Media Specifications

Media Specifications

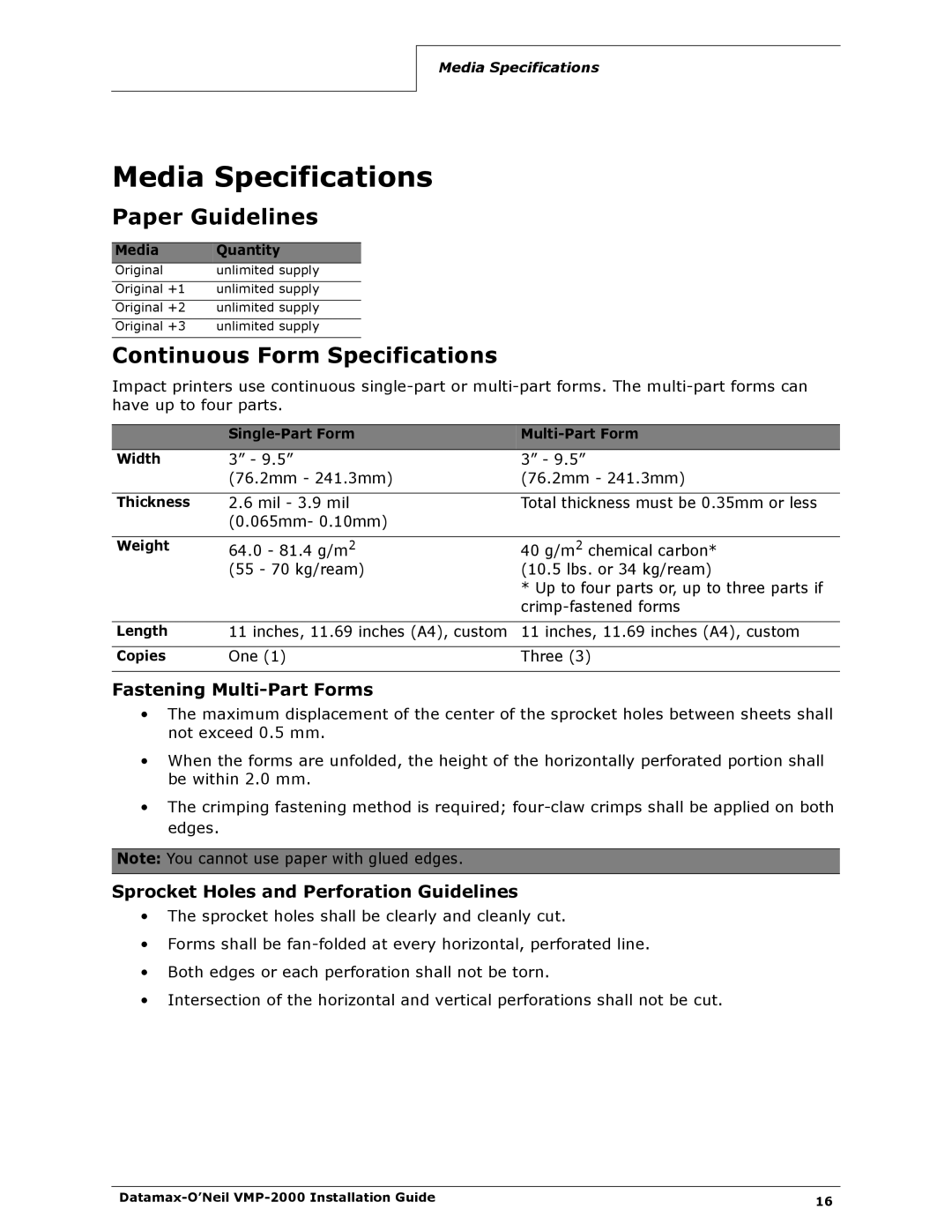

Paper Guidelines

Media | Quantity |

Original | unlimited supply |

Original +1 | unlimited supply |

Original +2 | unlimited supply |

Original +3 | unlimited supply |

Continuous Form Specifications

Impact printers use continuous

| ||

|

|

|

Width | 3” - 9.5” | 3” - 9.5” |

| (76.2mm - 241.3mm) | (76.2mm - 241.3mm) |

|

|

|

Thickness | 2.6 mil - 3.9 mil | Total thickness must be 0.35mm or less |

| (0.065mm- 0.10mm) |

|

|

|

|

Weight | 64.0 - 81.4 g/m2 | 40 g/m2 chemical carbon* |

| (55 - 70 kg/ream) | (10.5 lbs. or 34 kg/ream) |

|

| * Up to four parts or, up to three parts if |

|

| |

|

|

|

Length | 11 inches, 11.69 inches (A4), custom | 11 inches, 11.69 inches (A4), custom |

|

|

|

Copies | One (1) | Three (3) |

Fastening Multi-Part Forms

•The maximum displacement of the center of the sprocket holes between sheets shall not exceed 0.5 mm.

•When the forms are unfolded, the height of the horizontally perforated portion shall be within 2.0 mm.

•The crimping fastening method is required;

Note: You cannot use paper with glued edges.

Sprocket Holes and Perforation Guidelines

•The sprocket holes shall be clearly and cleanly cut.

•Forms shall be

•Both edges or each perforation shall not be torn.

•Intersection of the horizontal and vertical perforations shall not be cut.

16 | |

|