INSTALLATION

Continued

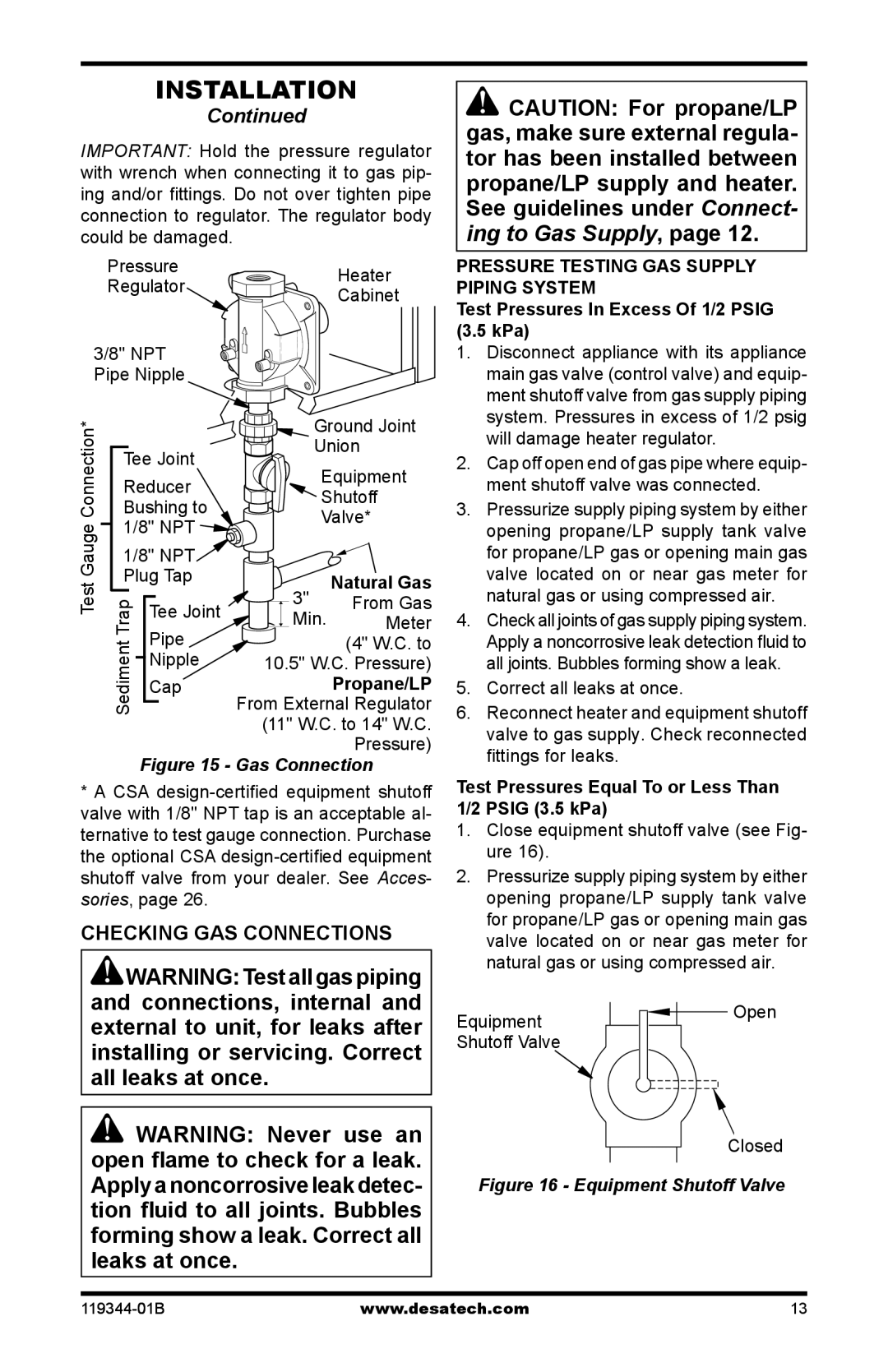

IMPORTANT: Hold the pressure regulator with wrench when connecting it to gas pip- ing and/or fittings. Do not over tighten pipe connection to regulator. The regulator body could be damaged.

| Pressure |

| Heater | ||

| Regulator |

| |||

|

| Cabinet | |||

|

|

|

| ||

| 3/8" NPT |

|

| ||

| Pipe Nipple |

|

| ||

Connection* | Bushing to | Ground Joint | |||

Union | |||||

| Tee Joint | ||||

| Equipment | ||||

| Reducer | ||||

| Shutoff | ||||

|

|

| |||

Gauge | 1/8" NPT | Valve* | |||

|

| ||||

1/8" NPT |

|

| |||

|

|

| |||

Test | Plug Tap |

| Natural Gas | ||

Trap |

| 3" | |||

Tee Joint | From Gas | ||||

|

| Min. | Meter | ||

|

| Pipe | |||

| Sediment |

| (4" W.C. to | ||

| Nipple | 10.5" W.C. Pressure) | |||

|

| ||||

|

| Cap |

| Propane/LP | |

|

|

| From External Regulator | ||

|

|

| (11" W.C. to 14" W.C. | ||

|

|

|

| Pressure) | |

|

| Figure 15 - Gas Connection | |||

*A CSA

CHECKING GAS CONNECTIONS

![]() WARNING: Test all gas piping and connections, internal and external to unit, for leaks after installing or servicing. Correct all leaks at once.

WARNING: Test all gas piping and connections, internal and external to unit, for leaks after installing or servicing. Correct all leaks at once.

![]() WARNING: Never use an open flame to check for a leak. Apply a noncorrosive leak detec- tion fluid to all joints. Bubbles forming show a leak. Correct all leaks at once.

WARNING: Never use an open flame to check for a leak. Apply a noncorrosive leak detec- tion fluid to all joints. Bubbles forming show a leak. Correct all leaks at once.

![]() CAUTION: For propane/LP gas, make sure external regula- tor has been installed between propane/LP supply and heater. See guidelines under Connect- ing to Gas Supply, page 12.

CAUTION: For propane/LP gas, make sure external regula- tor has been installed between propane/LP supply and heater. See guidelines under Connect- ing to Gas Supply, page 12.

Pressure Testing Gas Supply Piping System

Test Pressures In Excess Of 1/2 PSIG (3.5 kPa)

1.Disconnect appliance with its appliance main gas valve (control valve) and equip- ment shutoff valve from gas supply piping system. Pressures in excess of 1/2 psig will damage heater regulator.

2.Cap off open end of gas pipe where equip- ment shutoff valve was connected.

3.Pressurize supply piping system by either opening propane/LP supply tank valve for propane/LP gas or opening main gas valve located on or near gas meter for natural gas or using compressed air.

4.Check all joints of gas supply piping system. Apply a noncorrosive leak detection fluid to all joints. Bubbles forming show a leak.

5.Correct all leaks at once.

6.Reconnect heater and equipment shutoff valve to gas supply. Check reconnected fittings for leaks.

Test Pressures Equal To or Less Than 1/2 PSIG (3.5 kPa)

1.Close equipment shutoff valve (see Fig- ure 16).

2.Pressurize supply piping system by either opening propane/LP supply tank valve for propane/LP gas or opening main gas valve located on or near gas meter for natural gas or using compressed air.

Equipment | Open |

| |

Shutoff Valve |

|

| Closed |

Figure 16 - Equipment Shutoff Valve

www.desatech.com | 13 |