DRILLING HOLES

TO DEPTH

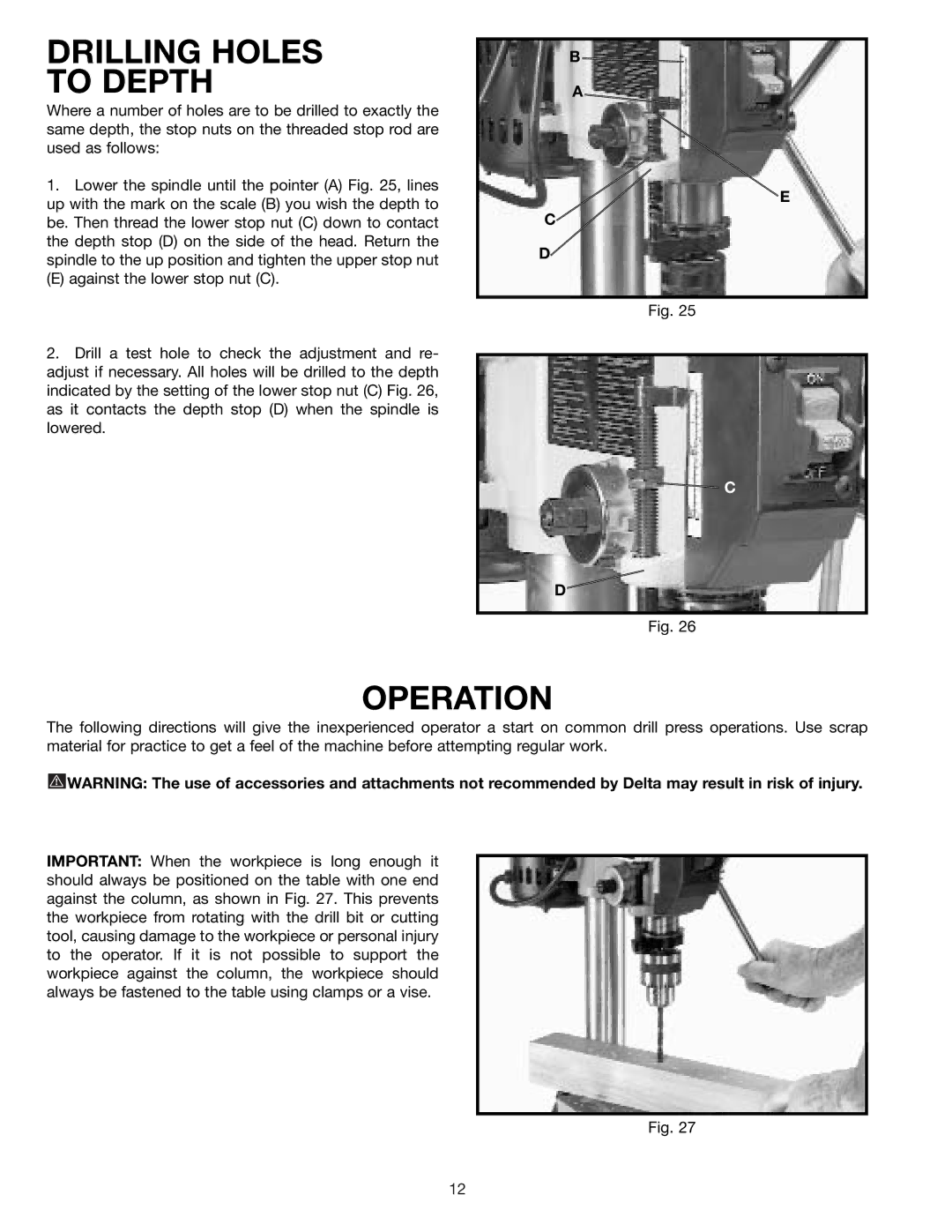

Where a number of holes are to be drilled to exactly the same depth, the stop nuts on the threaded stop rod are used as follows:

1.Lower the spindle until the pointer (A) Fig. 25, lines up with the mark on the scale (B) you wish the depth to be. Then thread the lower stop nut (C) down to contact the depth stop (D) on the side of the head. Return the spindle to the up position and tighten the upper stop nut

(E) against the lower stop nut (C).

2.Drill a test hole to check the adjustment and re- adjust if necessary. All holes will be drilled to the depth indicated by the setting of the lower stop nut (C) Fig. 26, as it contacts the depth stop (D) when the spindle is lowered.

B![]()

A

E

C

D

Fig. 25

![]() C

C

D

Fig. 26

OPERATION

The following directions will give the inexperienced operator a start on common drill press operations. Use scrap material for practice to get a feel of the machine before attempting regular work.

![]() WARNING: The use of accessories and attachments not recommended by Delta may result in risk of injury.

WARNING: The use of accessories and attachments not recommended by Delta may result in risk of injury.

IMPORTANT: When the workpiece is long enough it should always be positioned on the table with one end against the column, as shown in Fig. 27. This prevents the workpiece from rotating with the drill bit or cutting tool, causing damage to the workpiece or personal injury to the operator. If it is not possible to support the workpiece against the column, the workpiece should always be fastened to the table using clamps or a vise.

Fig. 27

12