Selecting Media and Ribbon

Because the media and ribbon used will determine the printer’s heat and speed settings, consider these factors when selecting your thermal transfer stock and ribbon combination:

The combination of label facestocks / topcoatings and ribbon formulation may affect image quality.

The ribbon backcoating can provide printhead protection and, depending upon the formulation, help reduce static

The use of a ribbon that is slightly wider than the media backing material (if any) can protect the printhead against wear.

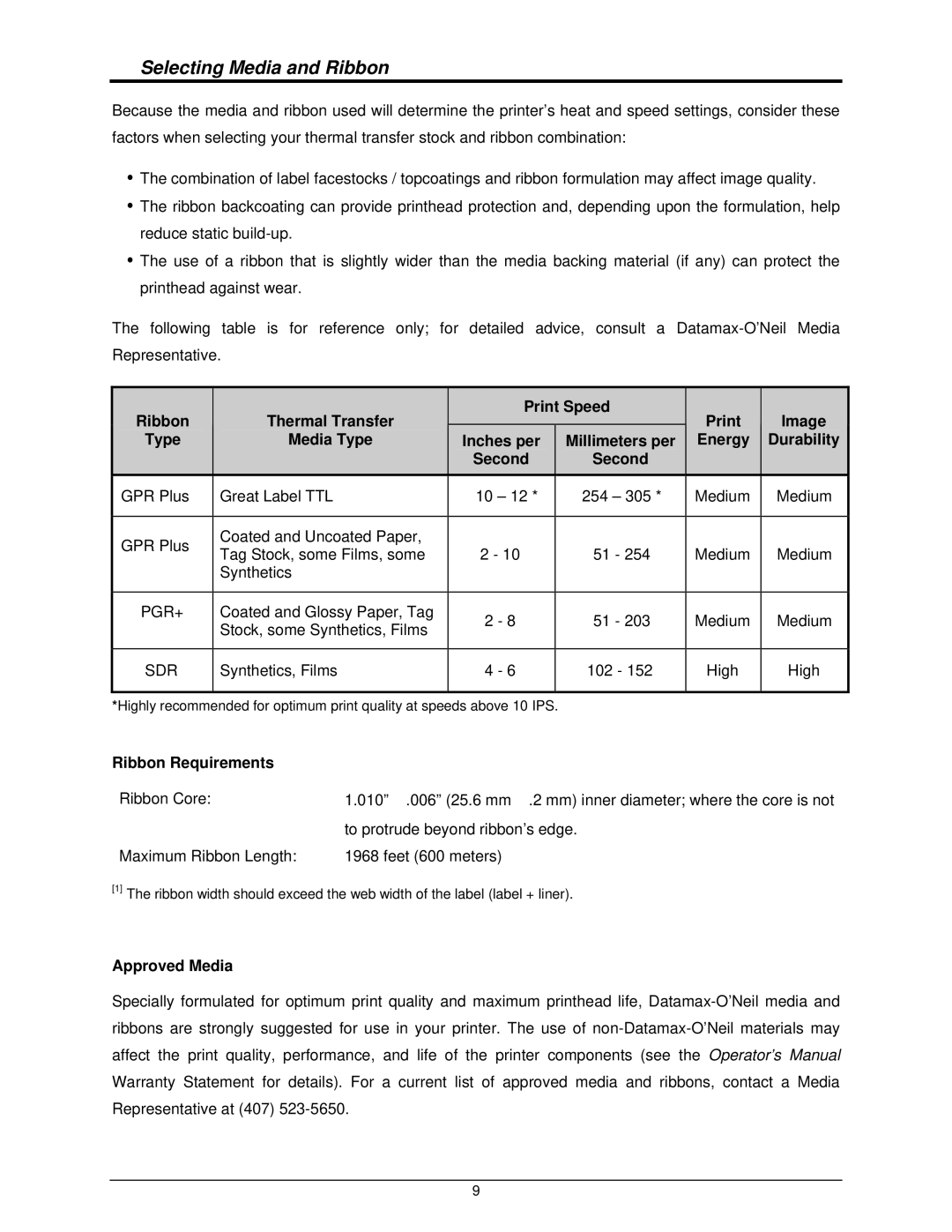

The following table is for reference only; for detailed advice, consult a

| Ribbon |

|

| Thermal Transfer |

|

|

| Print Speed |

| ||||

|

|

|

|

|

|

|

|

|

|

|

| ||

| Type |

|

| Media Type |

|

| Inches per |

|

|

|

|

| |

|

|

|

|

| Millimeters per | ||||||||

|

|

|

|

|

|

| Second |

|

|

| Second |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| GPR Plus | Great Label TTL | 10 | – 12 * |

|

| 254 – 305 * | ||||||

|

|

|

|

|

|

|

|

|

|

|

| ||

| GPR Plus | Coated and Uncoated Paper, |

|

|

|

|

|

|

|

| |||

| Tag Stock, some Films, some | 2 - 10 |

| 51 - 254 |

| ||||||||

|

|

|

|

| |||||||||

|

|

| Synthetics |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| |||

| PGR+ | Coated and Glossy Paper, Tag | 2 | - 8 |

| 51 - 203 |

| ||||||

|

|

| Stock, some Synthetics, Films |

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

| ||||||

| SDR | Synthetics, Films | 4 | - 6 |

| 102 - 152 |

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*Highly recommended for optimum print quality at speeds above 10 IPS.

Image | |

Energy | Durability |

|

|

Medium | Medium |

|

|

Medium | Medium |

|

|

Medium | Medium |

|

|

High | High |

|

|

Ribbon Requirements |

|

Ribbon Core: | 1.010” .006” (25.6 mm .2 mm) inner diameter; where the core is not |

| to protrude beyond ribbon’s edge. |

Maximum Ribbon Length: | 1968 feet (600 meters) |

[1]The ribbon width should exceed the web width of the label (label + liner).

Approved Media

Specially formulated for optimum print quality and maximum printhead life,

9