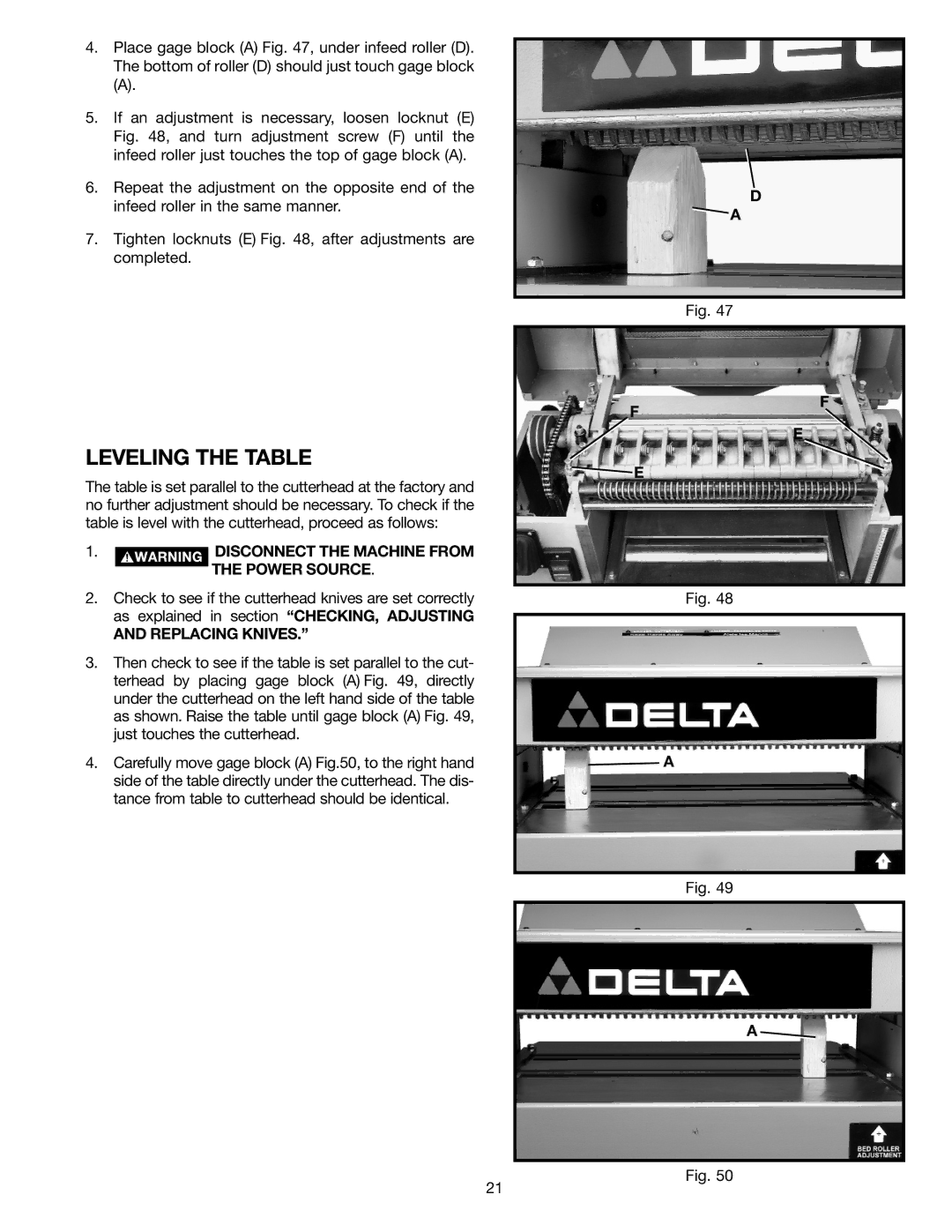

4.Place gage block (A) Fig. 47, under infeed roller (D). The bottom of roller (D) should just touch gage block

(A).

5.If an adjustment is necessary, loosen locknut (E) Fig. 48, and turn adjustment screw (F) until the infeed roller just touches the top of gage block (A).

6.Repeat the adjustment on the opposite end of the infeed roller in the same manner.

7.Tighten locknuts (E) Fig. 48, after adjustments are completed.

D

![]() A

A

Fig. 47

F

F

LEVELING THE TABLE

The table is set parallel to the cutterhead at the factory and no further adjustment should be necessary. To check if the table is level with the cutterhead, proceed as follows:

1. |

|

|

| DISCONNECT THE MACHINE FROM |

|

|

| ||

|

|

| ||

|

|

|

| THE POWER SOURCE. |

|

|

|

|

2.Check to see if the cutterhead knives are set correctly as explained in section “CHECKING, ADJUSTING

AND REPLACING KNIVES.”

3.Then check to see if the table is set parallel to the cut- terhead by placing gage block (A) Fig. 49, directly under the cutterhead on the left hand side of the table as shown. Raise the table until gage block (A) Fig. 49, just touches the cutterhead.

4.Carefully move gage block (A) Fig.50, to the right hand side of the table directly under the cutterhead. The dis- tance from table to cutterhead should be identical.

E

![]() E

E

Fig. 48

![]() A

A

Fig. 49

A ![]()

Fig. 50

21