5.Turn the saw on, press it down to the set cutting depth and cut the

![]() WARNING: To reduce the risk of injury, ALWAYS secure the track (W) with a clamp.

WARNING: To reduce the risk of injury, ALWAYS secure the track (W) with a clamp.

Speed Adjustment (Fig. 1)

The speed can be regulated between 1750 and 4000/min using the speed wheel (S). This enables you to optimise the cutting speed to suit the material. Refer to the following chart for type of material and speed range.

TYPE OF MATERIAL TO BE CUT | SPEED RANGE |

Solid wood (hard, soft) | |

Chipboards | |

Laminated wood, blockboards, | |

veneered and coated boards |

|

Paper and carton |

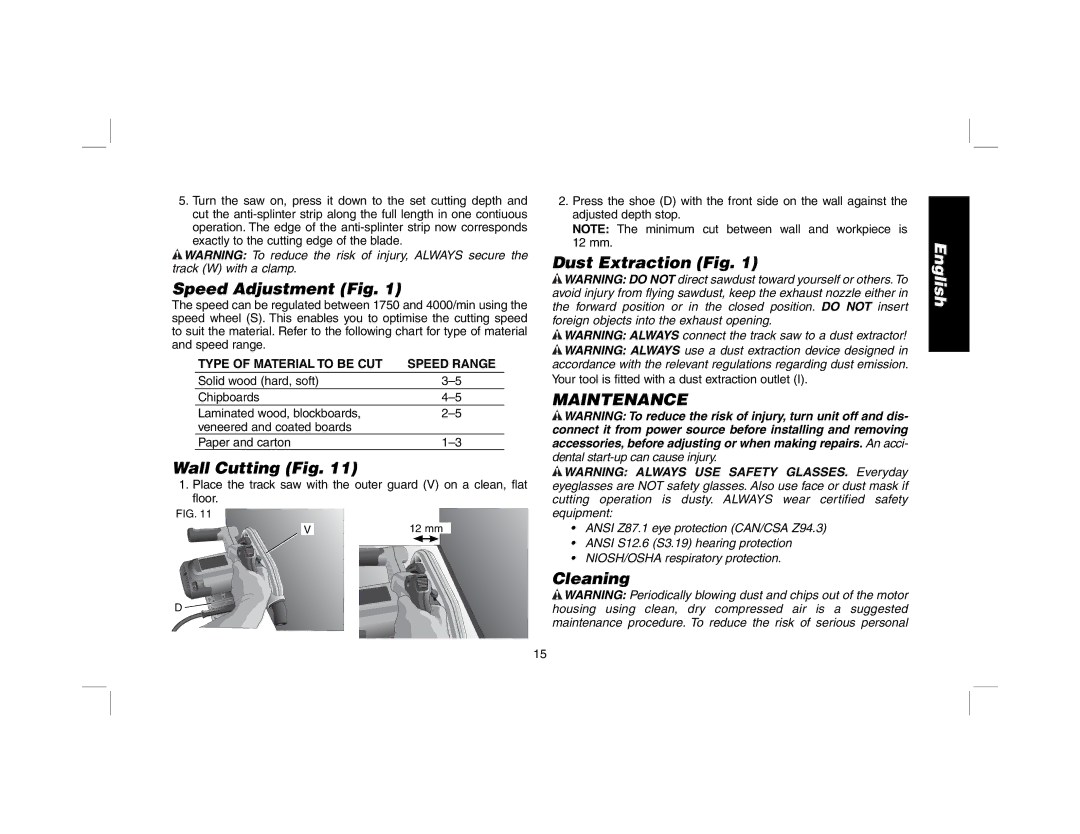

Wall Cutting (Fig. 11)

1.Place the track saw with the outer guard (V) on a clean, flat floor.

FIG. 11

V |

| 12 mm |

|

|

|

D ![]()

![]()

2.Press the shoe (D) with the front side on the wall against the adjusted depth stop.

NOTE: The minimum cut between wall and workpiece is 12 mm.

Dust Extraction (Fig. 1)

![]() WARNING: DO NOT direct sawdust toward yourself or others. To avoid injury from flying sawdust, keep the exhaust nozzle either in the forward position or in the closed position. DO NOT insert foreign objects into the exhaust opening.

WARNING: DO NOT direct sawdust toward yourself or others. To avoid injury from flying sawdust, keep the exhaust nozzle either in the forward position or in the closed position. DO NOT insert foreign objects into the exhaust opening.

![]() WARNING: ALWAYS connect the track saw to a dust extractor!

WARNING: ALWAYS connect the track saw to a dust extractor! ![]() WARNING: ALWAYS use a dust extraction device designed in accordance with the relevant regulations regarding dust emission.

WARNING: ALWAYS use a dust extraction device designed in accordance with the relevant regulations regarding dust emission.

Your tool is fitted with a dust extraction outlet (I).

MAINTENANCE

![]() WARNING: To reduce the risk of injury, turn unit off and dis- connect it from power source before installing and removing accessories, before adjusting or when making repairs. An acci- dental

WARNING: To reduce the risk of injury, turn unit off and dis- connect it from power source before installing and removing accessories, before adjusting or when making repairs. An acci- dental

![]() WARNING: ALWAYS USE SAFETY GLASSES. Everyday eyeglasses are NOT safety glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS wear certified safety equipment:

WARNING: ALWAYS USE SAFETY GLASSES. Everyday eyeglasses are NOT safety glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS wear certified safety equipment:

•ANSI Z87.1 eye protection (CAN/CSA Z94.3)

•ANSI S12.6 (S3.19) hearing protection

•NIOSH/OSHA respiratory protection.

Cleaning

![]() WARNING: Periodically blowing dust and chips out of the motor housing using clean, dry compressed air is a suggested maintenance procedure. To reduce the risk of serious personal

WARNING: Periodically blowing dust and chips out of the motor housing using clean, dry compressed air is a suggested maintenance procedure. To reduce the risk of serious personal

15

English