

•Pull out and release the pressure release valve on the Coupler to purge any air pressure.

•Make sure the beer tower faucet is in the closed position.

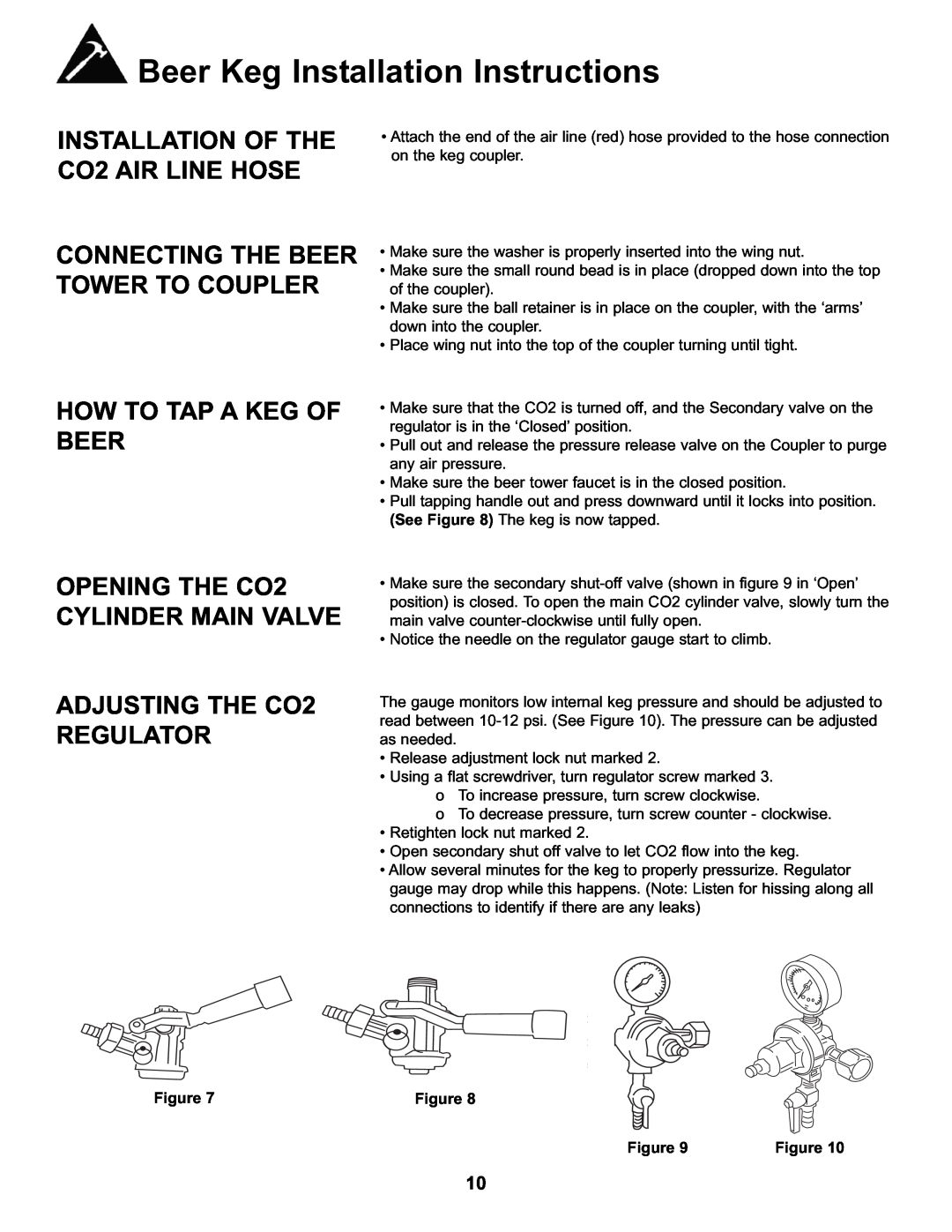

•Pull tapping handle out and press downward until it locks into position. (See Figure 8) The keg is now tapped.

OPENING THE CO2 CYLINDER MAIN VALVE

ADJUSTING THE CO2 REGULATOR

•Make sure the secondary

•Notice the needle on the regulator gauge start to climb.

The gauge monitors low internal keg pressure and should be adjusted to read between

•Release adjustment lock nut marked 2.

•Using a flat screwdriver, turn regulator screw marked 3. o To increase pressure, turn screw clockwise.

o To decrease pressure, turn screw counter - clockwise.

•Retighten lock nut marked 2.

•Open secondary shut off valve to let CO2 flow into the keg.

•Allow several minutes for the keg to properly pressurize. Regulator gauge may drop while this happens. (Note: Listen for hissing along all connections to identify if there are any leaks)

Figure 7 | Figure 8 |

Figure 9 | Figure 10 |

10