CHECKING BLADE ALIGNMENT

The saw has been aligned at the factory so the saw blade is parallel to the miter gage slots; however, it is recommended to check the alignment before initial operation as follows:

DISCONNECT MACHINE FROM POWER SOURCE.

DISCONNECT MACHINE FROM POWER SOURCE.

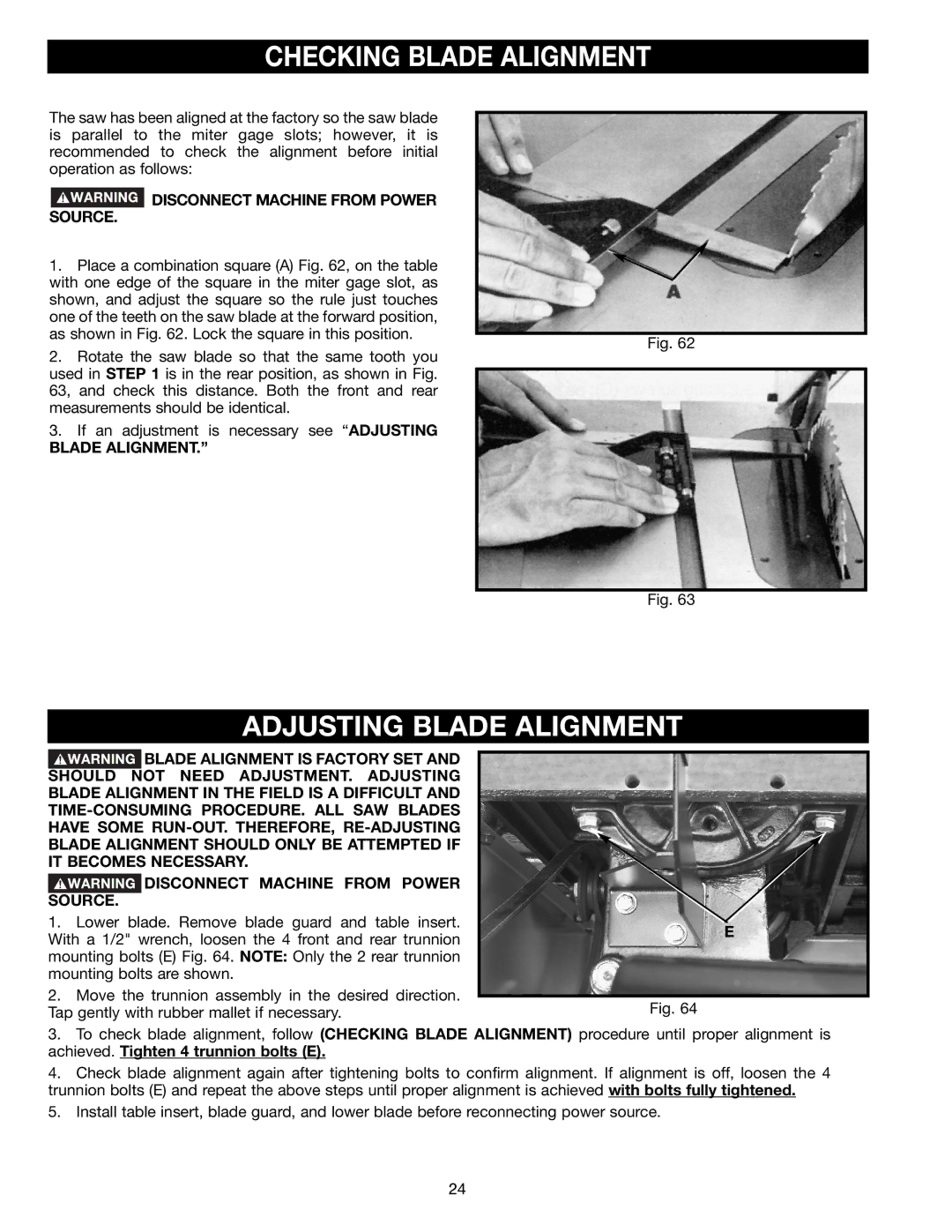

1.Place a combination square (A) Fig. 62, on the table with one edge of the square in the miter gage slot, as shown, and adjust the square so the rule just touches one of the teeth on the saw blade at the forward position, as shown in Fig. 62. Lock the square in this position.

2.Rotate the saw blade so that the same tooth you used in STEP 1 is in the rear position, as shown in Fig. 63, and check this distance. Both the front and rear measurements should be identical.

3.If an adjustment is necessary see “ADJUSTING

BLADE ALIGNMENT.”

Fig. 62

Fig. 63

ADJUSTING BLADE ALIGNMENT

![]() BLADE ALIGNMENT IS FACTORY SET AND SHOULD NOT NEED ADJUSTMENT. ADJUSTING BLADE ALIGNMENT IN THE FIELD IS A DIFFICULT AND

BLADE ALIGNMENT IS FACTORY SET AND SHOULD NOT NEED ADJUSTMENT. ADJUSTING BLADE ALIGNMENT IN THE FIELD IS A DIFFICULT AND

DISCONNECT MACHINE FROM POWER

SOURCE.

1.Lower blade. Remove blade guard and table insert. With a 1/2" wrench, loosen the 4 front and rear trunnion mounting bolts (E) Fig. 64. NOTE: Only the 2 rear trunnion mounting bolts are shown.

2.Move the trunnion assembly in the desired direction. Tap gently with rubber mallet if necessary.

E

Fig. 64

3.To check blade alignment, follow (CHECKING BLADE ALIGNMENT) procedure until proper alignment is achieved. Tighten 4 trunnion bolts (E).

4.Check blade alignment again after tightening bolts to confirm alignment. If alignment is off, loosen the 4 trunnion bolts (E) and repeat the above steps until proper alignment is achieved with bolts fully tightened.

5.Install table insert, blade guard, and lower blade before reconnecting power source.

24