MAINTENANCE (cont'd)

Nozzle cleaning:

If the nozzle becomes clogged with foreign materials, such as dirt, excessive pressure may develop. If the nozzle becomes partially clogged or restricted, the pump pressure will pulsate. Clean the nozzle immediately using the nozzle kit supplied and the following instructions:

Multi-Reg Wand/Lance:

1.Shut off the pressure washer and turn off the water supply.

2.Disconnect spark plug wire.

3.Pull trigger on gun handle to relieve any water pressure.

4.Disconnect the wand/lance from the gun.

5.Remove the nozzle from the end of the wand with the 2mm allen wrench provided as shown in Figure 16.

6.Clean the nozzle using the nozzle cleaner provided or a straightened paper clip. Insert into the nozzle end and work back and forth until obstruction is removed. See Figure 17.

7.Direct water supply into nozzle end to backflush loosened particles for 30 seconds. See Figure 18.

8.Reassemble the nozzle to the wand. Tighten securely to prevent leaks.

9.Reconnect wand/lance to gun and turn on water supply.

10.Start pressure washer and place wand/lance into high pressure setting to test.

Figure 16

Figure 17

Figure 18

Dual Lance/Hi-Low Lance/Quick Connect Lance:

1.Shut off the pressure washer and turn off the water supply.

2.Disconnect spark plug wire.

3.Pull trigger on gun handle to relieve any water pressure.

4.Disconnect the wand/lance from the gun.

5.Remove the

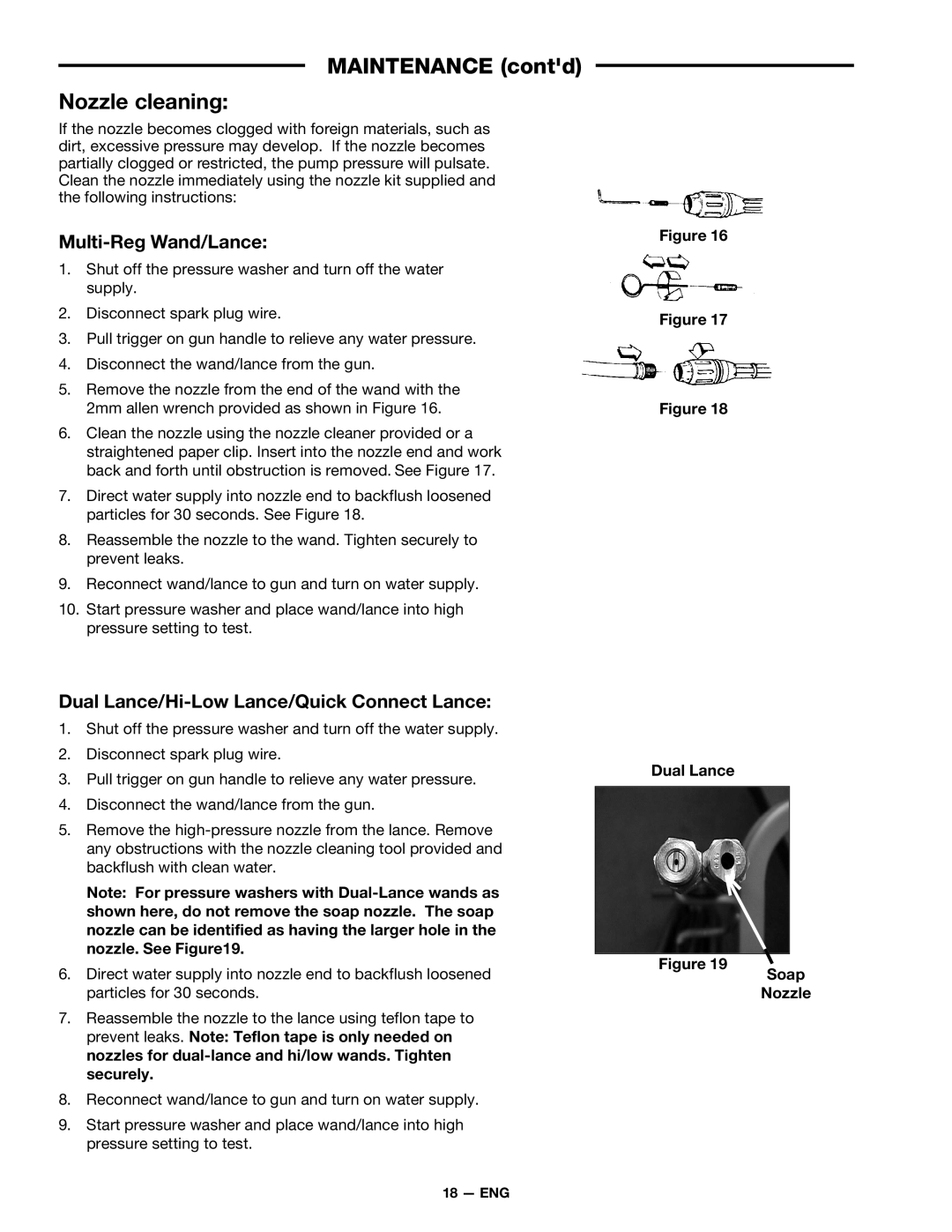

Note: For pressure washers with

6.Direct water supply into nozzle end to backflush loosened particles for 30 seconds.

7.Reassemble the nozzle to the lance using teflon tape to prevent leaks. Note: Teflon tape is only needed on nozzles for

8.Reconnect wand/lance to gun and turn on water supply.

9.Start pressure washer and place wand/lance into high pressure setting to test.

Dual Lance

Figure 19

Soap

Nozzle

18 — ENG