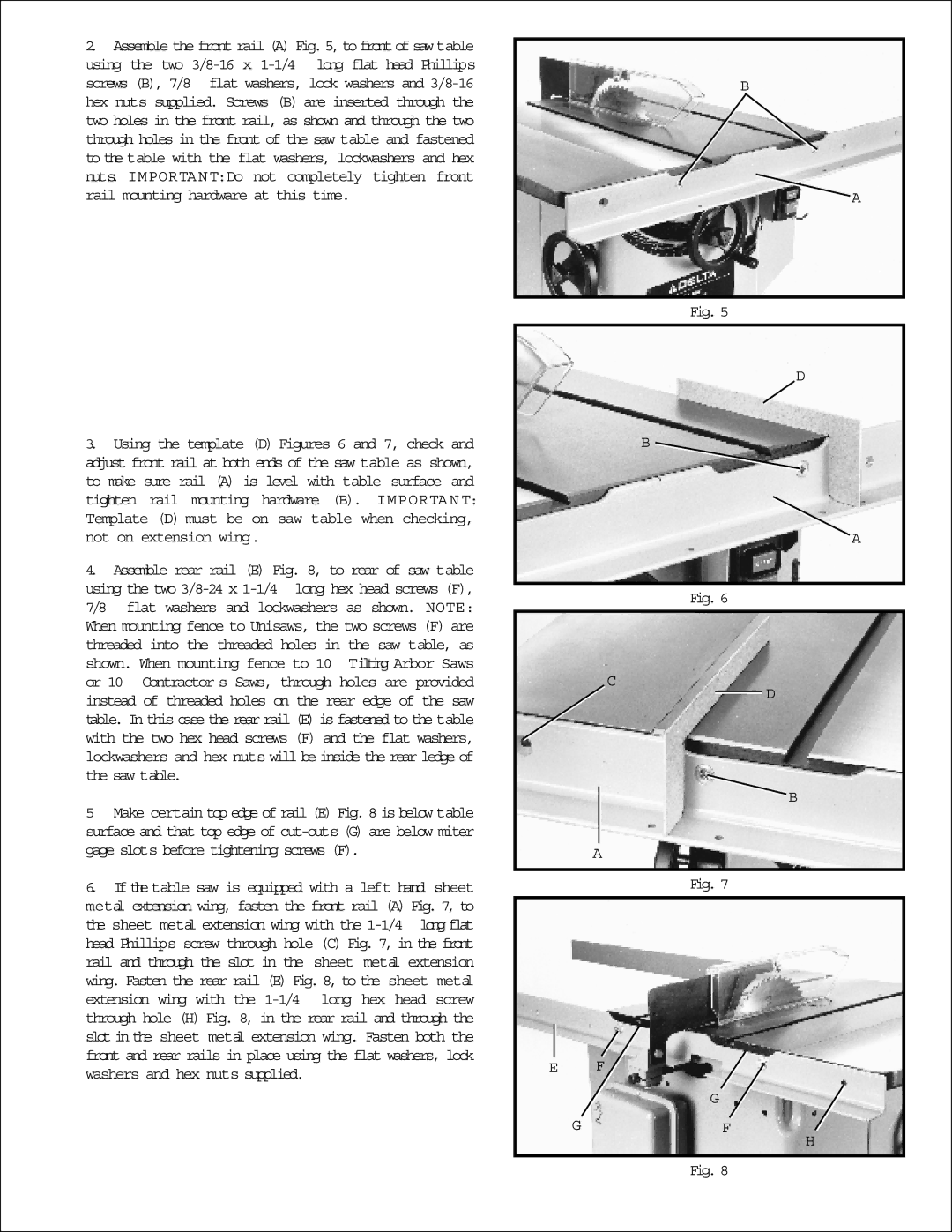

2. Assemble the front rail (A) Fig. 5, to front of saw table using the two 3/8-16 x 1-1/4 long flat head Phillips screws (B), 7/8 flat washers, lock washers and 3/8-16 hex nuts supplied. Screws (B) are inserted through the two holes in the front rail, as shown and through the two through holes in the front of the saw table and fastened to the table with the flat washers, lockwashers and hex nuts. IMPORTANT:Do not completely tighten front rail mounting hardware at this time.

3.Using the template (D) Figures 6 and 7, check and adjust front rail at both ends of the saw table as shown, to make sure rail (A) is level with table surface and tighten rail mounting hardware (B). IMPORTANT: Template (D) must be on saw table when checking, not on extension wing.

4.Assemble rear rail (E) Fig. 8, to rear of saw table

using the two 3/8-24 x 1-1/4 long hex head screws (F), 7/8 flat washers and lockwashers as shown. NOTE: When mounting fence to Unisaws, the two screws (F) are threaded into the threaded holes in the saw table, as shown. When mounting fence to 10 Tilting Arbor Saws or 10 Contractor s Saws, through holes are provided instead of threaded holes on the rear edge of the saw table. In this case the rear rail (E) is fastened to the table with the two hex head screws (F) and the flat washers, lockwashers and hex nuts will be inside the rear ledge of the saw table.

5Make certain top edge of rail (E) Fig. 8 is below table surface and that top edge of cut-outs (G) are below miter gage slots before tightening screws (F).

6.If the table saw is equipped with a left hand sheet metal extension wing, fasten the front rail (A) Fig. 7, to

the sheet metal extension wing with the 1-1/4 long flat head Phillips screw through hole (C) Fig. 7, in the front rail and through the slot in the sheet metal extension wing. Fasten the rear rail (E) Fig. 8, to the sheet metal extension wing with the 1-1/4 long hex head screw through hole (H) Fig. 8, in the rear rail and through the slot in the sheet metal extension wing. Fasten both the front and rear rails in place using the flat washers, lock washers and hex nuts supplied.

![]() A

A