FIG. 1

C

B

A

DC727

FIG. 2

E

D

E

FIG. 3

instructions before of chargers and

not probe with

continuously

continuously. The

battery packs. battery pack the charger is be returned elicits the same

center.

battery that is has cooled.

Charging mode. then short while in the Hot

have a Problem Power Line indicator. When the charger is used with some power sources such as generators or sources that convert DC to AC, the charger may temporarily suspend operation, flashing the red light with two fast blinks followed by a pause.

This indicates the power source is out of limits.

LEAVING THE BATTERY PACK IN THE CHARGER

The charger and battery pack can be left connected with the red light glowing indefinitely. The charger will keep the battery pack fresh and fully charged.

NOTE: A battery pack will slowly lose its charge when kept out of the charger. If the battery pack has not been kept on maintenance charge, it may need to be recharged before use. A battery pack may also slowly lose its charge if left in a charger that is not plugged into an appropriate AC source.

WEAK BATTERY PACKS: Chargers can also detect a weak battery pack. Such batteries are still usable but should not be expected to perform as much work. The charger will indicate to replace battery pack.

Important Charging Notes

1.Longest life and best performance can be obtained if the battery pack is charged when the air temperature is between 65°F and 75°F (18°- 24°C). DO NOT charge the battery pack in an air temperature below +40°F (+4.5°C), or above +105°F (+40.5°C). This is important and will prevent serious damage to the battery pack.

2.The charger and battery pack may become warm to touch while charging. This is a normal condition, and does not indicate a problem. To facilitate the cooling of the battery pack after use, avoid placing the charger or battery pack in a warm environment such as in a metal shed, or an uninsulated trailer.

3.If the battery pack does not charge properly:

a.Check current at receptacle by plugging in a lamp or other appliance

b.Check to see if receptacle is connected to a light switch which turns power off when you turn out the lights.

c.Move charger and battery pack to a location where the surrounding air temperature is approximately 65°F - 75°F (18°- 24°C).

d.If charging problems persist, take the tool, battery pack and charger to your local service center.

4.The battery pack should be recharged when it fails to produce sufficient power on jobs which were easily done previously. DO NOT CONTINUE to use under these conditions. Follow the charging procedure. You may also charge a partially used pack whenever you desire with no adverse affect on the battery pack.

5.Under certain conditions, with the charger plugged into the power supply, the exposed charging contacts inside the charger can be shorted by foreign material. Foreign materials of a conductive nature such as, but not limited to, steel wool, aluminum foil, or any buildup of metallic particles should be kept away from charger cavities. Always unplug the charger from the power supply when there is no battery pack in the cavity. Unplug charger before attempting to clean.

6.Do not freeze or immerse charger in water or any other liquid.

![]() WARNING: Shock hazard. Don’t allow any liquid to get inside charger. Electric shock may result.

WARNING: Shock hazard. Don’t allow any liquid to get inside charger. Electric shock may result.

![]() CAUTION: Never attempt to open the battery pack for any reason. If the plastic housing of the battery pack breaks or cracks, return to a service center for recycling.

CAUTION: Never attempt to open the battery pack for any reason. If the plastic housing of the battery pack breaks or cracks, return to a service center for recycling.

Storage Recommendations

1.The best storage place is one that is cool and dry away from direct sunlight and excess heat or cold.

2.Long storage will not harm the battery pack or charger. Under proper conditions, they can be stored for 5 years or more.

button,

the tool is run after changing the and does not indicate a problem.

