ASSEMBLING DUST INTAKE HOSES TO BLOWER AND MOTOR ASSEMBLY

KEEP DUST CAPS INSTALLED AT ALL TIMES OVER INTAKE PORTS. REMOVE A DUST CAP ONLY WHEN A FLEXIBLE HOSE IS ATTACHED TO THE INTAKE PORT.

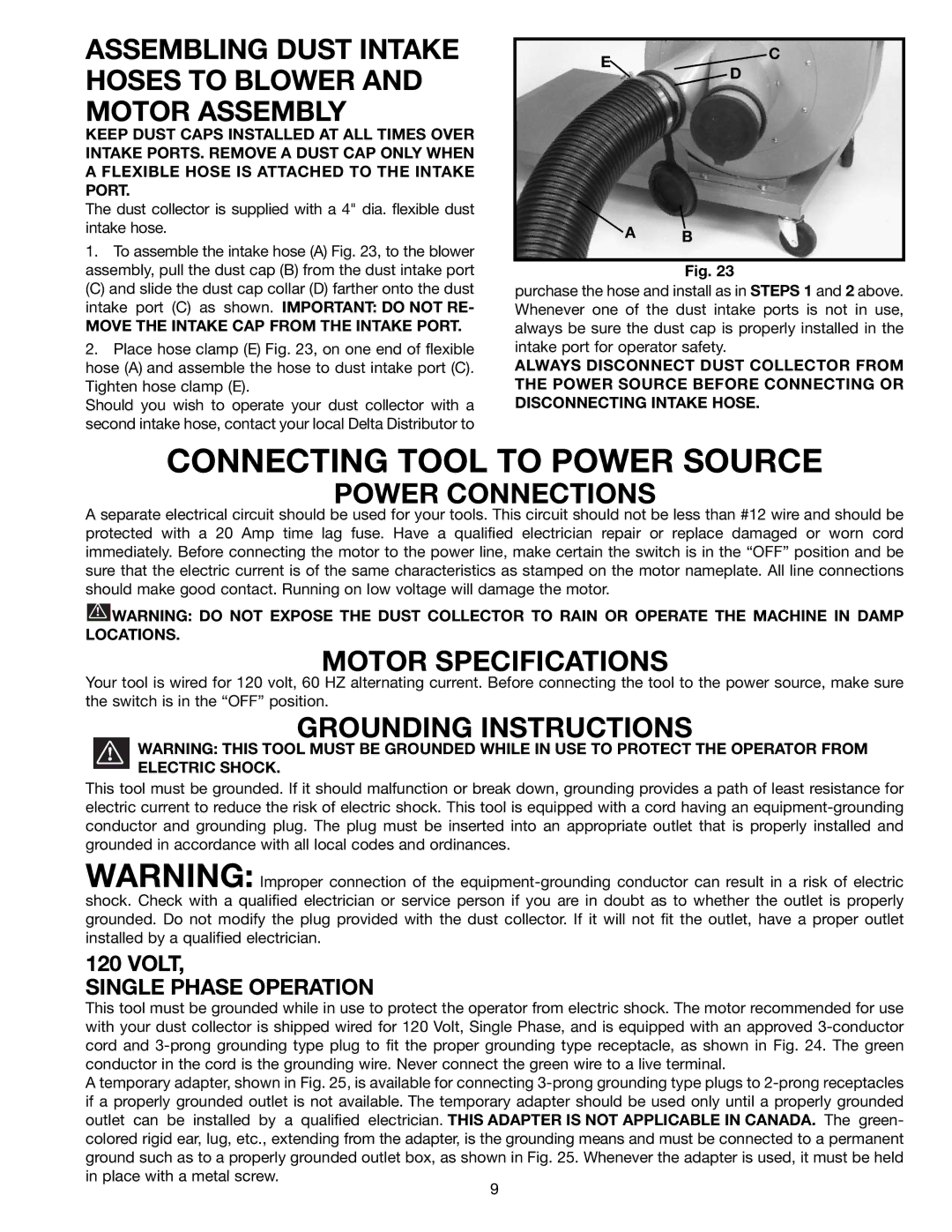

The dust collector is supplied with a 4" dia. flexible dust intake hose.

1.To assemble the intake hose (A) Fig. 23, to the blower assembly, pull the dust cap (B) from the dust intake port

(C) and slide the dust cap collar (D) farther onto the dust intake port (C) as shown. IMPORTANT: DO NOT RE-

MOVE THE INTAKE CAP FROM THE INTAKE PORT.

2.Place hose clamp (E) Fig. 23, on one end of flexible hose (A) and assemble the hose to dust intake port (C). Tighten hose clamp (E).

Should you wish to operate your dust collector with a second intake hose, contact your local Delta Distributor to

EC

D

A B

Fig. 23

purchase the hose and install as in STEPS 1 and 2 above. Whenever one of the dust intake ports is not in use, always be sure the dust cap is properly installed in the intake port for operator safety.

ALWAYS DISCONNECT DUST COLLECTOR FROM THE POWER SOURCE BEFORE CONNECTING OR DISCONNECTING INTAKE HOSE.

CONNECTING TOOL TO POWER SOURCE

POWER CONNECTIONS

A separate electrical circuit should be used for your tools. This circuit should not be less than #12 wire and should be protected with a 20 Amp time lag fuse. Have a qualified electrician repair or replace damaged or worn cord immediately. Before connecting the motor to the power line, make certain the switch is in the “OFF” position and be sure that the electric current is of the same characteristics as stamped on the motor nameplate. All line connections should make good contact. Running on low voltage will damage the motor.

![]() WARNING: DO NOT EXPOSE THE DUST COLLECTOR TO RAIN OR OPERATE THE MACHINE IN DAMP LOCATIONS.

WARNING: DO NOT EXPOSE THE DUST COLLECTOR TO RAIN OR OPERATE THE MACHINE IN DAMP LOCATIONS.

MOTOR SPECIFICATIONS

Your tool is wired for 120 volt, 60 HZ alternating current. Before connecting the tool to the power source, make sure the switch is in the “OFF” position.

GROUNDING INSTRUCTIONS

WARNING: THIS TOOL MUST BE GROUNDED WHILE IN USE TO PROTECT THE OPERATOR FROM ELECTRIC SHOCK.

This tool must be grounded. If it should malfunction or break down, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This tool is equipped with a cord having an

WARNING: Improper connection of the

120 VOLT,

SINGLE PHASE OPERATION

This tool must be grounded while in use to protect the operator from electric shock. The motor recommended for use with your dust collector is shipped wired for 120 Volt, Single Phase, and is equipped with an approved

A temporary adapter, shown in Fig. 25, is available for connecting

9