INSTALLATION AND BREAK-IN PROCEDURES

Location of the Air Compressor

Locate the air compressor in a clean, dry and well ventilated area. The air filter must be kept clear of obstructions which could reduce air flow to the air compressor. The air compres- sor should be located at least 12" away from the wall or other obstructions that will interfere with the flow of air. The air compressor head and shroud are designed to allow for proper cooling. If humidity is high, an air filter can be installed on the air outlet adapter to remove excessive moisture. Follow the instructions packaged with the air filter for proper installation.

Certain air compressor models can be converted to 240 volts from 120 volt operation. When con- verting a specific model to 240 volt operation, the attached

Refer to Parts List of your compressor. Certain air compressor models can be operated on a 15 amp circuit if:

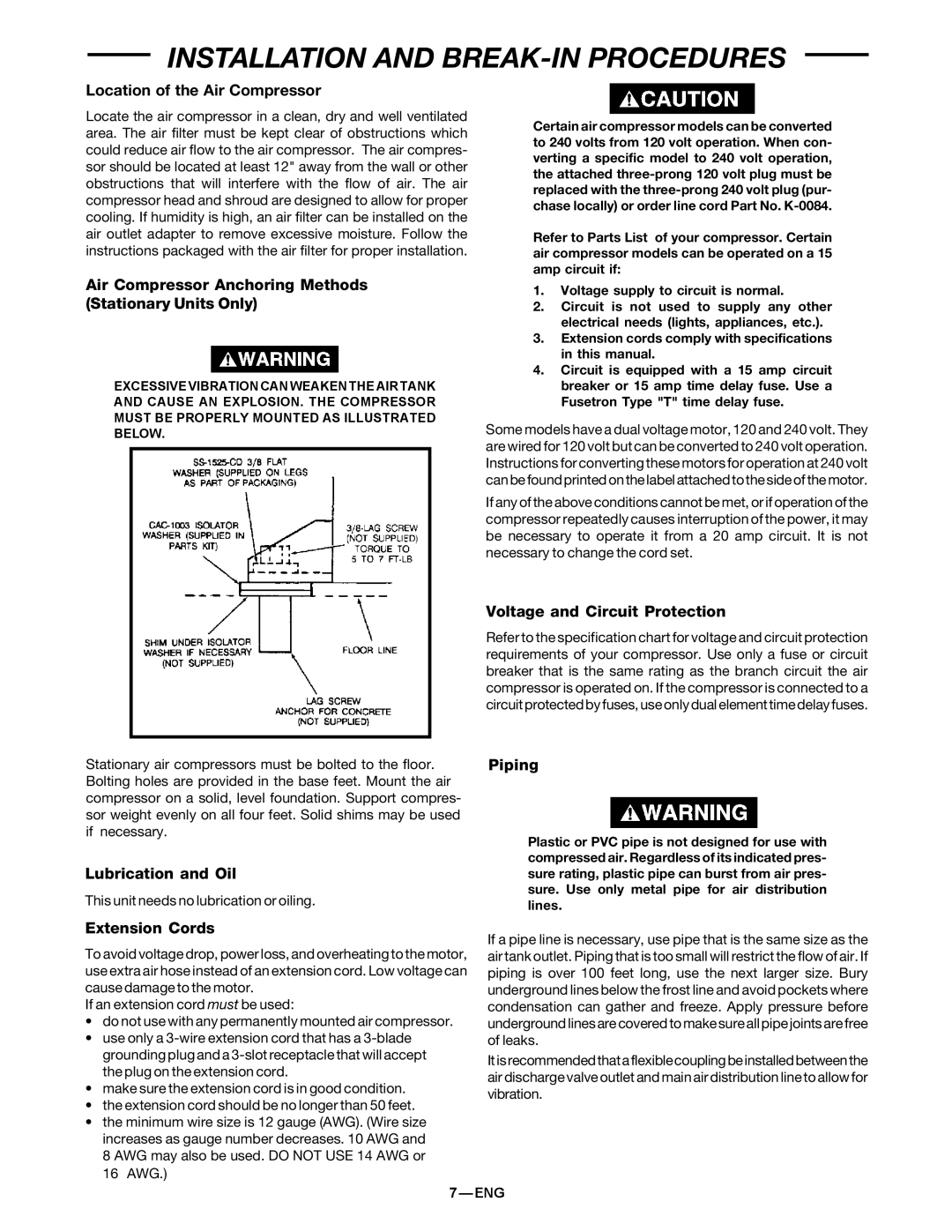

Air Compressor Anchoring Methods (Stationary Units Only)

EXCESSIVEVIBRATIONCANWEAKENTHEAIRTANK AND CAUSE AN EXPLOSION. THE COMPRESSOR MUST BE PROPERLY MOUNTED AS ILLUSTRATED BELOW.

1.Voltage supply to circuit is normal.

2.Circuit is not used to supply any other electrical needs (lights, appliances, etc.).

3.Extension cords comply with specifications in this manual.

4.Circuit is equipped with a 15 amp circuit breaker or 15 amp time delay fuse. Use a Fusetron Type "T" time delay fuse.

Some models have a dual voltage motor, 120 and 240 volt. They are wired for 120 volt but can be converted to 240 volt operation. Instructions for converting these motors for operation at 240 volt can be found printed on the label attached to the side of the motor.

If any of the above conditions cannot be met, or if operation of the compressor repeatedly causes interruption of the power, it may be necessary to operate it from a 20 amp circuit. It is not necessary to change the cord set.

Stationary air compressors must be bolted to the floor. Bolting holes are provided in the base feet. Mount the air compressor on a solid, level foundation. Support compres- sor weight evenly on all four feet. Solid shims may be used if necessary.

Lubrication and Oil

This unit needs no lubrication or oiling.

Voltage and Circuit Protection

Refer to the specification chart for voltage and circuit protection requirements of your compressor. Use only a fuse or circuit breaker that is the same rating as the branch circuit the air compressor is operated on. If the compressor is connected to a circuit protected by fuses, use only dual element time delay fuses.

Piping

Plastic or PVC pipe is not designed for use with compressed air. Regardless of its indicated pres- sure rating, plastic pipe can burst from air pres- sure. Use only metal pipe for air distribution lines.

Extension Cords

To avoid voltage drop, power loss, and overheating to the motor, use extra air hose instead of an extension cord. Low voltage can cause damage to the motor.

If an extension cord must be used:

•do not use with any permanently mounted air compressor.

•use only a

•make sure the extension cord is in good condition.

•the extension cord should be no longer than 50 feet.

•the minimum wire size is 12 gauge (AWG). (Wire size increases as gauge number decreases. 10 AWG and 8 AWG may also be used. DO NOT USE 14 AWG or 16 AWG.)

If a pipe line is necessary, use pipe that is the same size as the air tank outlet. Piping that is too small will restrict the flow of air. If piping is over 100 feet long, use the next larger size. Bury underground lines below the frost line and avoid pockets where condensation can gather and freeze. Apply pressure before underground lines are covered to make sure all pipe joints are free of leaks.

Itisrecommendedthataflexiblecouplingbeinstalledbetweenthe air discharge valve outlet and main air distribution line to allow for vibration.