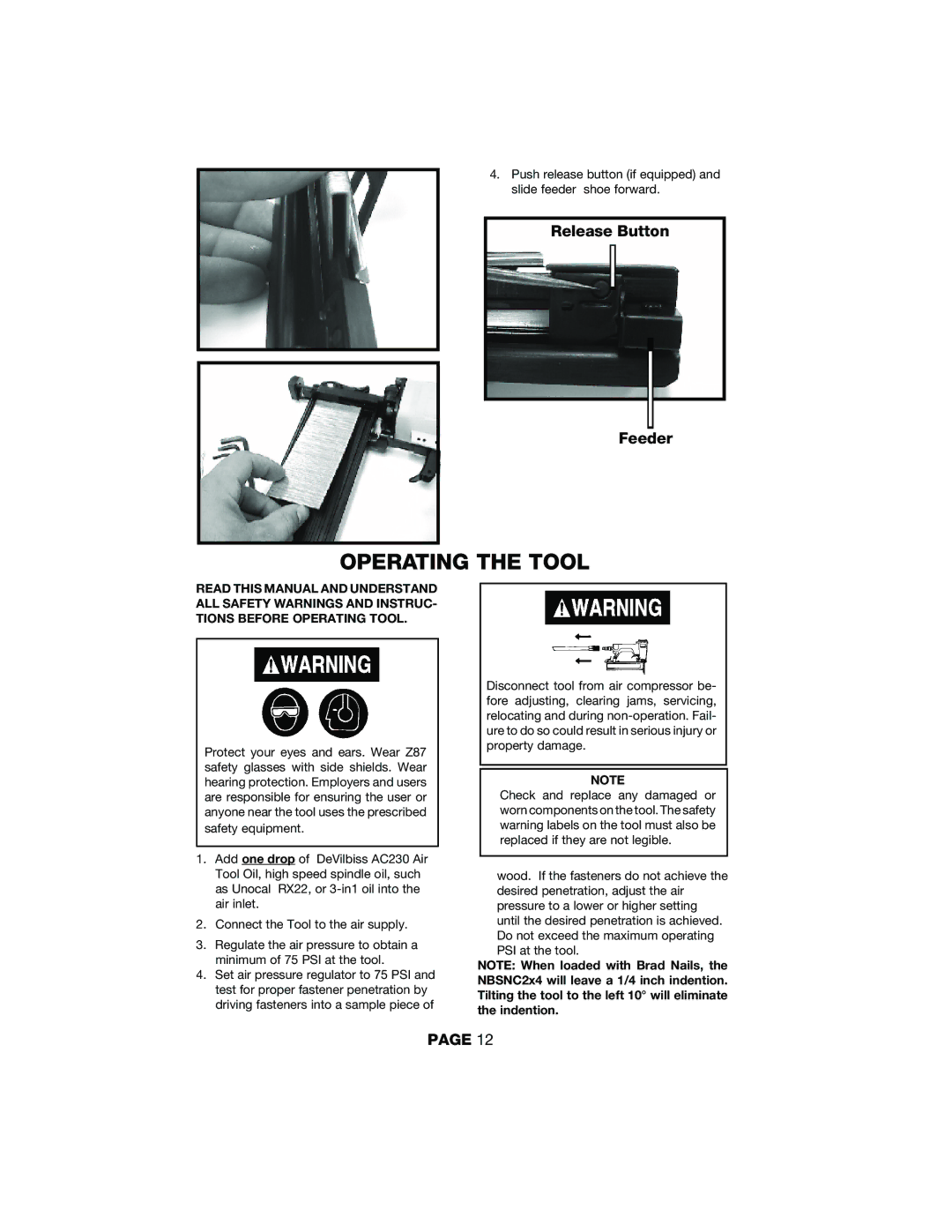

4.Push release button (if equipped) and slide feeder shoe forward.

Release Button

Feeder

OPERATING THE TOOL

READ THIS MANUAL AND UNDERSTAND ALL SAFETY WARNINGS AND INSTRUC- TIONS BEFORE OPERATING TOOL.

Protect your eyes and ears. Wear Z87 safety glasses with side shields. Wear hearing protection. Employers and users are responsible for ensuring the user or anyone near the tool uses the prescribed safety equipment.

1.Add one drop of DeVilbiss AC230 Air Tool Oil, high speed spindle oil, such as Unocal RX22, or

2.Connect the Tool to the air supply.

3.Regulate the air pressure to obtain a minimum of 75 PSI at the tool.

4.Set air pressure regulator to 75 PSI and test for proper fastener penetration by driving fasteners into a sample piece of

Disconnect tool from air compressor be- fore adjusting, clearing jams, servicing, relocating and during

NOTE

Check and replace any damaged or worn components on the tool. The safety warning labels on the tool must also be replaced if they are not legible.

wood. If the fasteners do not achieve the desired penetration, adjust the air pressure to a lower or higher setting until the desired penetration is achieved. Do not exceed the maximum operating PSI at the tool.

NOTE: When loaded with Brad Nails, the NBSNC2x4 will leave a 1/4 inch indention. Tilting the tool to the left 10° will eliminate the indention.

PAGE 12