EXTENSION CORDS

Use proper extension cords. Make sure your extension cord is in good condition and is a

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC TOOLS

Ampere |

| Total Length | Gauge of |

Rating | Volts | of Cord in Feet | Extension Cord |

|

|

|

|

120 | up to 25 | 18 AWG | |

120 | 16 AWG | ||

120 | 16 AWG | ||

120 | 14 AWG | ||

120 | up to 25 | 18 AWG | |

120 | 16 AWG | ||

120 | 14 AWG | ||

120 | 12 AWG | ||

|

|

|

|

120 | up to 25 | 16 AWG | |

120 | 16 AWG | ||

120 | 14 AWG | ||

120 | 12 AWG | ||

|

|

|

|

120 | up to 25 | 14 AWG | |

120 | 12 AWG | ||

120 | GREATER THAN 50 FEET NOT RECOMMENDED | ||

|

|

|

|

Fig. 4A

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC TOOLS

Ampere |

| Total Length | Gauge of |

Rating | Volts | of Cord in Feet | Extension Cord |

|

|

|

|

240 | up to 50 | 18 AWG | |

240 | 16 AWG | ||

240 | 16 AWG | ||

240 | 14 AWG | ||

240 | up to 50 | 18 AWG | |

240 | 16 AWG | ||

240 | 14 AWG | ||

240 | 12 AWG | ||

|

|

|

|

240 | up to 50 | 16 AWG | |

240 | 16 AWG | ||

240 | 14 AWG | ||

240 | 12 AWG | ||

|

|

|

|

240 | up to 50 | 14 AWG | |

240 | 12 AWG | ||

240 | GREATER THAN 100 FEET NOT RECOMMENDED | ||

|

|

|

|

Fig. 4B

CHANGING VOLTAGE

The motor supplied with this tool is a dual voltage, 120/240 Volt, Single Phase motor and is wired for 120 volts.

To operate the tool at 240 volts:

1.DISCONNECT TOOL FROM POWER SOURCE.

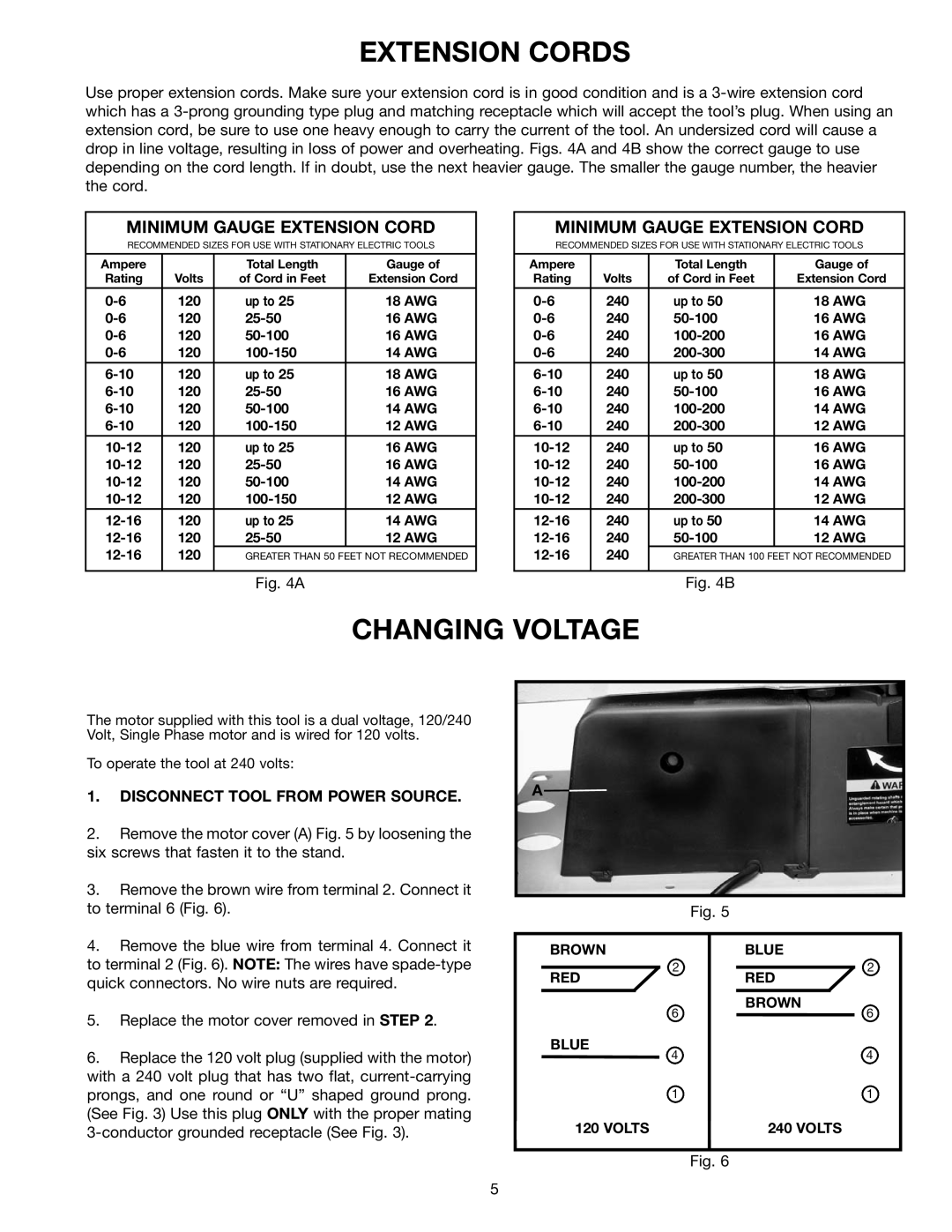

2.Remove the motor cover (A) Fig. 5 by loosening the six screws that fasten it to the stand.

3.Remove the brown wire from terminal 2. Connect it to terminal 6 (Fig. 6).

4.Remove the blue wire from terminal 4. Connect it to terminal 2 (Fig. 6). NOTE: The wires have

5.Replace the motor cover removed in STEP 2.

6.Replace the 120 volt plug (supplied with the motor) with a 240 volt plug that has two flat,

A

| Fig. 5 |

BROWN | BLUE |

2 | 2 |

RED | RED |

6 | BROWN |

6 | |

BLUE | 4 |

4 | |

1 | 1 |

120 VOLTS | 240 VOLTS |

Fig. 6

5