English

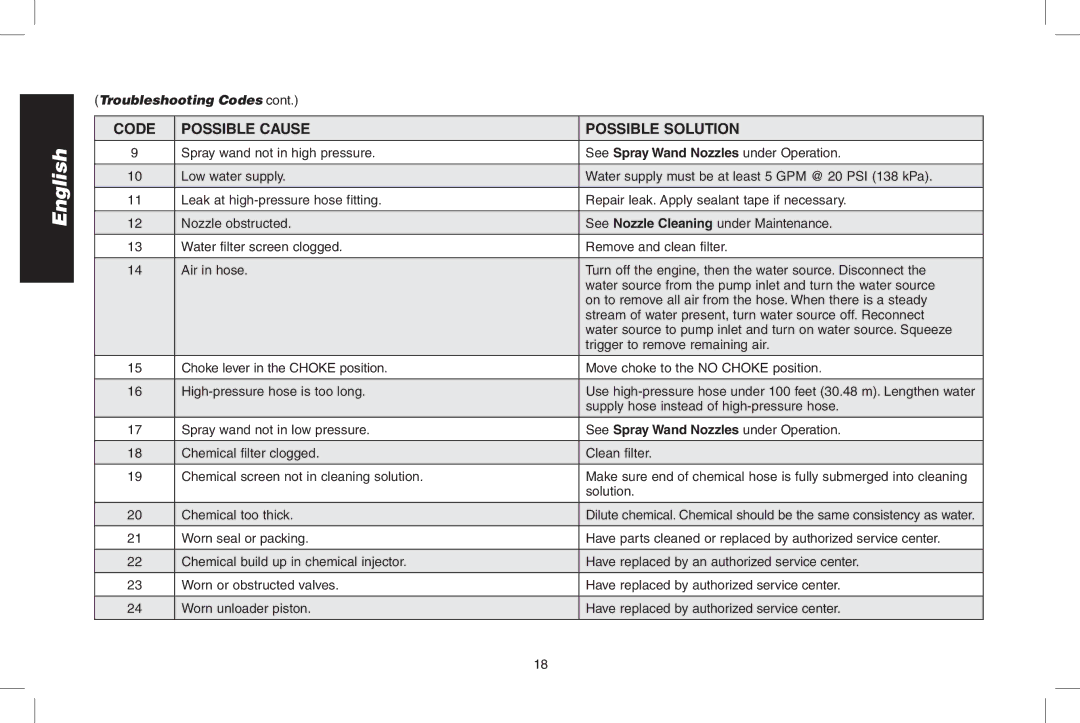

(Troubleshooting Codes cont.)

Code | possible cause | POSSIBLE SOLUTION |

|

|

|

9 | Spray wand not in high pressure. | See Spray Wand Nozzles under Operation. |

|

|

|

10 | Low water supply. | Water supply must be at least 5 GPM @ 20 PSI (138 kPa). |

|

|

|

11 | Leak at | Repair leak. Apply sealant tape if necessary. |

|

|

|

12 | Nozzle obstructed. | See Nozzle Cleaning under Maintenance. |

|

|

|

13 | Water filter screen clogged. | Remove and clean filter. |

|

|

|

14 | Air in hose. | Turn off the engine, then the water source. Disconnect the |

|

| water source from the pump inlet and turn the water source |

|

| on to remove all air from the hose. When there is a steady |

|

| stream of water present, turn water source off. Reconnect |

|

| water source to pump inlet and turn on water source. Squeeze |

|

| trigger to remove remaining air. |

|

|

|

15 | Choke lever in the Choke position. | Move choke to the No Choke position. |

|

|

|

16 | Use | |

|

| supply hose instead of |

|

|

|

17 | Spray wand not in low pressure. | See Spray Wand Nozzles under Operation. |

|

|

|

18 | Chemical filter clogged. | Clean filter. |

|

|

|

19 | Chemical screen not in cleaning solution. | Make sure end of chemical hose is fully submerged into cleaning |

|

| solution. |

|

|

|

20 | Chemical too thick. | Dilute chemical. Chemical should be the same consistency as water. |

|

|

|

21 | Worn seal or packing. | Have parts cleaned or replaced by authorized service center. |

|

|

|

22 | Chemical build up in chemical injector. | Have replaced by an authorized service center. |

|

|

|

23 | Worn or obstructed valves. | Have replaced by authorized service center. |

|

|

|

24 | Worn unloader piston. | Have replaced by authorized service center. |

|

|

|

18