www.bradyeurope.com

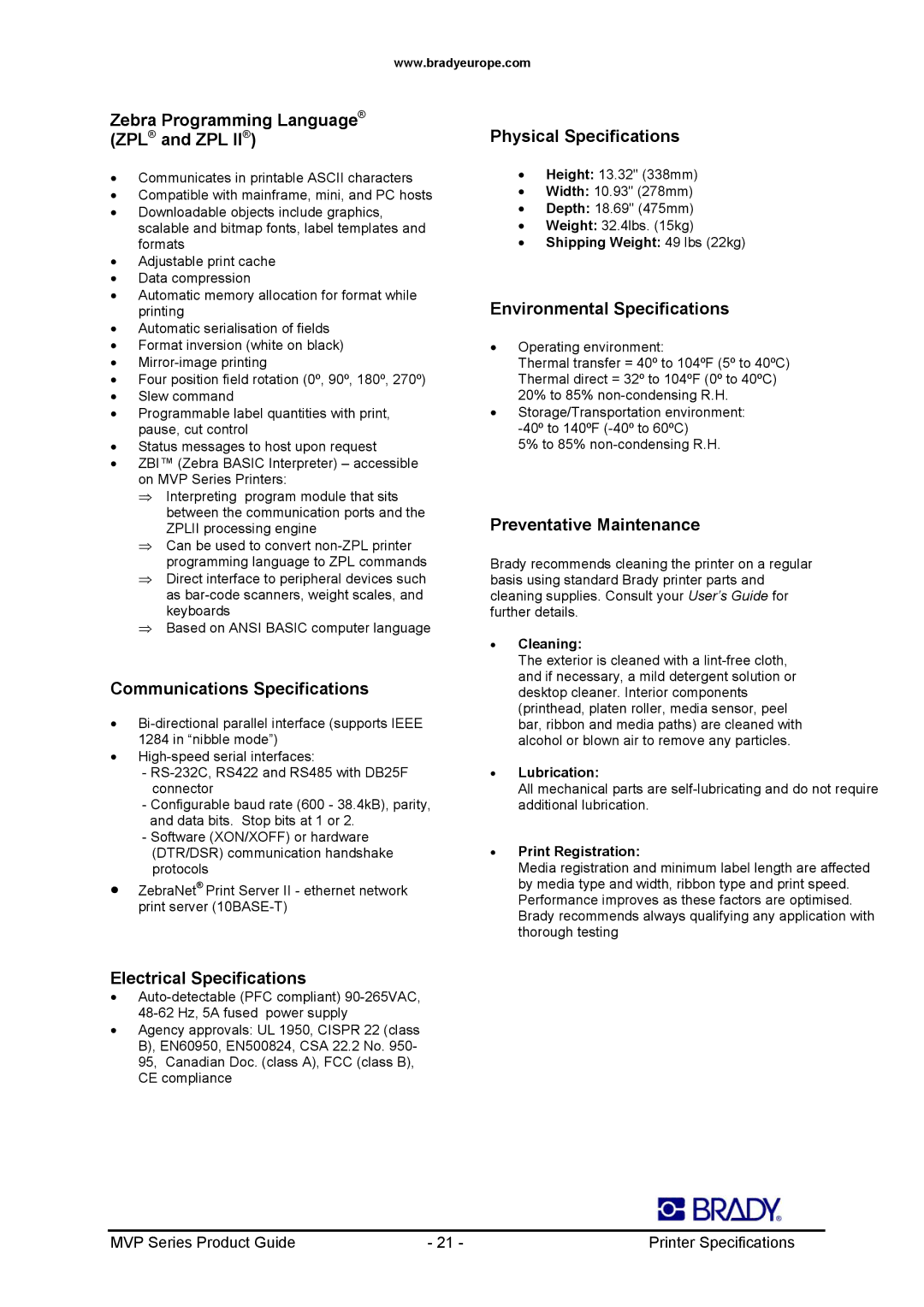

Zebra Programming Language® (ZPL® and ZPL II®)

•Communicates in printable ASCII characters

•Compatible with mainframe, mini, and PC hosts

•Downloadable objects include graphics, scalable and bitmap fonts, label templates and formats

•Adjustable print cache

•Data compression

•Automatic memory allocation for format while printing

•Automatic serialisation of fields

•Format inversion (white on black)

•

•Four position field rotation (0º, 90º, 180º, 270º)

•Slew command

•Programmable label quantities with print, pause, cut control

•Status messages to host upon request

•ZBI™ (Zebra BASIC Interpreter) – accessible on MVP Series Printers:

⇒Interpreting program module that sits between the communication ports and the ZPLII processing engine

⇒Can be used to convert

⇒Direct interface to peripheral devices such as

⇒Based on ANSI BASIC computer language

Communications Specifications

•

•

-

-Configurable baud rate (600 - 38.4kB), parity, and data bits. Stop bits at 1 or 2.

-Software (XON/XOFF) or hardware (DTR/DSR) communication handshake protocols

•ZebraNet® Print Server II - ethernet network print server

Physical Specifications

•Height: 13.32" (338mm)

•Width: 10.93" (278mm)

•Depth: 18.69" (475mm)

•Weight: 32.4lbs. (15kg)

•Shipping Weight: 49 lbs (22kg)

Environmental Specifications

•Operating environment:

Thermal transfer = 40º to 104ºF (5º to 40ºC) Thermal direct = 32º to 104ºF (0º to 40ºC) 20% to 85%

•Storage/Transportation environment:

5% to 85%

Preventative Maintenance

Brady recommends cleaning the printer on a regular basis using standard Brady printer parts and cleaning supplies. Consult your User’s Guide for further details.

•Cleaning:

The exterior is cleaned with a

•Lubrication:

All mechanical parts are

•Print Registration:

Media registration and minimum label length are affected by media type and width, ribbon type and print speed. Performance improves as these factors are optimised. Brady recommends always qualifying any application with thorough testing

Electrical Specifications

•

•Agency approvals: UL 1950, CISPR 22 (class B), EN60950, EN500824, CSA 22.2 No. 950- 95, Canadian Doc. (class A), FCC (class B), CE compliance

MVP Series Product Guide | - 21 - | Printer Specifications |