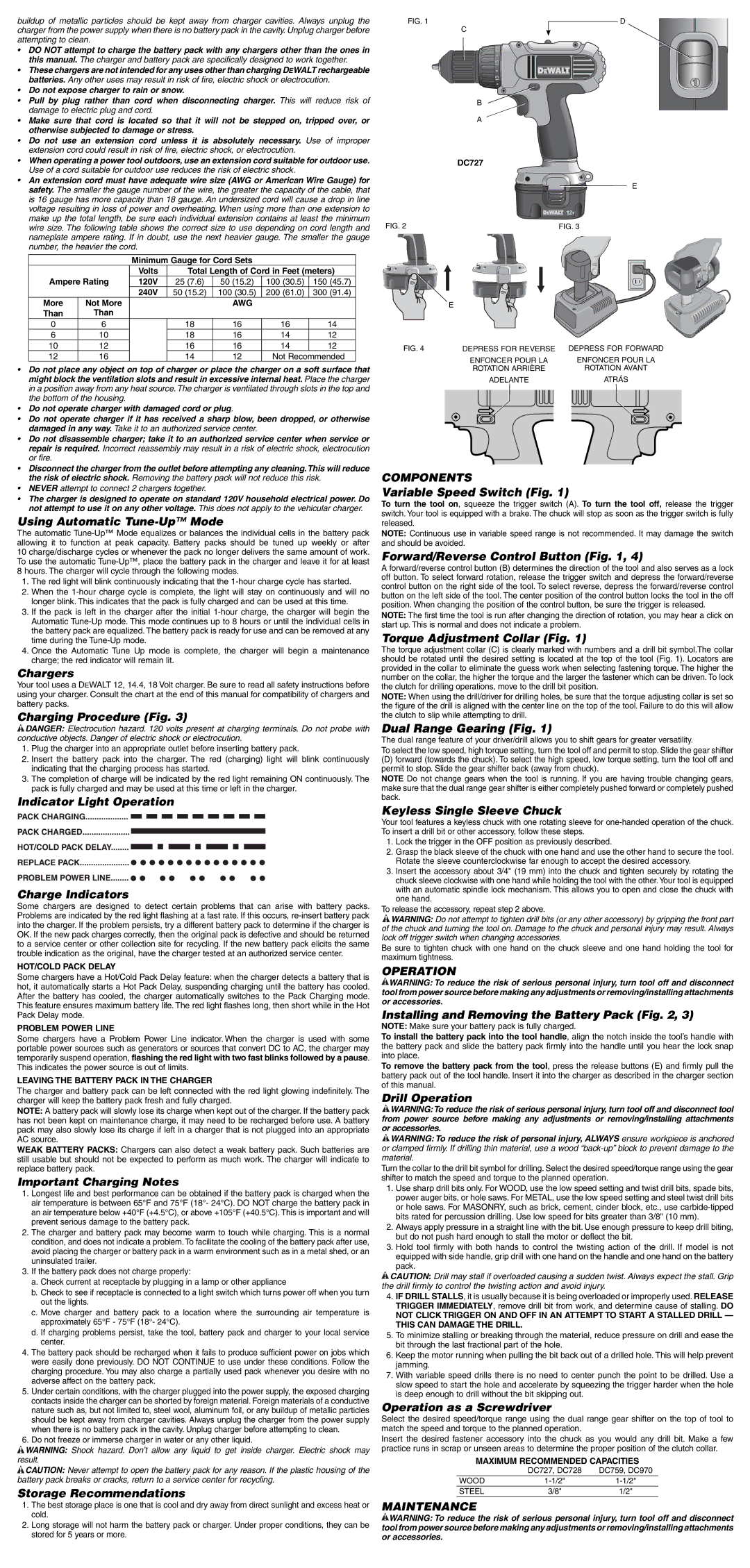

Adjustment Collar (Fig. 1)

The torque adjustment collar (C) is clearly marked with should be rotated until the desired setting is located at the provided in the collar to eliminate the guess work when number on the collar, the higher the torque and the larger the the clutch for drilling operations, move to the drill bit position. NOTE: When using the drill/driver for drilling holes, be sure that the figure of the drill is aligned with the center line on the top of the clutch to slip while attempting to drill.

Dual Range Gearing (Fig. 1)

The dual range feature of your driver/drill allows you to shift gears

To select the low speed, high torque setting, turn the tool off and | . |

(D)forward (towards the chuck). To select the high speed, low permit to stop. Slide the gear shifter back (away from chuck). NOTE Do not change gears when the tool is running. If you are make sure that the dual range gear shifter is either completely pushed back.

Keyless Single Sleeve Chuck

Your tool features a keyless chuck with one rotating sleeve for one-

To insert a drill bit or other accessory, follow these steps.

1.Lock the trigger in the OFF position as previously described.

