MAINTENANCE

STARTING AND STOPPING THE SAW

Make sure that the switch is in the "OFF" postion. To reduce the risk of injury, turn unit off and disconnect it from power source

before installing and removing accessories, before adjusting or when making repairs.

An accidental

FAILURE TO START

Should your machine fail to start, check to make sure the prongs on the cord plug are making good contact in the outlet. Also, check for blown fuses or open circuit breakers in the line.

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed air. All plastic parts should be cleaned with a soft damp cloth.

NEVER use solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

![]() Wear certified safety equipment for eye, hearing and respiratory protection while

Wear certified safety equipment for eye, hearing and respiratory protection while

using compressed air

LUBRICATION & RUST PROTECTION

Apply household floor paste wax to the machine table, extension table or other work surface weekly. Or use a commercially available protective product designed for this purpose. Follow the manufacturer’s instructions for use and safety.

To clean cast iron tables of rust, you will need the following materials: a sheet of medium

Degrease the table, then apply the protective product as described above.

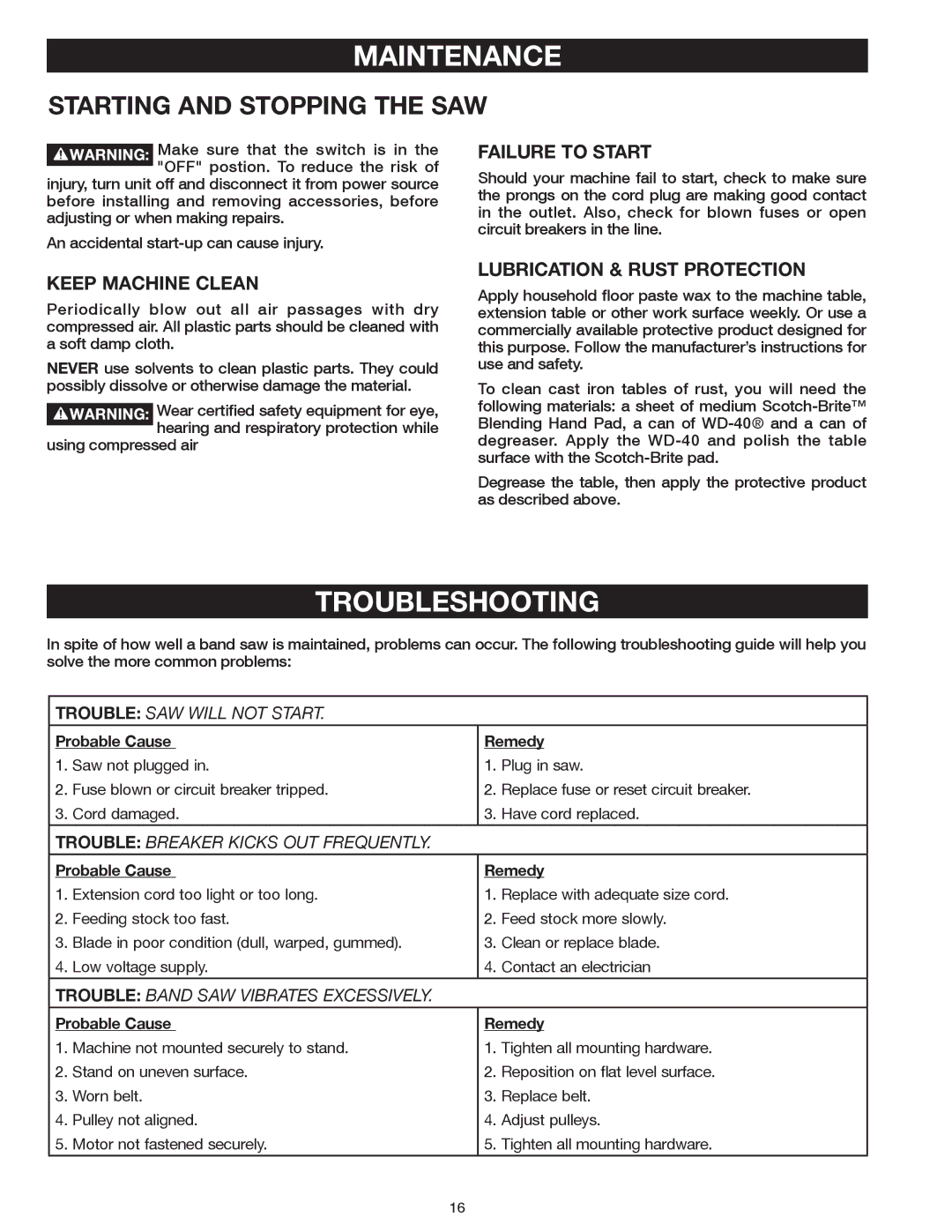

TROUBLESHOOTING

In spite of how well a band saw is maintained, problems can occur. The following troubleshooting guide will help you solve the more common problems:

TROUBLE: SAW WILL NOT START.

Probable Cause | Remedy | ||

1. | Saw not plugged in. | 1. | Plug in saw. |

2. | Fuse blown or circuit breaker tripped. | 2. | Replace fuse or reset circuit breaker. |

3. | Cord damaged. | 3. | Have cord replaced. |

|

|

|

|

TROUBLE: BREAKER KICKS OUT FREQUENTLY.

Probable Cause | Remedy | ||

1. | Extension cord too light or too long. | 1. | Replace with adequate size cord. |

2. | Feeding stock too fast. | 2. | Feed stock more slowly. |

3. | Blade in poor condition (dull, warped, gummed). | 3. | Clean or replace blade. |

4. | Low voltage supply. | 4. | Contact an electrician |

|

|

| |

TROUBLE: BAND SAW VIBRATES EXCESSIVELY. |

|

| |

|

| ||

Probable Cause | Remedy | ||

1. | Machine not mounted securely to stand. | 1. | Tighten all mounting hardware. |

2. | Stand on uneven surface. | 2. | Reposition on flat level surface. |

3. | Worn belt. | 3. | Replace belt. |

4. | Pulley not aligned. | 4. | Adjust pulleys. |

5. | Motor not fastened securely. | 5. | Tighten all mounting hardware. |

|

|

|

|

16