ASSEMBLY

ASSEMBLY TOOLS REQUIRED

* M6 Allen wrench (supplied) * Flathead Screwdriver (Not Supplied * Forklift and Lifting Straps For

ASSEMBLY TIME ESTIMATE -

UNPACKING AND CLEANING

Remove the bolts that fasten the machine to the ship- ping skid.

Two lifting lugs are built into the machine, one of which is shown at (A) Fig. 4. These lugs can be used to mechanically lift the machine using a forklift and lifting straps. NOTE: The other lifting lug is located at the rear and the opposite end of the machine. Carefully remove the planer from the shipping skid.

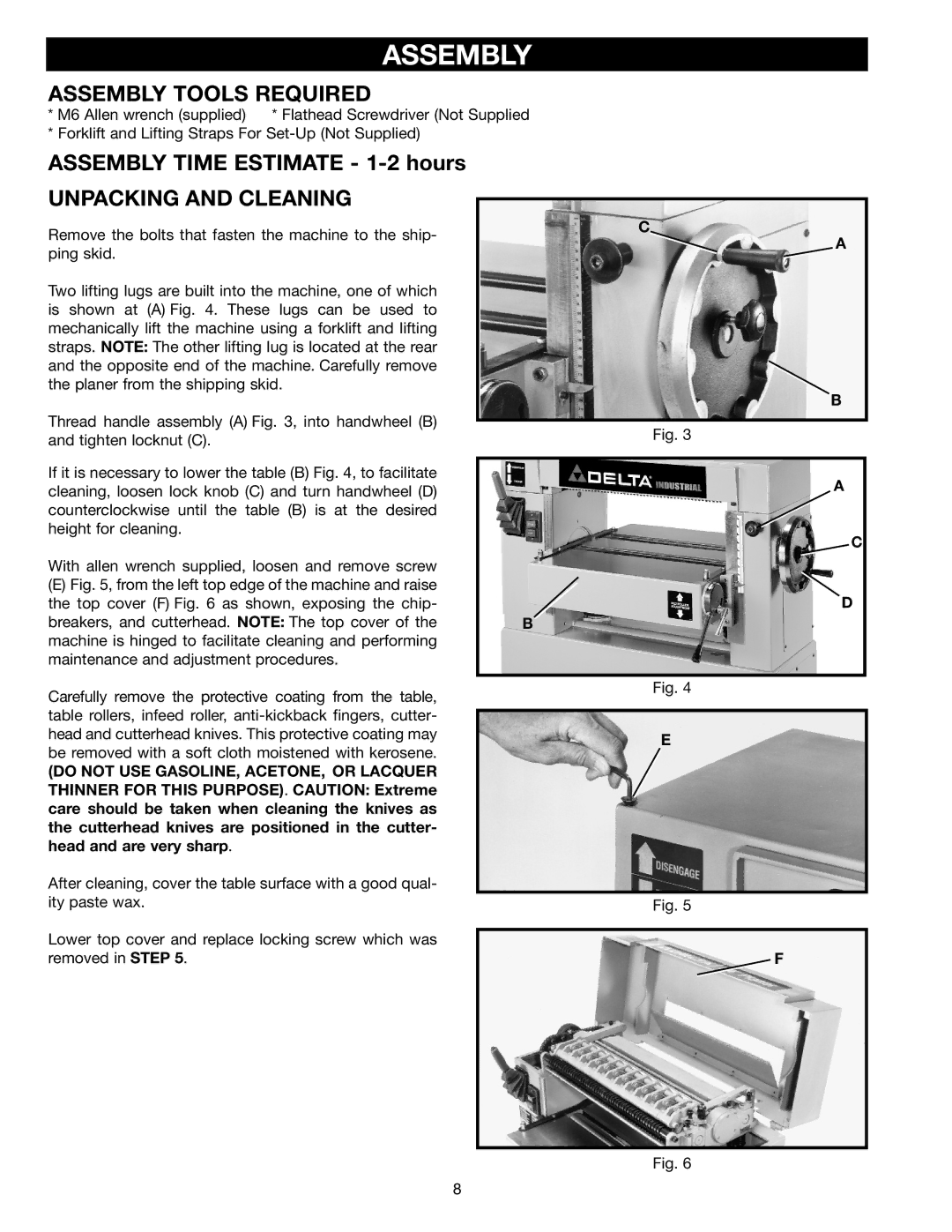

Thread handle assembly (A) Fig. 3, into handwheel (B) and tighten locknut (C).

If it is necessary to lower the table (B) Fig. 4, to facilitate cleaning, loosen lock knob (C) and turn handwheel (D) counterclockwise until the table (B) is at the desired height for cleaning.

With allen wrench supplied, loosen and remove screw

(E)Fig. 5, from the left top edge of the machine and raise the top cover (F) Fig. 6 as shown, exposing the chip- breakers, and cutterhead. NOTE: The top cover of the machine is hinged to facilitate cleaning and performing maintenance and adjustment procedures.

C

A

B

Fig. 3

A

C

D

B

Carefully remove the protective coating from the table, table rollers, infeed roller, anti-kickback fingers, cutter- head and cutterhead knives. This protective coating may be removed with a soft cloth moistened with kerosene.

(DO NOT USE GASOLINE, ACETONE, OR LACQUER THINNER FOR THIS PURPOSE). CAUTION: Extreme care should be taken when cleaning the knives as the cutterhead knives are positioned in the cutter- head and are very sharp.

After cleaning, cover the table surface with a good qual- ity paste wax.

Lower top cover and replace locking screw which was removed in STEP 5.

Fig. 4

E

Fig. 5

F

Fig. 6

8