2.Grasp the black sleeve of the chuck with one hand and use the Rotate the sleeve counterclockwise far enough to accept the

3.Insert the accessory about 3/4" (19 mm) into the chuck and chuck sleeve clockwise with one hand while holding the tool with the with an automatic spindle lock mechanism. This allows you to open one hand.

To release the accessory, repeat step 2 above.

![]() WARNING: Do not attempt to tighten drill bits (or any other accessory)

WARNING: Do not attempt to tighten drill bits (or any other accessory)

of the chuck and turning the tool on. Damage to the chuck and personal. Always lock off trigger switch when changing accessories.

Be sure to tighten chuck with one hand on the chuck sleeve and one hand holding the tool for maximum tightness.

OPERATION

![]() WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect tool from power source before making any adjustments or removing/installing attachments or accessories.

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect tool from power source before making any adjustments or removing/installing attachments or accessories.

Installing and Removing the Battery Pack (Fig. 2, 3)

NOTE: Make sure your battery pack is fully charged.

To install the battery pack into the tool handle, align the notch inside the tool’s handle with the battery pack and slide the battery pack firmly into the handle until you hear the lock snap into place.

To remove the battery pack from the tool, press the release buttons (E) and firmly pull the battery pack out of the tool handle. Insert it into the charger as described in the charger section of this manual.

Drill Operation

![]() WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect tool from power source before making any adjustments or removing/installing attachments or accessories.

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect tool from power source before making any adjustments or removing/installing attachments or accessories.

![]() WARNING: To reduce the risk of personal injury, ALWAYS ensure workpiece is anchored or clamped firmly. If drilling thin material, use a wood

WARNING: To reduce the risk of personal injury, ALWAYS ensure workpiece is anchored or clamped firmly. If drilling thin material, use a wood

Turn the collar to the drill bit symbol for drilling. Select the desired speed/torque range using the gear shifter to match the speed and torque to the planned operation.

1.Use sharp drill bits only. For WOOD, use the low speed setting and twist drill bits, spade bits, power auger bits, or hole saws. For METAL, use the low speed setting and steel twist drill bits or hole saws. For MASONRY, such as brick, cement, cinder block, etc., use

2.Always apply pressure in a straight line with the bit. Use enough pressure to keep drill biting, but do not push hard enough to stall the motor or deflect the bit.

3.Hold tool firmly with both hands to control the twisting action of the drill. If model is not equipped with side handle, grip drill with one hand on the handle and one hand on the battery pack.

![]() CAUTION: Drill may stall if overloaded causing a sudden twist. Always expect the stall. Grip the drill firmly to control the twisting action and avoid injury.

CAUTION: Drill may stall if overloaded causing a sudden twist. Always expect the stall. Grip the drill firmly to control the twisting action and avoid injury.

4.IF DRILL STALLS, it is usually because it is being overloaded or improperly used. RELEASE TRIGGER IMMEDIATELY, remove drill bit from work, and determine cause of stalling. DO

NOT CLICK TRIGGER ON AND OFF IN AN ATTEMPT TO START A STALLED DRILL — THIS CAN DAMAGE THE DRILL.

5.To minimize stalling or breaking through the material, reduce pressure on drill and ease the bit through the last fractional part of the hole.

6.Keep the motor running when pulling the bit back out of a drilled hole. This will help prevent jamming.

7.With variable speed drills there is no need to center punch the point to be drilled. Use a slow speed to start the hole and accelerate by squeezing the trigger harder when the hole is deep enough to drill without the bit skipping out.

Operation as a Screwdriver

Select the desired speed/torque range using the dual range gear shifter on the top of tool to match the speed and torque to the planned operation.

Insert the desired fastener accessory into the chuck as you would any drill bit. Make a few practice runs in scrap or unseen areas to determine the proper position of the clutch collar.

MAXIMUM RECOMMENDED CAPACITIES

| DC727, DC728 | DC759, DC970 |

WOOD | ||

STEEL | 3/8" | 1/2" |

MAINTENANCE

![]() WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect tool from power source before making any adjustments or removing/installing attachments or accessories.

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect tool from power source before making any adjustments or removing/installing attachments or accessories.