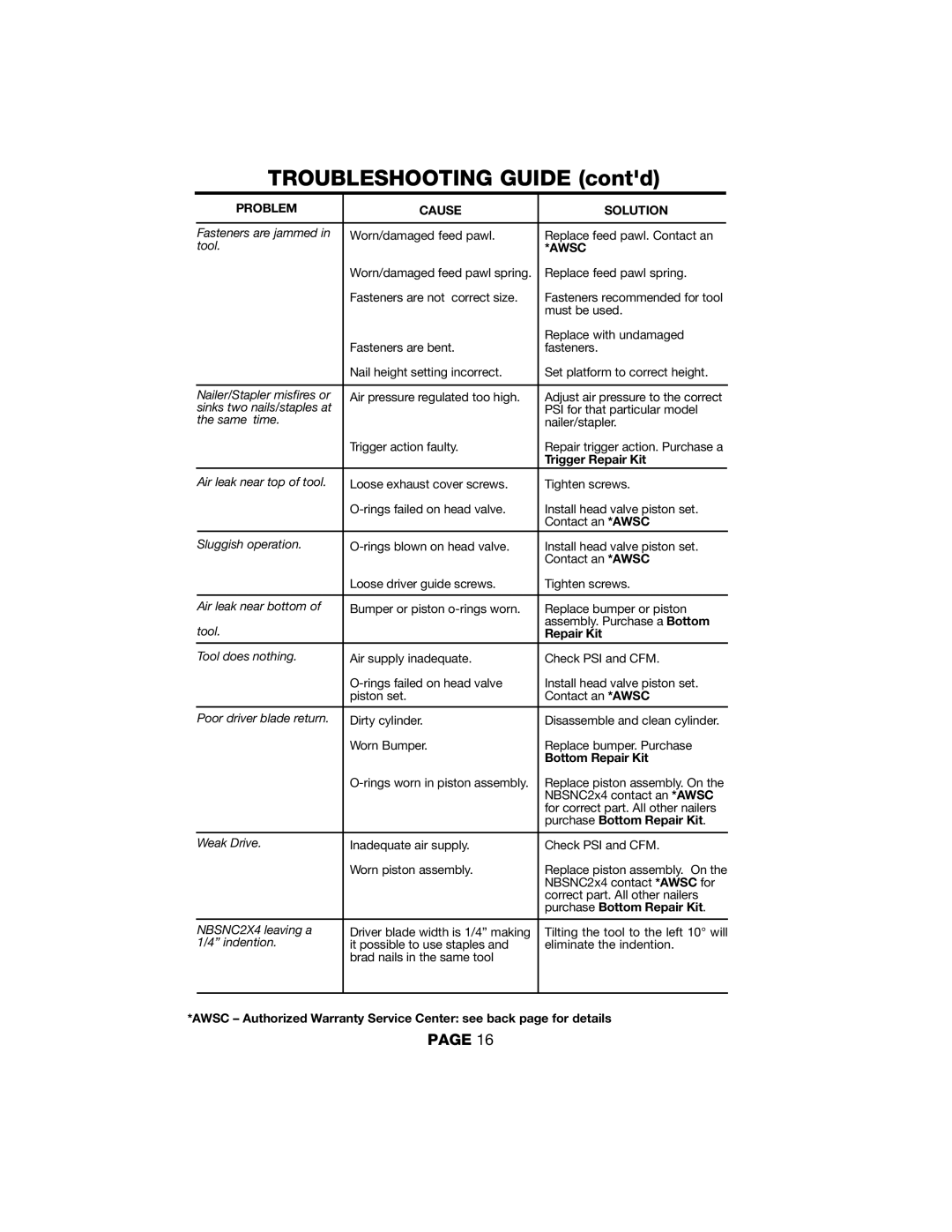

TROUBLESHOOTING GUIDE (cont'd)

| PROBLEM | CAUSE | SOLUTION |

|

|

|

|

|

|

| Fasteners are jammed in | Worn/damaged feed pawl. | Replace feed pawl. Contact an | |

| tool. |

| *AWSC | |

|

| Worn/damaged feed pawl spring. | Replace feed pawl spring. | |

|

| Fasteners are not correct size. | Fasteners recommended for tool | |

|

|

| must be used. | |

|

| Fasteners are bent. | Replace with undamaged | |

|

| fasteners. | ||

|

| Nail height setting incorrect. | Set platform to correct height. | |

|

|

|

|

|

| Nailer/Stapler misfires or | Air pressure regulated too high. | Adjust air pressure to the correct | |

| sinks two nails/staples at |

| PSI for that particular model | |

| the same time. |

| nailer/stapler. | |

|

| Trigger action faulty. | Repair trigger action. Purchase a | |

|

|

| Trigger Repair Kit | |

| Air leak near top of tool. | Loose exhaust cover screws. | Tighten screws. | |

|

| Install head valve piston set. | ||

|

|

| Contact an *AWSC | |

| Sluggish operation. | Install head valve piston set. | ||

|

|

| Contact an *AWSC | |

|

| Loose driver guide screws. | Tighten screws. | |

|

|

|

| |

| Air leak near bottom of | Bumper or piston | Replace bumper or piston | |

| tool. |

| assembly. Purchase a Bottom | |

|

| Repair Kit | ||

| Tool does nothing. | Air supply inadequate. | Check PSI and CFM. | |

|

| Install head valve piston set. | ||

|

| piston set. | Contact an *AWSC | |

|

|

|

| |

| Poor driver blade return. | Dirty cylinder. | Disassemble and clean cylinder. | |

|

| Worn Bumper. | Replace bumper. Purchase | |

|

|

| Bottom Repair Kit | |

|

| Replace piston assembly. On the | ||

|

|

| NBSNC2x4 contact an *AWSC | |

|

|

| for correct part. All other nailers | |

|

|

| purchase Bottom Repair Kit. | |

|

|

|

| |

| Weak Drive. | Inadequate air supply. | Check PSI and CFM. | |

|

| Worn piston assembly. | Replace piston assembly. On the | |

|

|

| NBSNC2x4 contact *AWSC for | |

|

|

| correct part. All other nailers | |

|

|

| purchase Bottom Repair Kit. | |

|

|

|

| |

| NBSNC2X4 leaving a | Driver blade width is 1/4” making | Tilting the tool to the left 10° will | |

| 1/4” indention. | it possible to use staples and | eliminate the indention. | |

|

| brad nails in the same tool |

|

|

|

|

|

|

|

*AWSC – Authorized Warranty Service Center: see back page for details

PAGE 16